Thermal power plant smoke depth cooler heat return optimization on-line monitoring device and method

A deep cooling and monitoring device technology, applied in lighting and heating equipment, steam generation, control systems, etc., can solve the problems of not being able to realize the deep cooler of flue gas and affecting the economy of the whole plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

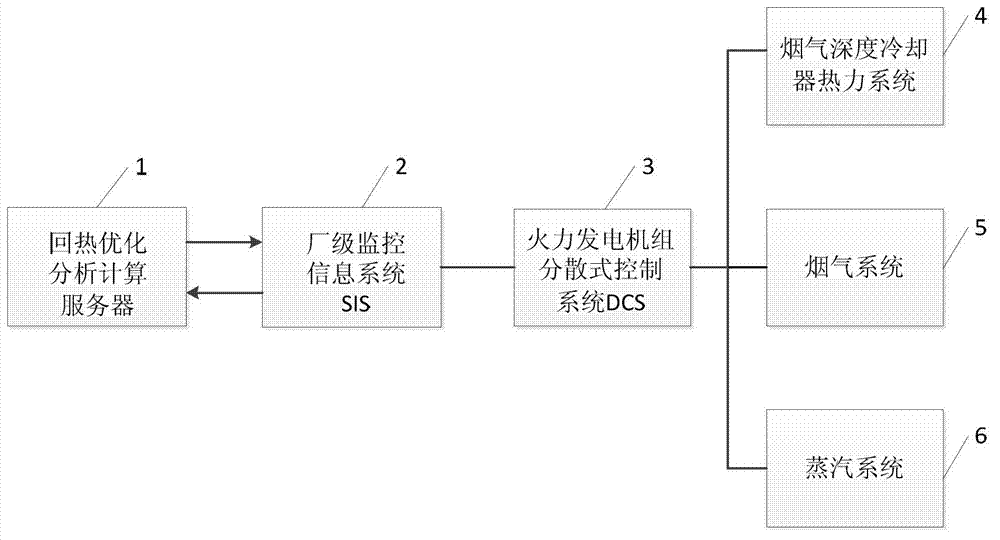

[0064] Such as figure 1 As shown, the present invention is an on-line monitoring device for heat recovery optimization of a thermal power plant flue gas deep cooler, including a heat recovery optimization analysis calculation server 1, a plant-level monitoring information system SIS2, and a thermal power generation unit distributed control system DCS3. The unit distributed control system DCS3 includes a flue gas deep cooler thermal system 4 , a flue gas system 5 and a steam system 6 .

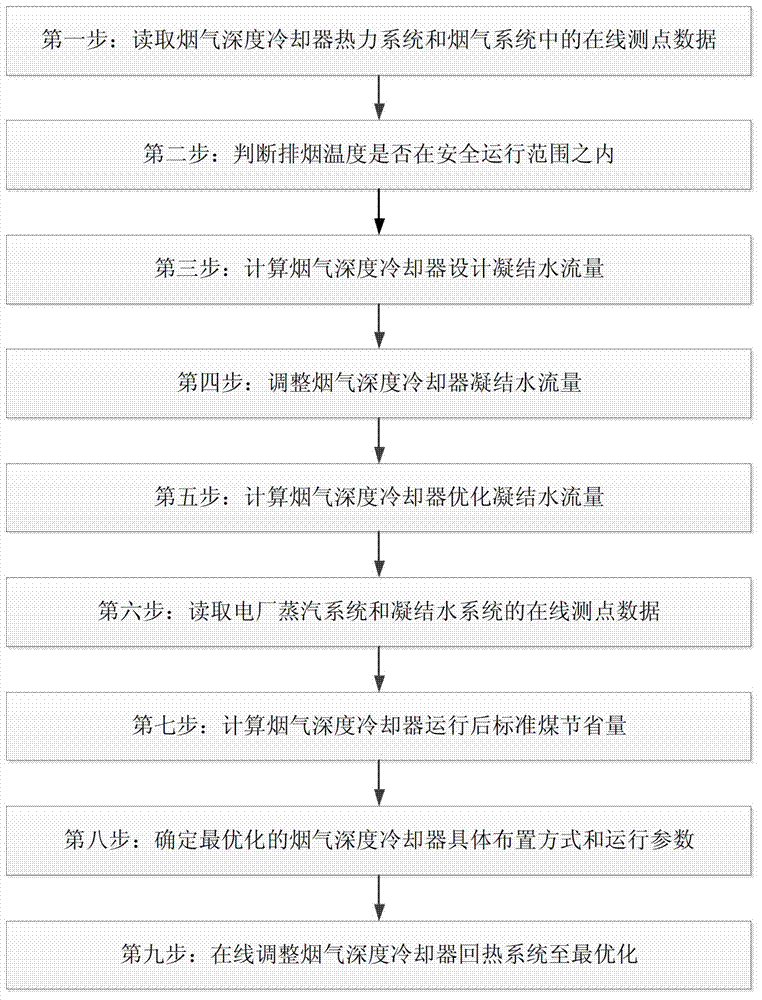

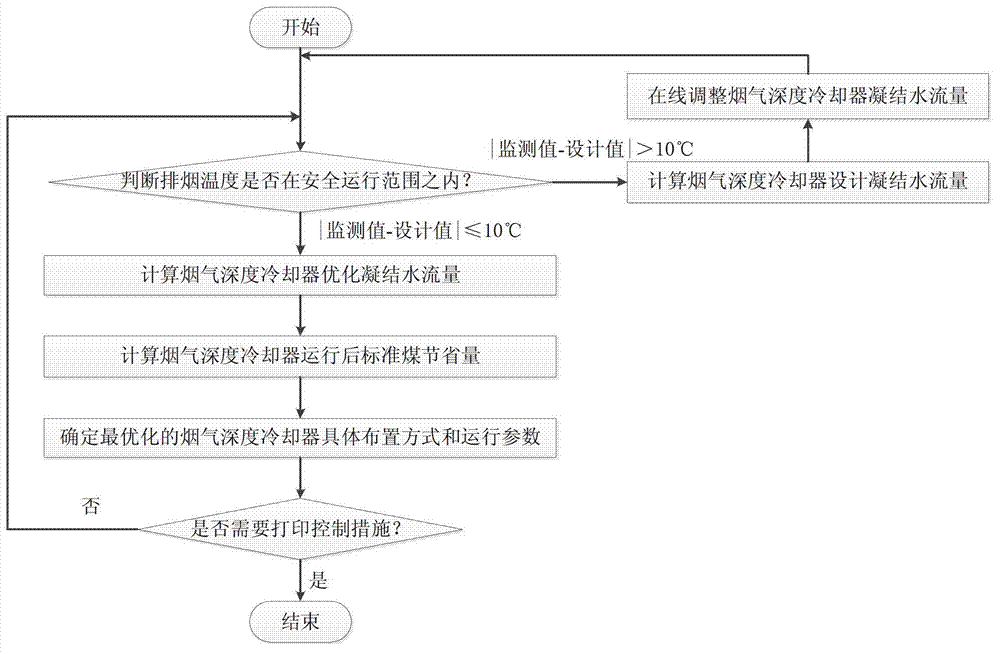

[0065] For a certain type of 300MW power plant boiler, the layout and operating parameters of the designed flue gas deep cooler are as follows: parallel connection with 6# low-pressure heater, the water inlet is the outlet of the 7# low-pressure heater, and the water return port is the inlet and outlet of the 5# low-pressure heater The exhaust gas tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com