Irradiation-resistant, halogen-free and flame-retardant ethylene-propylene cable material and preparation method thereof

A radiation-resistant and cable material technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of increasing the difficulty of fire escape and rescue, affecting cable transmission performance, and weak radiation resistance, so as to achieve enhanced insulation and Mechanical strength, improved radiation resistance, and simple preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

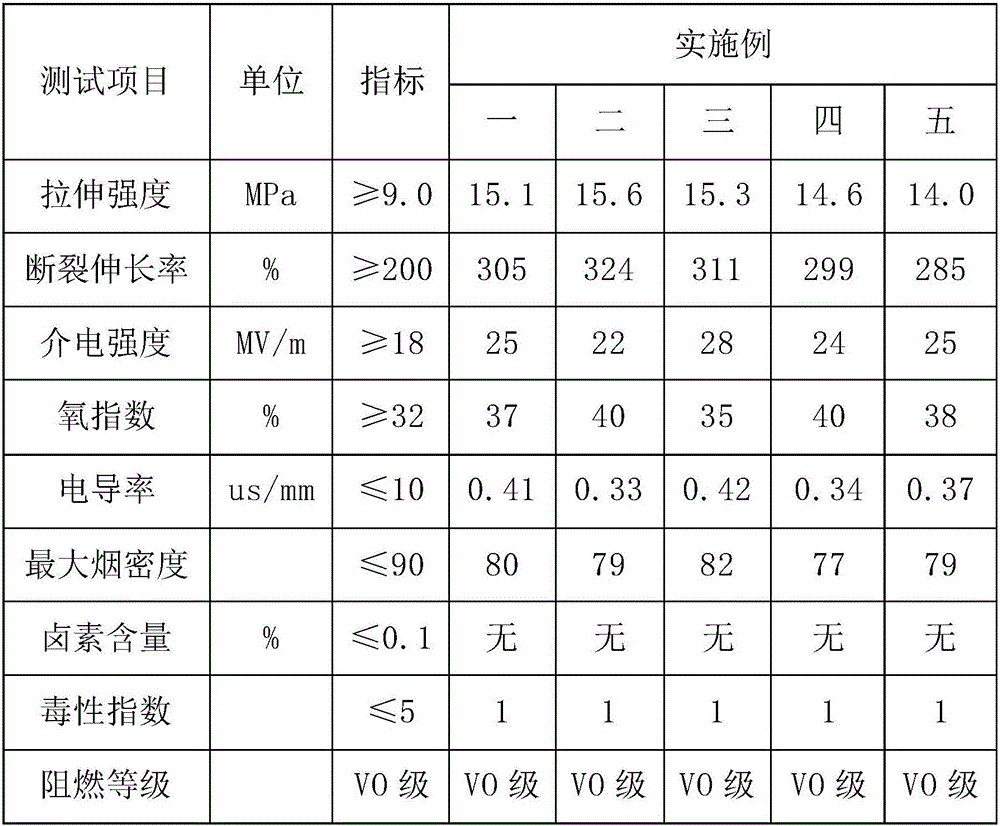

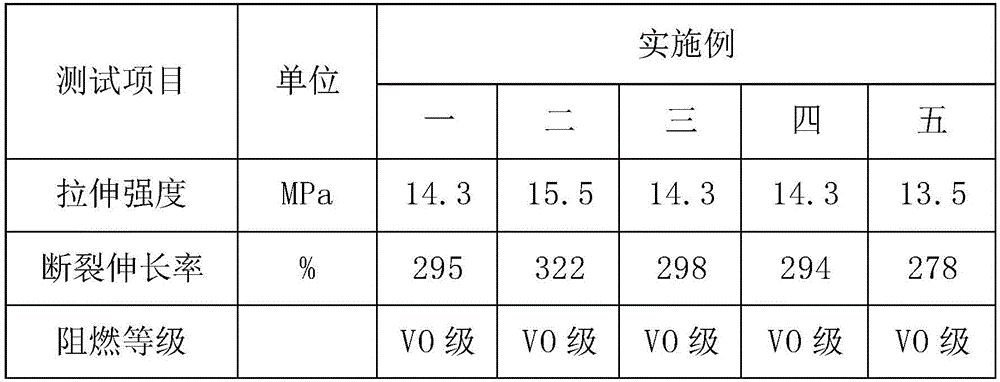

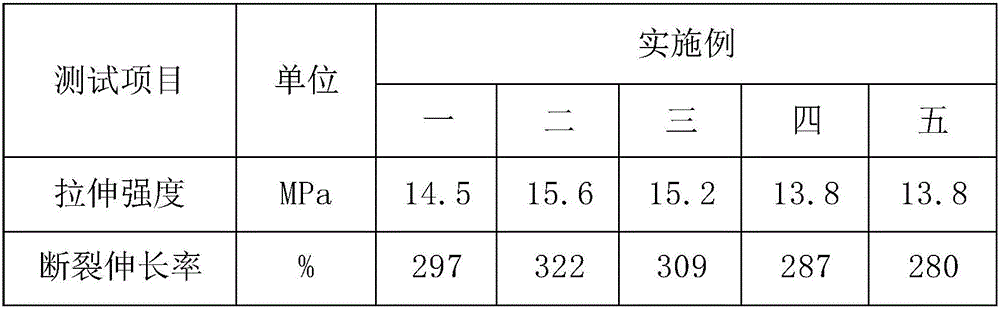

Embodiment 1

[0017] The invention proposes a radiation-resistant halogen-free flame-retardant ethylene-propylene cable material, comprising the following raw materials in parts by weight: 70 parts of polypropylene, 30 parts of ethylene-propylene rubber, 1 part of cumene peroxide, dimethyl dithio 2 parts of zinc carbamate, 8 parts of aluminum hydroxide, 4 parts of magnesium hydroxide, 5 parts of triphenyl phosphate, 8 parts of p-dibenzyl bisphosphate, 7 parts of metal fiber, 5 parts of silver fiber, 10 parts of glass fiber, 3 parts of 2-hydroxy-4-octyloxy benzophenone, 11 parts of dioctyl phthalate, 5 parts of chlorinated paraffin, 1 part of antioxidant, 3 parts of crosslinking agent, and 9 parts of coloring agent.

[0018] The preparation method includes the following steps:

[0019] S1: Turn on the power of the internal mixer, set the preheating temperature of the internal mixer to 140℃, turn on the heating power, after the preheating temperature is reached, keep the temperature and add polypr...

Embodiment 2

