Polycarboxylic acid-series water reducing agent with ultrahigh water absorbing capacity and preparation method and use method thereof

A polycarboxylate-based, water-reducing technology, applied in the field of polycarboxylate-based water-reducers, can solve problems such as product supply and price fluctuations, high raw material costs, and unsatisfactory conditions, so as to broaden the raw material supply market and improve The effect of concrete strength and good fluidity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

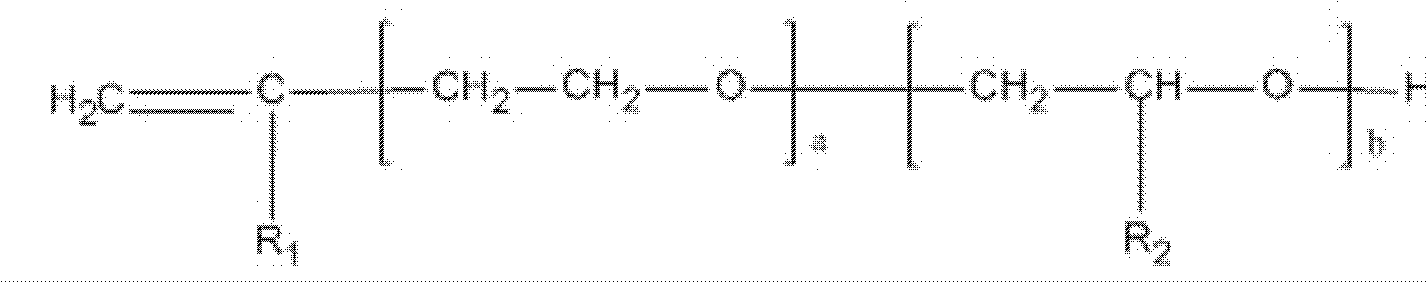

Method used

Image

Examples

Embodiment 1

[0045] According to the following steps to prepare the polycarboxylate water reducer of the present invention with super high water reducing rate

[0046] ①Preparation before polymerization

[0047] Accurately weigh 175 parts by weight of water for use in the following steps;

