Basic automation-based plant-level equipment management and alarming system and method

A basic automation and equipment management technology, applied in the field of equipment maintenance and management, can solve the problems that affect the accuracy of fault judgment and the timeliness of troubleshooting, the management area of the maintenance personnel of the operation station is not the same, and the operators cannot be caused in time, etc., to achieve a high degree of system Integrate, eliminate the interference of human factors, and facilitate centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

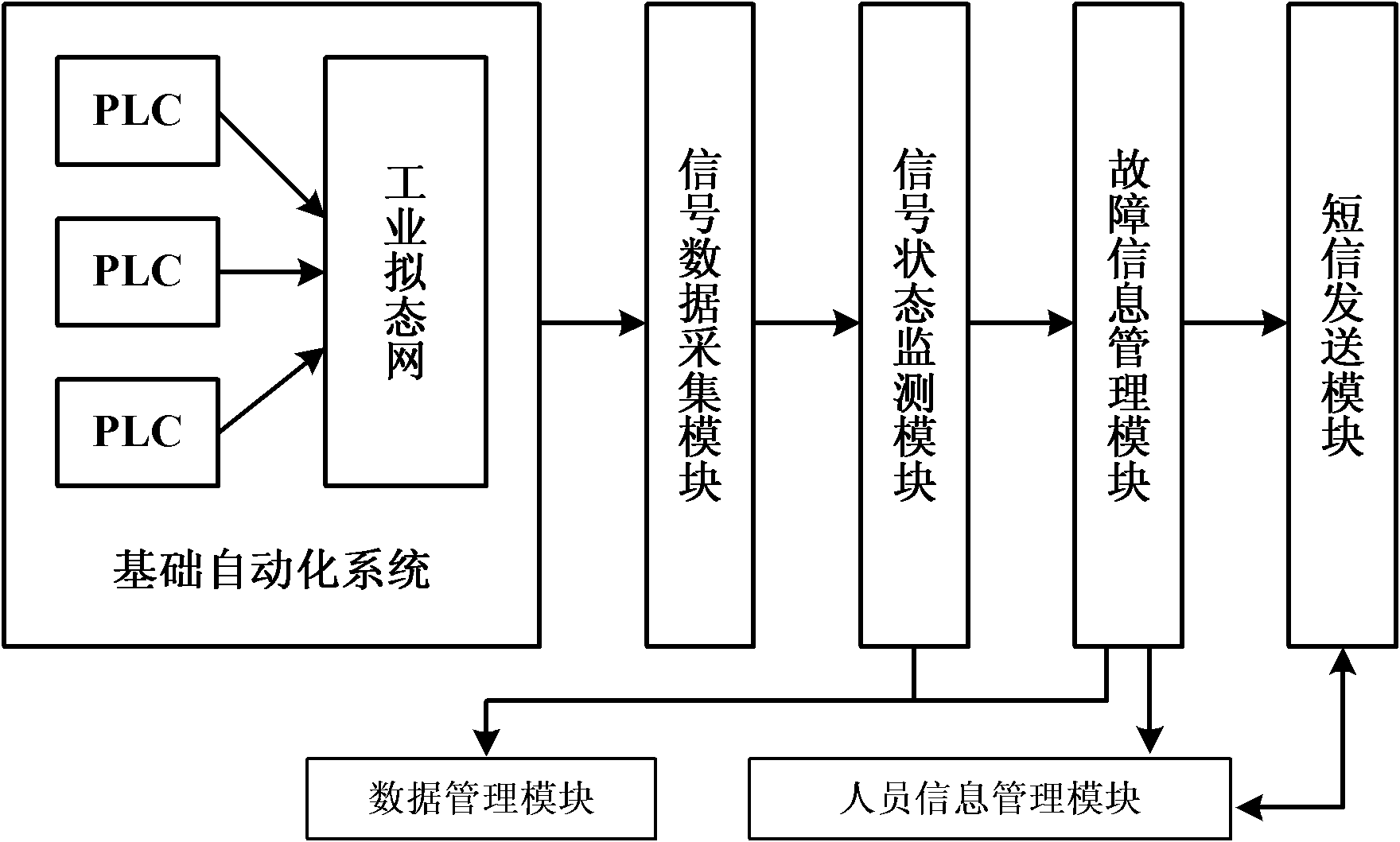

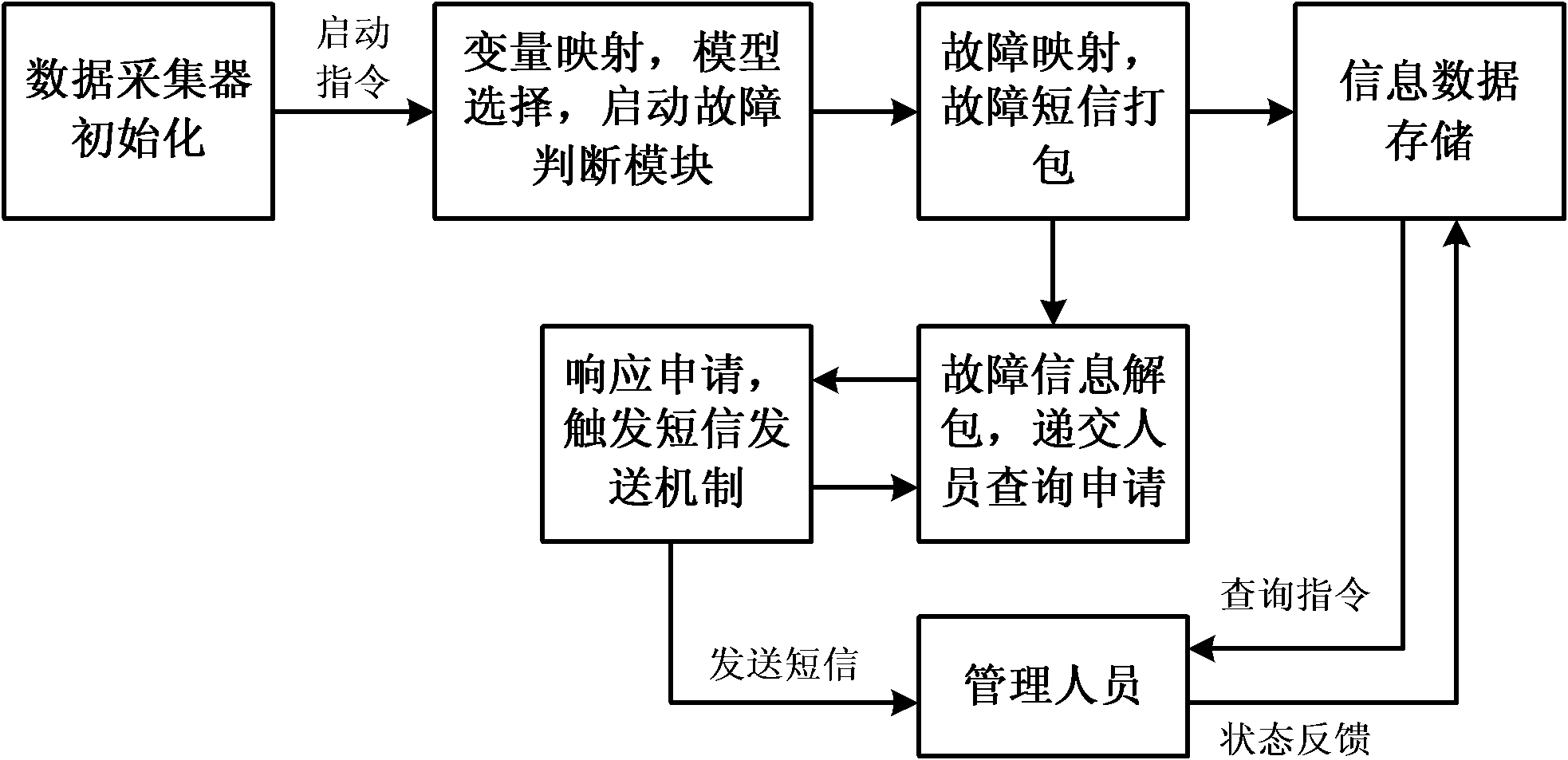

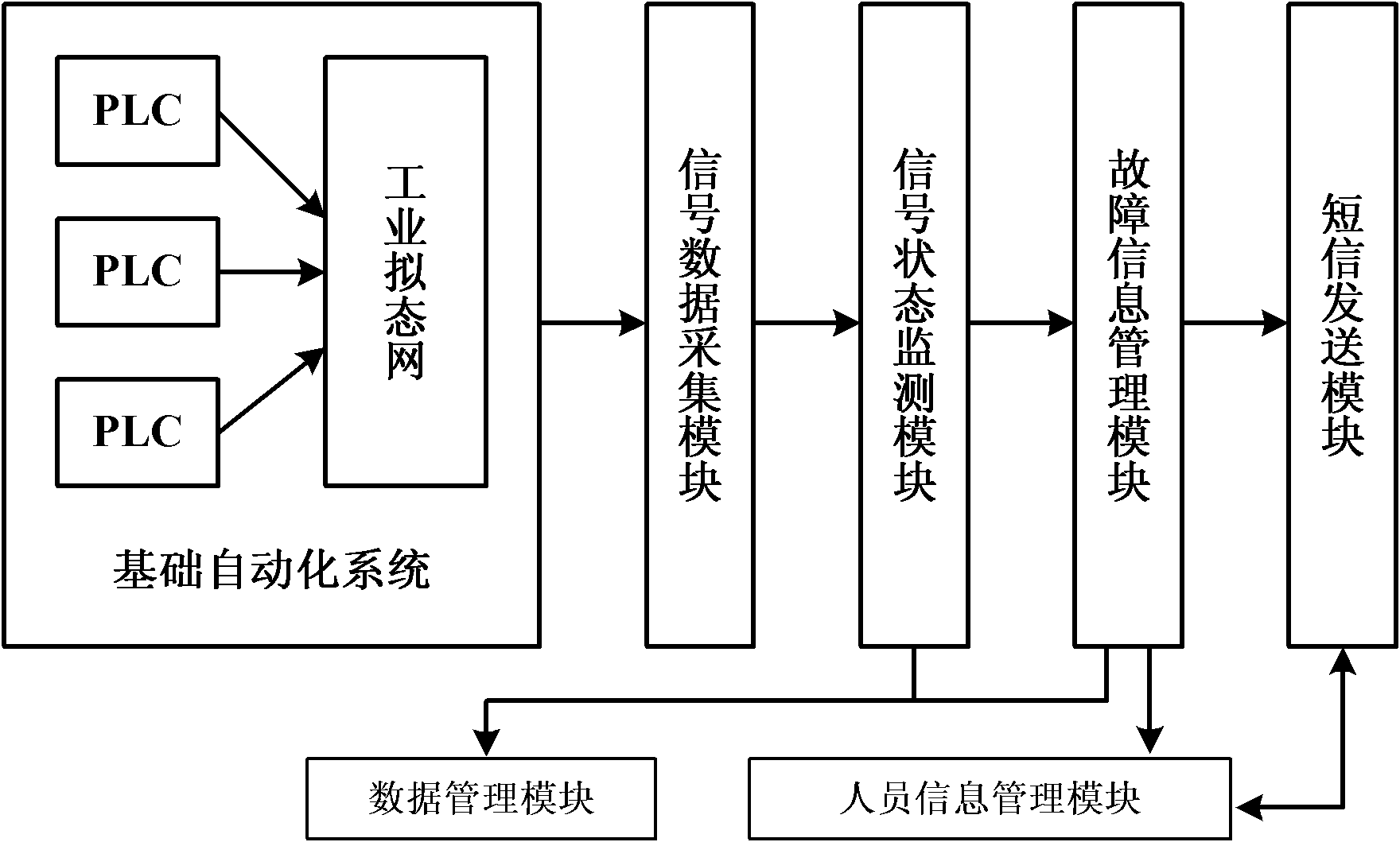

[0064] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment:

[0065] The present invention provides on-line monitoring and analysis of the maintenance data of the basic automation control system and various equipment for equipment maintenance and management personnel, which is independent of the operation station and the engineer station, and provides short message early warning and alarm for equipment and system failures in time. Record the handling measures and structure of equipment and system failures, provide analysis and recommendation reports for equipment repairs and maintenance plans, and provide plant-level equipment management and SMS early warning and alarm systems for equipment and system failures. Through this system, maintenance personnel can inquire and understand the status of the system and equipment in time, grasp the early warning and alarm information of equipment and system failures in re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com