Polymethacrylic acid magnetic composite microspheres and preparation method thereof

A technology of magnetic composite microspheres and polymethacrylic acid, applied in the field of polymers, to achieve the effects of convenient operation, great flexibility, simple equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

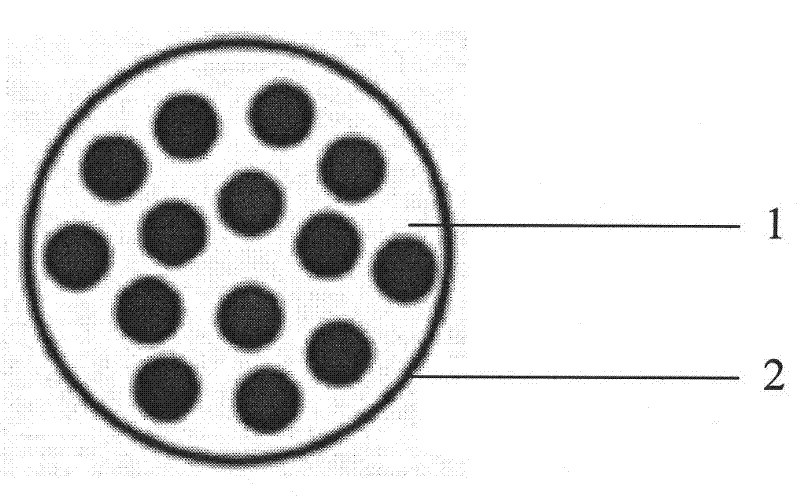

Method used

Image

Examples

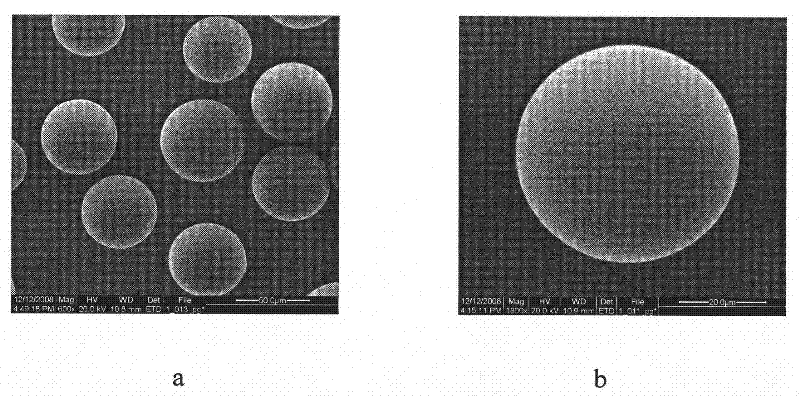

Embodiment 1

[0033] 1) In a three-neck flask equipped with an electric stirrer, dissolve 0.5g of Span80 in 60ml of toluene, under the condition of nitrogen protection, the system reacts for 30min while stirring, and the reaction temperature is 20°C;

[0034] 2) Under the condition of nitrogen protection, dissolve 1ml of methacrylic acid and 0.1g of N,N'-methylene bisacrylamide in 5ml of secondary water to prepare a solution, and add the solution to the system of step 1) , then add 1ml (5 ~ 100mg / ml) of Fe 3 o 4 , and 1ml of potassium persulfate, the system reacted for 10 minutes while stirring, and the reaction temperature was 30°C;

[0035] 3) Under the condition of nitrogen protection, add 1ml of tetramethylethylenediamine dropwise to the system of step 2), react at 40°C for 2h, and wash repeatedly with secondary water and ethanol to obtain polymethacrylic acid magnetic Composite microspheres.

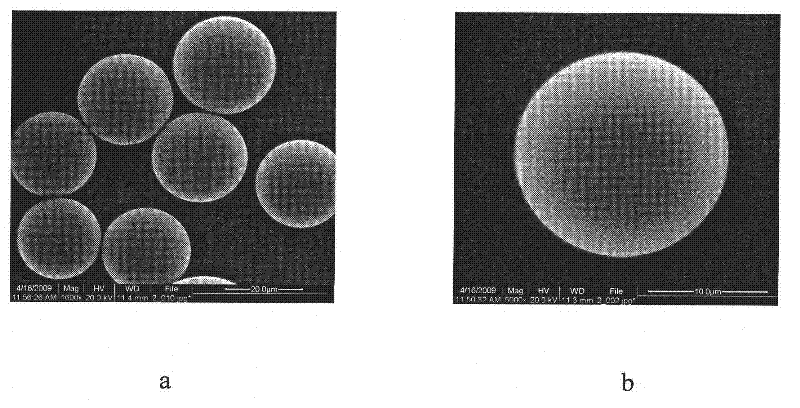

Embodiment 2

[0038] 1) In a three-neck flask equipped with an electric stirrer, dissolve 0.4g Span80 in 60ml of toluene, under the condition of nitrogen protection, the system reacts for 30min while stirring, and the reaction temperature is 20°C;

[0039] 2) Under the condition of nitrogen protection, dissolve 1ml of methacrylic acid and 0.15g of N,N'-methylenebisacrylamide in 5ml of secondary water to prepare a solution, and add the solution to the system of step 1) , then add 1ml (5 ~ 100mg / ml) of Fe 3 o 4 , and 1ml of potassium persulfate, the system reacted for 30 minutes while stirring, and the reaction temperature was 20°C;

[0040] 3) Under the condition of nitrogen protection, add 1ml of tetrabutylammonium bromide dropwise to the system of step 2), react at 40°C for 3h, and wash repeatedly with secondary water and ethanol to obtain polymethacrylic acid magnetic Composite microspheres.

[0041] image 3 (a), (b) is the scanning electron micrograph of the polymethacrylic acid mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com