Preparation and application of morphology-adjustable hollow cage-shaped Mn/Fe oxide nano material

A technology of nanomaterials and oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, nanotechnology for materials and surface science, etc., can solve the problem of large amount of catalysts and incomplete degradation and other problems, to achieve the effect of less environmental pollution, significant catalytic effect, and catalytic effect recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

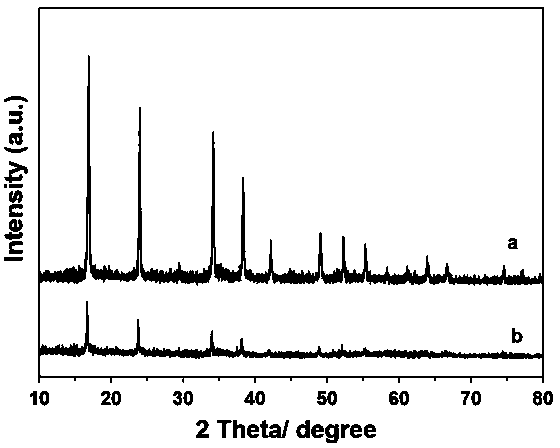

[0031] Preparation of hollow dice-like Mn / Fe oxide nanomaterials:

[0032] (1) Dissolve 0.6 g of PVP in a mixed solution of 20 mL of water and 20 mL of ethanol until completely dissolved;

[0033] (2) Dissolve 0.063 g of manganese sulfate monohydrate and 0.0159 g of ferric sulfate in the solution of step (1), stir at room temperature for 15 min, and then sonicate for 10 min;

[0034] (3) 0.132 g of potassium ferricyanide (K 3 [Fe(CN) 6 ]) was dissolved in 20 mL of water until completely dissolved;

[0035] (4) Add the solution of step (3) to the solution of step (2), stir at room temperature for 1 h, wash with ethanol solution for 3 times, and wash with water for 1 time, place in the refrigerator for 1 h, and place in freeze-dry Dry in the machine for 2-3 h to obtain the Mn / Fe-like Prussian blue precursor;

[0036] (5) 0.033 g of the Prussian blue-like precursor synthesized in step (4) was dissolved in 25 mL of water and ultrasonicated for 20 min to obtain a homogeneous so...

Embodiment 2

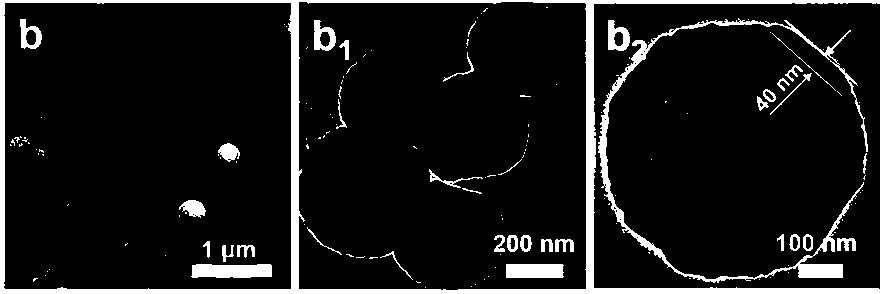

[0041] Preparation of hollow spherical Mn / Fe oxide nanomaterials:

[0042] (1) Dissolve 0.6 g of PVP in a mixed solution of 20 mL of water and 20 mL of ethanol until completely dissolved;

[0043](2) Dissolve 0.036 g of manganese sulfate monohydrate and 0.0319 g of ferric sulfate in the solution of step (1), stir at room temperature for 15 min and then sonicate for 10 min;

[0044] (3) 0.132 g of potassium ferricyanide (K 3 [Fe(CN) 6 ]) was dissolved in 20 mL of water until completely dissolved;

[0045] (4) Add the solution of step (3) to the solution of step (2), stir at room temperature for 1 h, wash with ethanol solution for 3 times, and wash with water for 1 time, place in the refrigerator for 1 h, and place in freeze-dry Dry in the machine for 2-3 h to obtain the Mn / Fe-like Prussian blue precursor;

[0046] (5) 0.033 g of the Prussian blue-like precursor synthesized in step (4) was dissolved in 25 mL of water and ultrasonicated for 20 min to obtain a homogeneous solu...

Embodiment 3

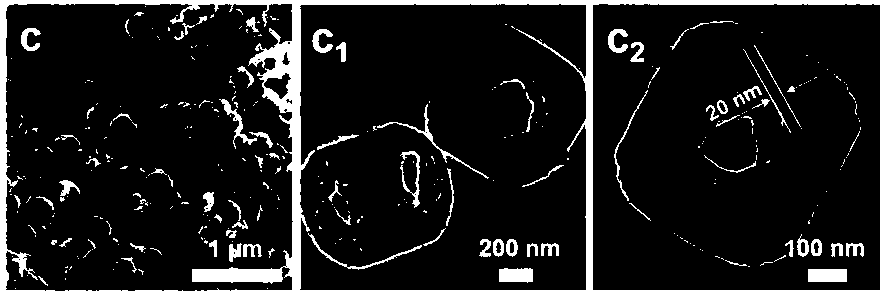

[0051] Preparation of hollow octahedral Mn / Fe oxide nanomaterials:

[0052] (1) Dissolve 0.6 g of PVP in a mixed solution of 20 mL of water and 20 mL of ethanol until completely dissolved;

[0053] (2) Dissolve 0.027 g of manganese sulfate monohydrate and 0.0372 g of ferric sulfate in the solution of step (1), stir at room temperature for 15 min, and then sonicate for 10 min;

[0054] (3) 0.132 g of potassium ferricyanide (K 3 [Fe(CN) 6 ]) was dissolved in 20 mL of water until completely dissolved;

[0055] (4) Add the solution of step (3) to the solution of step (2), stir at room temperature for 1 h, wash with ethanol solution for 3 times, and wash with water for 1 time, place in the refrigerator for 1 h, and place in freeze-dry Dry in the machine for 2-3 h to obtain the Mn / Fe-like Prussian blue precursor;

[0056] (5) 0.033 g of the Prussian blue-like precursor synthesized in step (4) was dissolved in 25 mL of water and ultrasonicated for 20 min to obtain a homogeneous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com