Large industrial system feedback data real-time processing method and system based on Web

A technology of real-time processing and feedback data, which is applied in the direction of electrical digital data processing, special data processing applications, structured data retrieval, etc., can solve the problems of high data acquisition cost, low real-time performance, slow data storage efficiency, etc., and achieve scalability High, improve user experience, good openness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

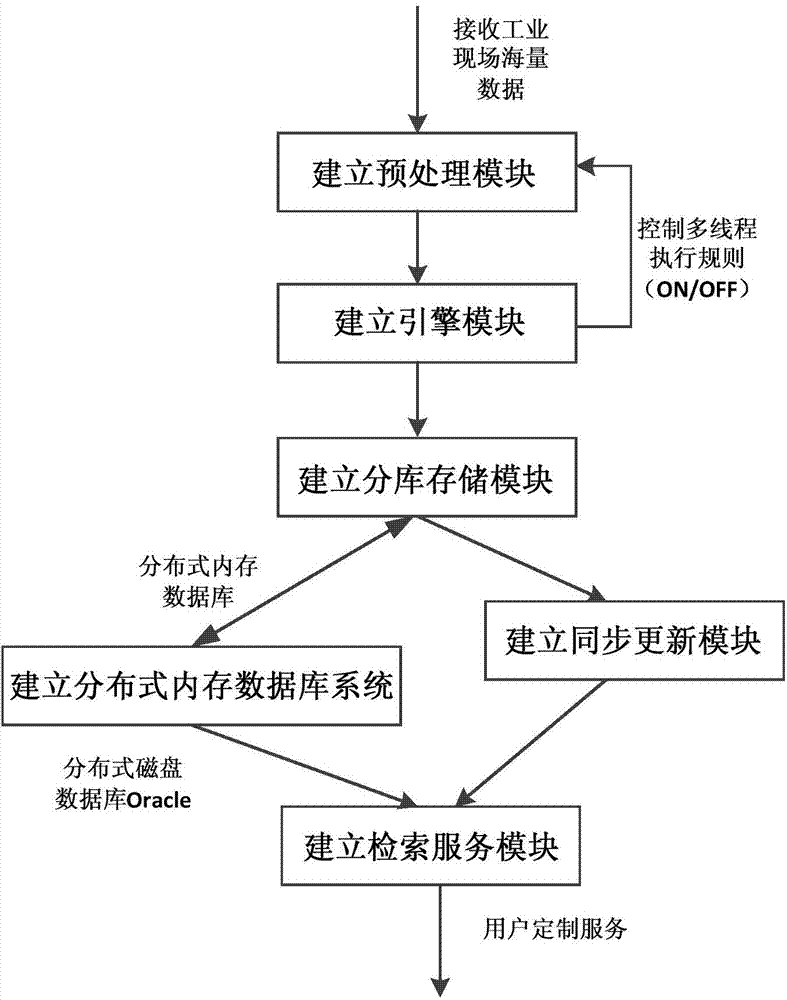

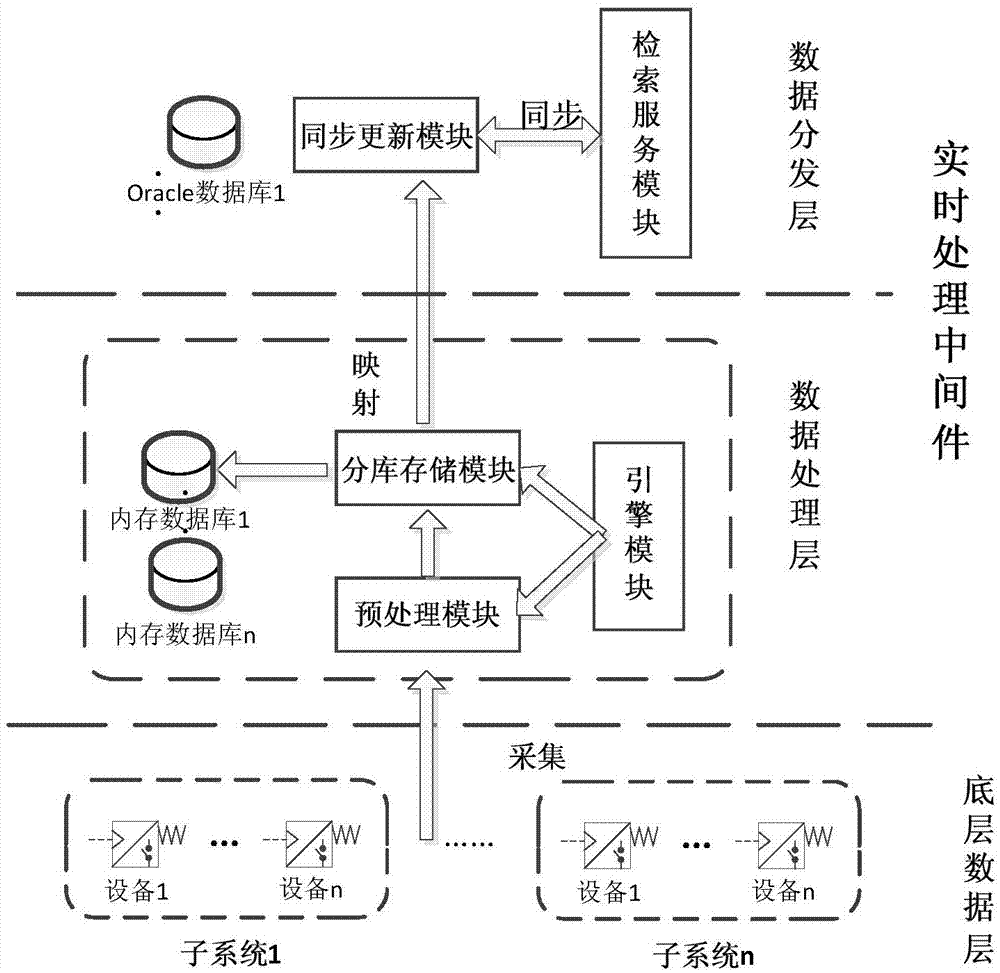

[0049] figure 1 Is a logical architecture diagram of the real-time processing middleware provided by the embodiment of the present invention; figure 2 The system architecture diagram of a Web-based large-scale industrial system feedback data real-time processing platform provided by an embodiment of the present invention is shown in the figure: The Web-based large-scale industrial system feedback data real-time processing method provided by the present invention includes the following steps:

[0050] S1: Establish the underlying data layer for collecting industrial system raw data of industrial field equipment;

[0051] S2: Establish a data processing layer for distributed data processing of the industrial system raw data collected in the underlying data layer, and establish a time stamp for real-time data access and historical data retrieval optimization;

[0052] S3: Establish a data distribution layer for dynamic paging storage of the raw data of the industrial system, and establ...

Embodiment 2

[0085] The process and system structure of the method and system structure for real-time processing of feedback data of a large-scale industrial system based on Web described in detail in Embodiment 2 of the present invention.

[0086] The establishment steps of the method for real-time processing of feedback data of a large-scale industrial system based on Web provided in this embodiment are as follows:

[0087] Through real-time collection of massive bottom-level data of different equipment units distributed in different subsystems in a large industrial system, and then through the data preprocessing layer to filter the massive data, provide the memory database while establishing a time stamp for real-time Data access and historical data retrieval are optimized, and finally the filtered data is dynamically stored in data pages at the data distribution layer to ensure real-time data and provide efficient historical data retrieval strategies. This series of operations are synchroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com