Flotation separation inhibitor and separation method of galena, pyrite and sphalerite

A separation method, pyrite technology, applied in flotation, solid separation, etc., can solve the problems of poor concentrate quality, entrained impurities, blockage of pipelines, etc., and achieve high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A high-sulfur complex refractory lead-zinc mine in Guangdong. The main metal minerals in the ore are pyrite, sphalerite and galena. The main gangue minerals are quartz, calcite, feldspar and so on. The results of the multi-element analysis of the raw ore are shown in Table 1.

[0016] Table 1 The results of multi-element chemical analysis of samples / %

[0017] element Zn Pb Cu TF SiO 2 Al 2 o 3 CaO content 8.50 4.30 0.07 25.3 12.81 0.74 5.20 content MgO Na 2 o K 2 o As S Au (g / t) Ag (g / t) content 0.55 0.96 0.78 0.19 28.10 <0.1

89.16

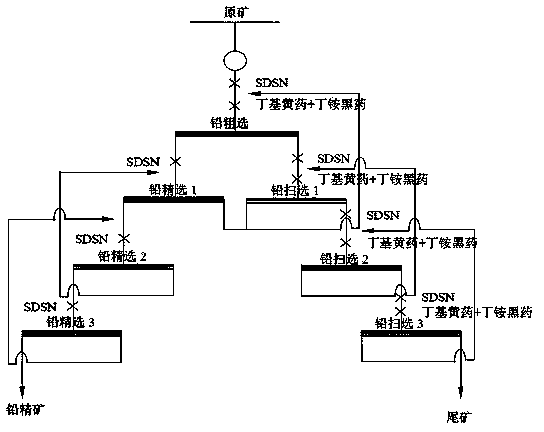

[0018] process such as figure 1 As shown, the specific process parameters are as follows:

[0019] (1) Grinding: 85% of the raw ore is ground to a particle size of less than 200 mesh;

[0020] (2) Lead flotation: After grinding, the ore slurry is subjected to lead flotation. The flotation process is a lead roughing, three lead refining and a lead sweep...

Embodiment 2

[0024] A high-sulfur lead-zinc mine in Hunan, the main metal minerals in the ore are pyrite, galena and sphalerite. The main gangue minerals are dolomite, calcite, quartz and so on. The results of the multi-element analysis of the raw ore are shown in Table 2.

[0025] Table 2 The results of multi-element chemical analysis of samples / %

[0026] element TF Cu Pb Zn S As mn content 11.44 0.054 3.55 4.15 16.50 0.28 0.36 content CaO MgO SiO 2 al 2 o 3 CaF 2 Au (g / t) Ag (g / t) content 29.25 1.75 20.23 3.21 0.47 1.10 150.50

[0027] process such as figure 1 As shown, the specific process parameters are as follows:

[0028] (1) Grinding: 70% of the raw ore is ground to a particle size of less than 200 mesh;

[0029] (2) Lead flotation: After grinding, the ore slurry is subjected to lead flotation. The flotation process is a lead roughing, three lead refining and a lead sweeping to obtain lead concentrate. ...

example 3

[0032] A lead-zinc mine in Vietnam, the main metal minerals in the ore are pyrite, sphalerite and galena. The main gangue minerals are quartz, calcite, dolomite and so on. The results of the multi-element analysis of the raw ore are shown in Table 3.

[0033] Table 3 The results of multi-element chemical analysis of samples / %

[0034] element Pb Zn Cu SiO2 Al2O3 CaO MgO content 1.85 0.73 0.02 35.93 10.80 12.02 6.74 content S Fe CaF 2 K 2 o Na 2 o Au (g / t) Ag (g / t) content 7.13 6.78 0.14 2.54 1.38 <0.1

80

[0035] process such as figure 1 As shown, the specific process parameters are as follows:

[0036] (1) Grinding: Raw ore is ground to a particle size of less than 200 mesh, accounting for 76%;

[0037] (2 Lead flotation: lead flotation is performed on the pulp after grinding. The flotation process is one lead roughing, two lead selections and two lead sweeps to obtain lead concentrate. In the lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com