Preparation method of magnetic graphene ternary composites based on click chemistry

A technology of magnetic graphene and composite materials, applied in the field of graphene, which can solve the problems of difficult solid-liquid phase separation, irregular shape, and uneven particle size, and achieve regular shape, uniform particle size, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Magnetic Fe 3 o 4 preparation of

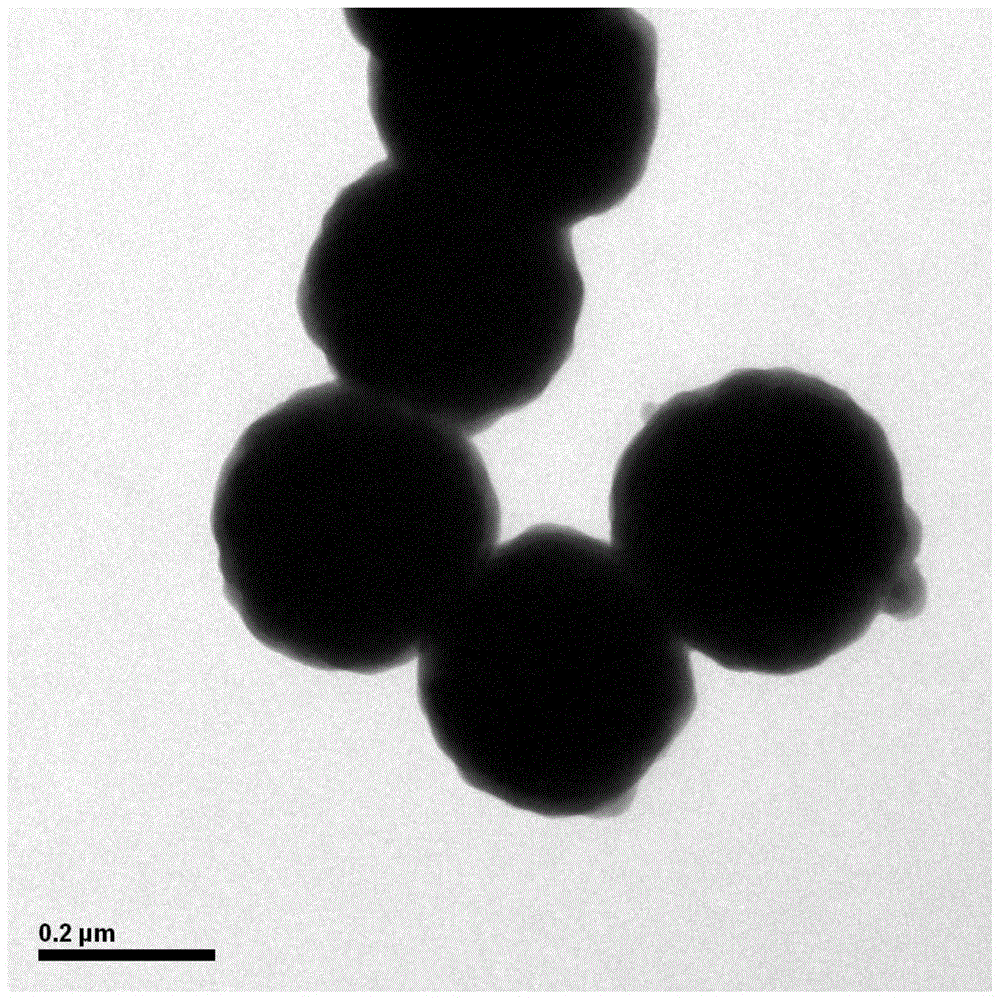

[0023] 1.0g FeCl 3 ·6H 2 O was added to 20mL of ethylene glycol, ultrasonically dispersed at 50°C for 0.5h until the solution was clear; then 3.0g of anhydrous sodium acetate was added, ultrasonically dispersed at 50°C for 0.5h, and then the mixed solution was added to a polytetrafluoroethylene autoclave Reaction at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water to pH 7.0, then wash several times with ethanol, and vacuum dry at 60°C for 6 hours to obtain magnetic Fe 3 o 4 . Produced Fe 3 o 4 The TEM image of figure 1 As shown, Fe prepared by traditional solvothermal method 3 o 4 The particle size is 300-500nm.