[0023] The invention proposes a radiation-resistant halogen-free flame-retardant ethylene-propylene cable material, comprising the following raw materials in parts by weight: polypropylene 40 parts, ethylene-propylene rubber 40 parts, cumene peroxide 0.5 parts, dimethyl dithio 1 part of zinc carbamate, 10 parts of aluminum hydroxide, 6 parts of magnesium hydroxide, 8 parts of triphenyl phosphate, 12 parts of p-dibenzyl bisphosphate, 10 parts of metal fiber, 8 parts of silver fiber, 12 parts of glass fiber, 4 parts of 2-hydroxy-4-octoxy benzophenone, 10 parts of dioctyl phthalate, 3 parts of chlorinated paraffin, 0.5 part of antioxidant, 3 parts of crosslinking agent, 8 parts of coloring agent.

[0024] The preparation method includes the following steps:

[0025] S1: Turn on the power of the internal mixer, set the preheating temperature of the internal mixer to 150°C, turn on the heating power, after the preheating temperature is reached, keep the temperature and add polypropylene...

Embodiment 3

[0029] The radiation-resistant halogen-free flame-retardant ethylene-propylene cable material proposed by the present invention includes the following raw materials in parts by weight: 80 parts of polypropylene, 20 parts of ethylene-propylene rubber, 1 part of cumene peroxide, and dimethyl dithio 2 parts of zinc carbamate, 5 parts of aluminum hydroxide, 3 parts of magnesium hydroxide, 2 parts of triphenyl phosphate, 6 parts of p-dibenzyl bisphosphate, 10 parts of metal fiber, 5 parts of silver fiber, 11 parts of glass fiber, 1 part of 2-hydroxy-4-octoxy benzophenone, 12 parts of bis(2-ethylhexyl) phthalate, 5 parts of chlorinated paraffin, 1 part of antioxidant, 1 part of crosslinking agent, coloring 6 parts.

[0030] The preparation method includes the following steps:

[0031] S1: Turn on the power of the internal mixer, set the preheating temperature of the internal mixer to 130°C, turn on the heating power, after the preheating temperature is reached, keep the temperature and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com