Preparation method and application of three-dimensional hollow multilevel-structured stannic oxide gas-sensitive material

A gas-sensitive material and three-dimensional hollow technology, which is applied in the preparation and application of nanomaterials, can solve the problems of complex process, high cost of raw materials, unsuitable for mass production, etc., and achieve the effect of low cost, environmental friendliness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 5 mg of C template in 45 mL of deionized water and ultrasonically disperse evenly, add 10 mL of thioglycolic acid, 0.5 mL of hydrochloric acid, 0.3 g of stannous chloride, and 0.5 g of urea in sequence, and stir to form a uniform mixed solution. Then, the obtained solution was transferred to a 100mL reaction kettle, and heated to 140°C in an oven for 6 hours to react; after the reaction was completed, the reaction kettle was taken out and cooled to room temperature under air, and the product was transferred to a centrifuge tube.

[0026] (2) The product was washed with deionized water and ethanol for 2-3 times each. After centrifugation, the precipitate was transferred to a petri dish and dried in an oven at 60°C for 24 hours to obtain a dark gray precursor.

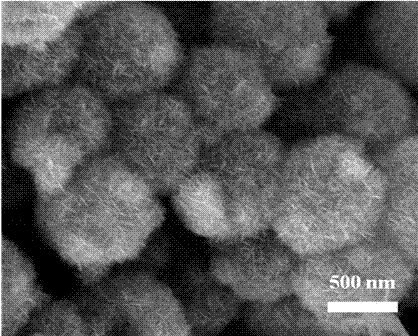

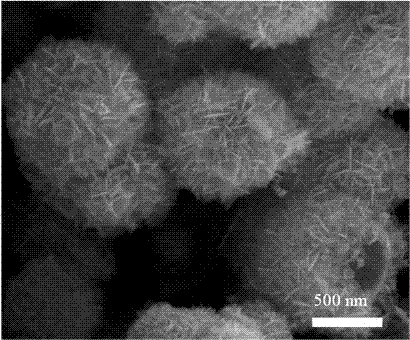

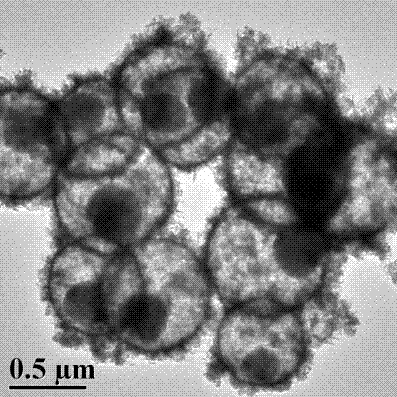

[0027] (3) Put the tin oxide into a muffle furnace, raise the temperature at 1°C / min to 550°C for 5 hours, and then obtain off-white tin oxide powder with a three-dimensional sheet-like hollow multi-level ...

Embodiment 2

[0030] (1) Take the C template and disperse it evenly in deionized water by ultrasonic, add thioglycolic acid, hydrochloric acid, stannous chloride, and urea in sequence, and stir to form a uniform mixed solution. The concentration of added C template is 0.067mg / mL, the concentration of stannous chloride is 0.3mol / L, the volume ratio of stannous chloride solution and thioglycolic acid is 4500:1, and the volume ratio of stannous chloride solution and hydrochloric acid is 90 : 1; The mol ratio of described urea and stannous chloride is 3: 1. The obtained solution was transferred to a 100mL reaction kettle, and heated to 140°C in an oven for 8 hours to react; after the reaction was completed, the reaction kettle was taken out and cooled to room temperature under air, and the product was transferred to a centrifuge tube.

[0031] (2) The product was washed with deionized water and ethanol for 2-3 times each. After centrifugation, the precipitate was transferred to a petri dish and...

Embodiment 3

[0034] (1) Take the C template and disperse it evenly in deionized water by ultrasonic, add thioglycolic acid, hydrochloric acid, stannous chloride, and urea in sequence, and stir to form a uniform mixed solution. The concentration of C template added is 0.089mg / mL, the concentration of stannous chloride is 0.3mol / L, the volume ratio of stannous chloride solution and thioglycolic acid is 4500:1, and the volume ratio of stannous chloride solution and hydrochloric acid is 90 : 1; The mol ratio of described urea and stannous chloride is 4: 1. The obtained solution was transferred to a 100mL reaction kettle, and heated to 160°C in an oven for 6 hours to react; after the reaction was completed, the reaction kettle was taken out and cooled to room temperature under air, and the product was transferred to a centrifuge tube.

[0035] (2) The product was washed with deionized water and ethanol for 2-3 times each. After centrifugation, the precipitate was transferred to a petri dish and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com