[0048] Preparation of a solution a

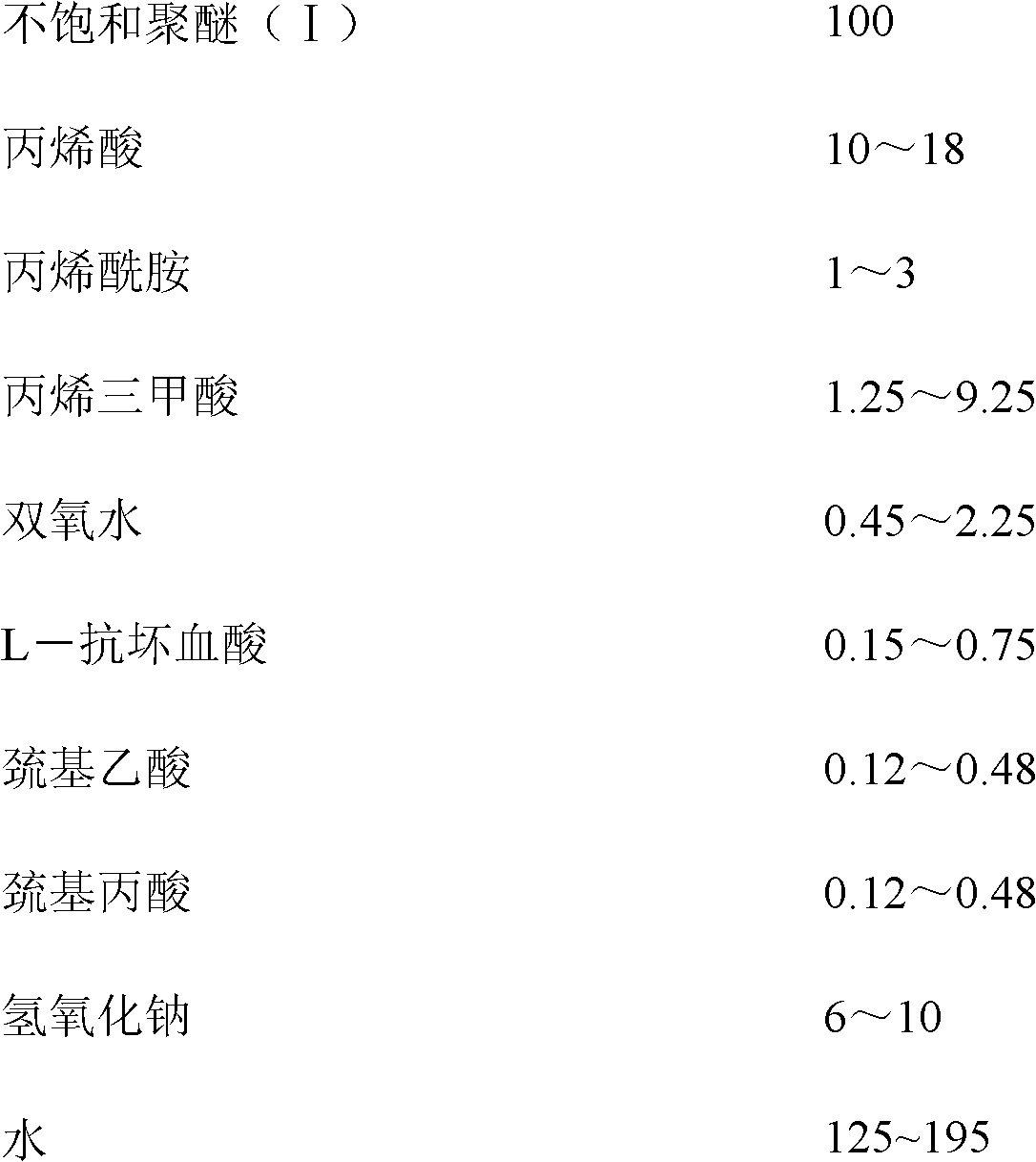

[0049] Accurately weigh 18 parts by weight of acrylic acid, 3 parts by weight of acrylamide, 9.25 parts by weight of acrylic tricarboxylic acid and part of water, stir and mix evenly, pump into the high level tank A, and prepare dropwise;

[0050] Preparation of b solution b

[0051] Accurately weigh 0.30 parts by weight of L-ascorbic acid, 0.36 parts by weight of mercaptoacetic acid, 0.24 parts by weight of mercaptopropionic acid and part of water, stir and mix evenly, pump into the high level tank B, and prepare dropwise;

[0052] c Preparation of base material

[0053] Accurately weigh 100 parts by weight of unsaturated polyether DD-405 with a number average mol...

Embodiment 2~ Embodiment 5

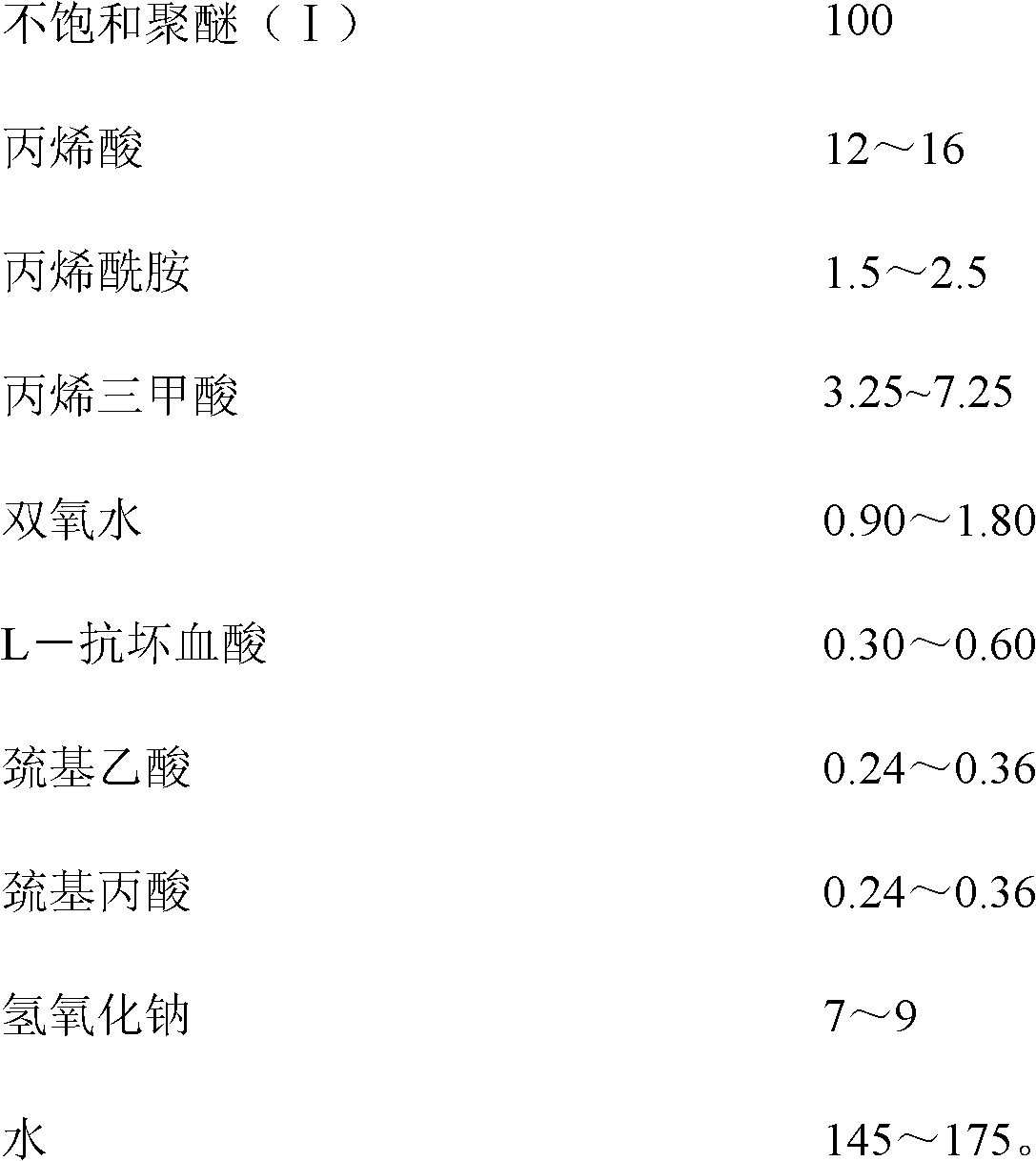

[0060] According to the method and steps of Example 1, according to the formulation in Table 1, the polycarboxylate water reducer with super high water reducing rate of the present invention and its use method were prepared.

[0061] Table 1

[0062] Raw materials and technical indicators

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com