Preparation method of magnetic nanometer molecular imprinting composite material related to estrogen

A magnetic molecular imprinting and magnetic nanotechnology, which is applied in the field of preparation of amino-functional nano-ferric oxide magnetic molecular imprinting composite materials, can solve the problems of limited active sites, cumbersome operation, weak adsorption, etc. The effect of control, simple preparation process and shortened reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

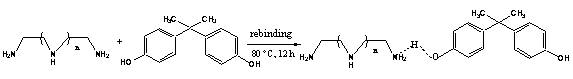

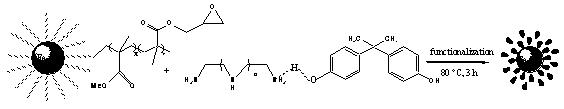

[0022] The preparation method of the magnetic nano molecular imprinted composite material of estrogen in the present invention comprises the following steps:

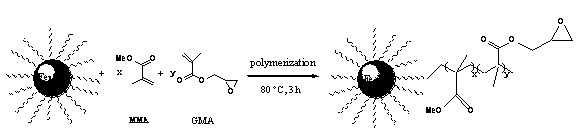

[0023] 1. Preparation of monodisperse Fe3O4 / polymer composite microspheres with high magnetic content: Nano-Fe3O4 particles were prepared by chemical co-precipitation method, and the surface was modified with oleic acid, and then prepared by suspension polymerization method. Ferric oxide / polymer composite microspheres with monodisperse magnetic content; specifically include the following sub-steps:

[0024] 1.1. Preparation of nanometer iron ferric oxide particles: dissolving divalent iron salt and ferric salt in water, the concentration of ferrous salt is 0.1-0.4mol / L, and the concentration of ferric salt is 0.2-0.8mol / L; After ultrasonic dispersion for 1-10 minutes, add excess ammonia water at 60-90°C until the pH of the solution is 10.0-12.0, stir at 300-600 rpm, mechanically stir at constant temperature and speed, ...

Embodiment 1

[0036] (1) Weigh 5.56g FeSO 4 ?7H 2 O and 10.58 g FeCl 3 ?6H 2 O, dissolved in 200.0mL ultrapure water, ultrasonically dispersed for 5.0 minutes, heated to 60°C, stirring at 300 rpm, adding excess ammonia water until the pH was -11.0, reacting at constant temperature and speed for 1.0 hours, magnetic separation, successively Washing with ultra-pure water and ethanol for several times until the pH is 6-8, and drying in vacuum at 60°C for 12 hours to prepare nanometer ferric oxide particles.

[0037] (2) Weigh 2.0 g of the nano-iron ferric oxide particles prepared in step (1), and add it to 200.0 mL of ethanol solution, ultrasonically disperse for 5.0 minutes, and stir the reaction at a constant temperature of 60 ° C at a stirring speed of 300 rpm Minutes, 20.0mL oleic acid was added dropwise at a constant speed within 10 minutes, and after 1.0 hours of reaction, magnetically separated, washed with ethanol several times until the pH was 6-8, and vacuum-dried at 60°C for 12 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com