Embodiment 2

[0024] Embodiment 2: magnetic nanometer Fe 3 o 4

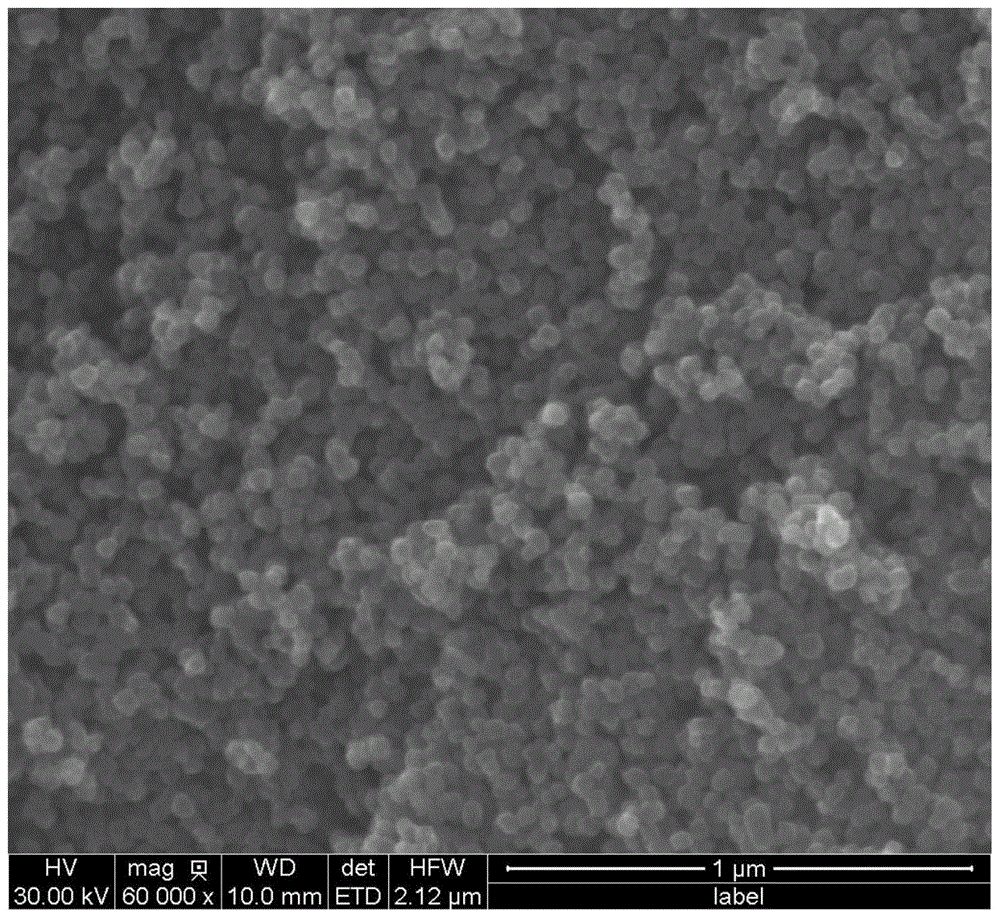

[0025] 1.0g FeCl 3 ·6H 2 Add O to 20mL of ethylene glycol, ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add 3.0g of anhydrous sodium acetate, ultrasonically disperse at 50°C for 0.5h, then add 0.4g of sodium hydroxide and 10.0mL of ethylenediamine , ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add the mixed solution into a polytetrafluoroethylene autoclave and react at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water until the pH is 7.0, then wash several times with ethanol, and vacuum dry at 60°C for 6 hours to obtain magnetic nano-Fe 3 o 4 . The prepared magnetic nano-Fe 3 o 4 The scanning electron microscope image of figure 2 As shown, the Fe prepared by the modified solvothermal method 3 o 4 The particle size is 50-60nm, with regular shape, uniform particle size and good dispersion.

