Early-strength polycarboxylate type high-performance water reducing agent and preparation method

A polycarboxylate-based, high-performance technology, applied in the field of early-strength polycarboxylate-based high-performance water reducer and its preparation, can solve problems such as slow development of early strength, and achieve simplified process, high water reduction rate, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

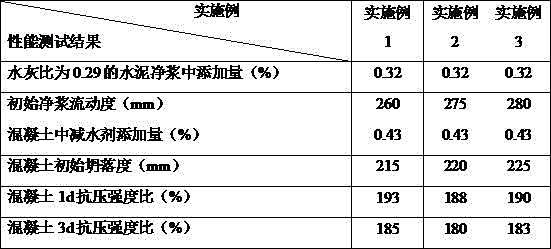

Embodiment 1

[0052]An early-strength polycarboxylate-based high-performance water reducer, composed of methallyl polyoxyethylene ether 100, acrylic acid 10, maleic anhydride 5, 2-acrylamide-2-methylpropane Sulfonic acid 5, sodium methacrylate sulfonate 0, hydrogen peroxide 2.1, ammonium persulfate 0.5, L-ascorbic acid 0.23, sodium formaldehyde sulfoxylate dihydrate 0.08, mercaptoacetic acid 0, mercaptopropionic acid 0.39, sodium hydroxide 14 and water 180 compositions.

[0053] The synthesis steps of the water reducer are as follows:

[0054] 1) Take methallyl polyoxyethylene ether, acrylic acid, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, sodium methacrylsulfonate, hydrogen peroxide, ammonium persulfate, L-Ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, thioglycolic acid, mercaptopropionic acid, sodium hydroxide and water.

[0055] 2) Put methallyl polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium methacrylate sulfonate and water accounting...

Embodiment 2

[0061] An early-strength polycarboxylate-based high-performance water reducer, composed of methallyl polyoxyethylene ether 100, acrylic acid 6, maleic anhydride 6, 2-acrylamide-2-methylpropane by weight ratio Sulfonic acid 0, sodium methacrylate sulfonate 3, hydrogen peroxide 1.1, ammonium persulfate 2.3, L-ascorbic acid 0.05, sodium formaldehyde sulfoxylate dihydrate 0.05, thioglycolic acid 0.19, mercaptopropionic acid 0, sodium hydroxide 10 and water 110 compositions.

[0062] The synthesis steps of the water reducer are as follows:

[0063] 1) Take methallyl polyoxyethylene ether, acrylic acid, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, sodium methacrylsulfonate, hydrogen peroxide, ammonium persulfate, L-Ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, thioglycolic acid, mercaptopropionic acid, sodium hydroxide and water.

[0064] 2) Put methallyl polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium methacrylate sulfonate and wa...

Embodiment 3

[0070] An early-strength polycarboxylic acid-based high-performance water reducer, composed of methallyl polyoxyethylene ether 100, acrylic acid 5, maleic anhydride 10, 2-acrylamide-2-methylpropane Sulfonic acid 10, sodium methacrylate sulfonate 5, hydrogen peroxide 2.5, ammonium persulfate 2.8, L-ascorbic acid 0.25, sodium formaldehyde sulfoxylate dihydrate 0.25, thioglycolic acid 0.5, mercaptopropionic acid 0.5, sodium hydroxide 20 and water 200 compositions.

[0071] The synthesis steps of the water reducer are as follows:

[0072] 1) Take methallyl polyoxyethylene ether, acrylic acid, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, sodium methacrylsulfonate, hydrogen peroxide, ammonium persulfate, L-Ascorbic acid, sodium formaldehyde sulfoxylate dihydrate, thioglycolic acid, mercaptopropionic acid, sodium hydroxide and water.

[0073] 2) Put methallyl polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium methacrylate sulfonate and water accou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com