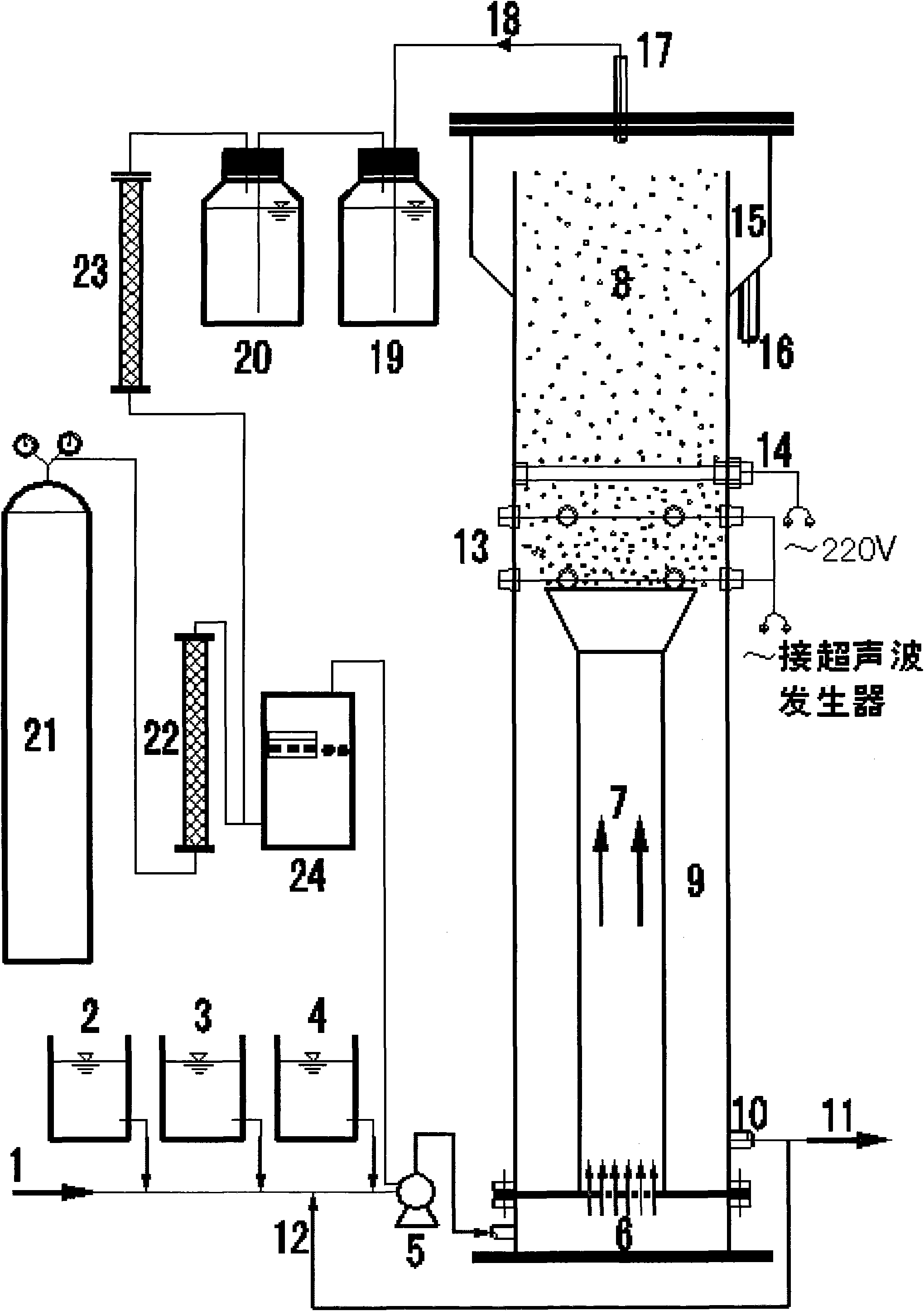

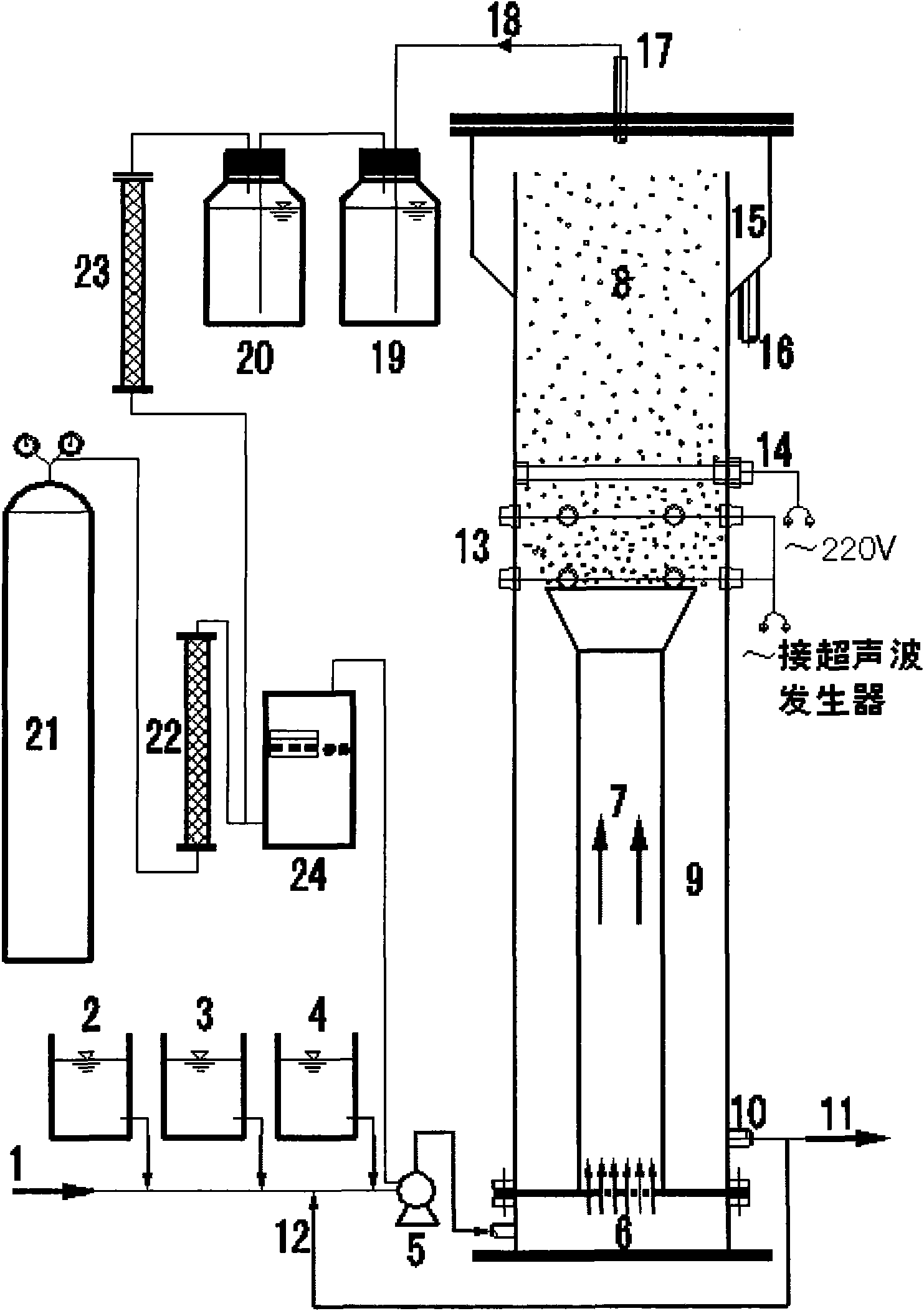

Novel multi-technology synergetic catalysis advanced micro-bubble ozone oxidation tower

A technology of synergistic catalysis and ozone oxidation, applied in the fields of oxidized water/sewage treatment, flotation water/sewage treatment, light water/sewage treatment, etc. Complex ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0019] Using the above-mentioned embodiment as an advanced treatment unit to treat the effluent from the third sedimentation tank of a dry-process acrylic fiber factory in Northeast China, the full analysis shows that the refractory nitriles, nitrogen-containing heterocycles, alkanes and amino organic compounds in the effluent account for more than 86%. . The size of the reactor is: D15cm×H 95em, the total effective volume is 23.7L, the reflux ratio is 100-200%, the dosage of ozone is 1.75g / L, the ultrasonic power is 300W, and the ultraviolet radiation wavelength is UV 254 , The reaction time is 30min. Influent COD Cr 270~310mg / L, UV 254 / US / H 2 o 2 Combination technology synergistically catalyzes O 3 The effluent COD of the oxidation tower is 100-130mg / L, and the average removal rate of COD is 58-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com