Fault diagnosis method, device and equipment for industrial system and storage medium

An industrial system and fault diagnosis technology, applied in the field of fault diagnosis, can solve problems such as difficult application of multi-sampling rate systems, and achieve the effects of wide application range, improved convergence speed and quality, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes to further explain the technical solution of the present invention.

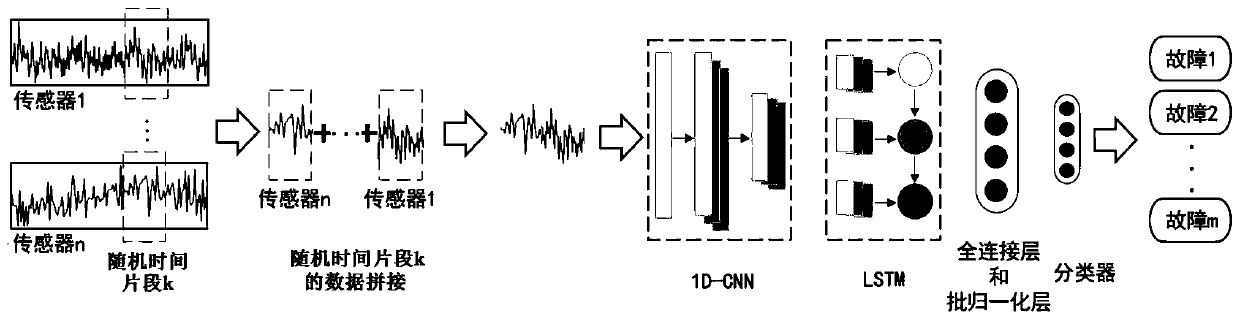

[0037] The invention provides a fault diagnosis method for an industrial system based on multi-sampling rate sensor data fusion, such as figure 1 shown, including:

[0038] 1. Construct a training sample set

[0039] Obtain the historical original sequence output by multiple sensors preset in the industrial system and the corresponding industrial system fault types; for each fault type, N time segments with a time span of T are randomly selected from the historical original sequence, and different sensors The data in the same time segment are spliced sequentially, and the reconstructed sequence obtained by splicing is normalized to obtain the preproce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com