Embodiment 3

[0026] Example 3: Preparation of Amino-modified Magnetic Graphene Ternary Composite Material

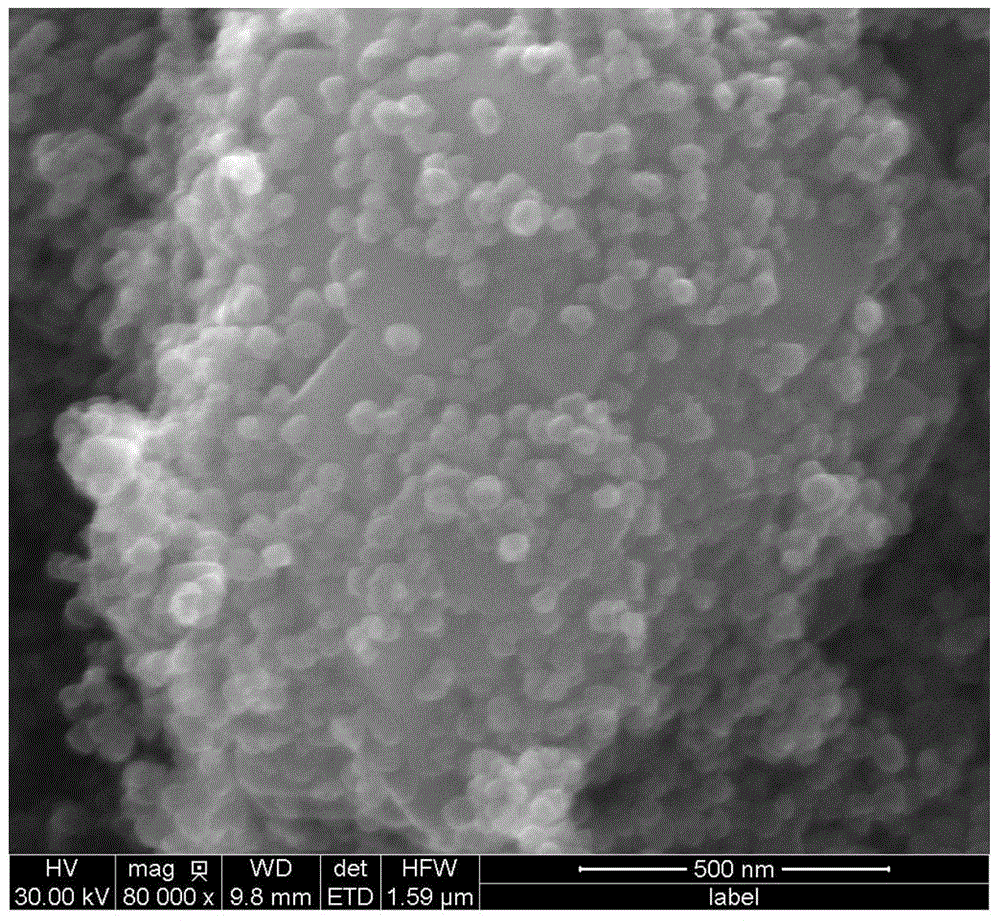

[0027] 1.0g FeCl 3 ·6H 2Add O to 20mL of ethylene glycol, ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add 3.0g of anhydrous sodium acetate, ultrasonically disperse at 50°C for 0.5h, then add 0.4g of sodium hydroxide and 10.0mL of ethylenediamine , ultrasonically disperse at 50°C for 0.5h until the solution is clear; add 50mg of carboxylated graphene, ultrasonically disperse at 50°C for 1h, then add the mixed solution into a polytetrafluoroethylene autoclave at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water until the pH is 7.0, then wash several times with ethanol, and dry in vacuum at 60°C for 6 hours to obtain an amino-modified magnetic graphene ternary composite. The scanning electron microscope picture of the above-mentioned amino modified magnetic graphene ternary composite material is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com