Method for intelligently managing wall temperature of final superheater and final reheater of boiler of power station

A final stage superheater and final reheater technology, applied in lighting and heating equipment, steam generation, control systems, etc., can solve problems affecting the safe operation of boilers, damaged pipes, etc., and achieve fast online real-time calculation and online Effects of monitoring and control and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

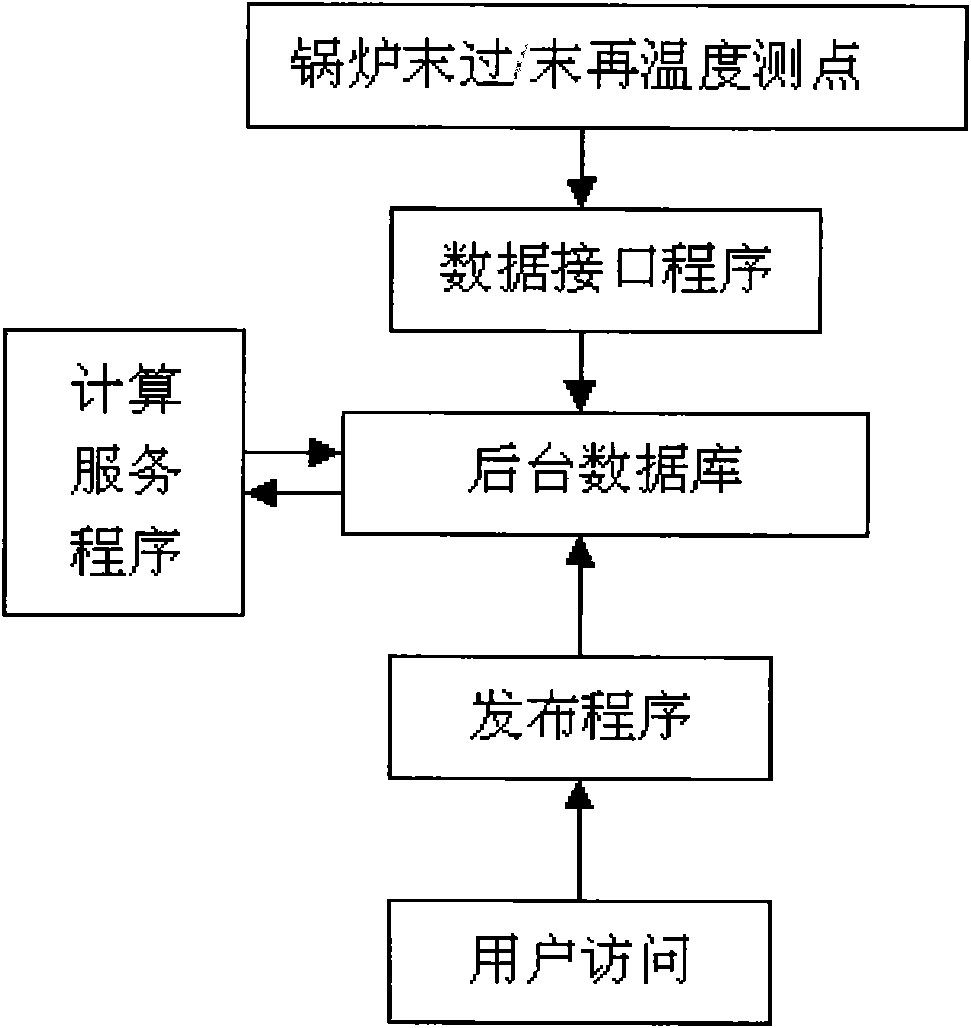

[0029] For a supercritical 600MW power plant boiler in a power plant, the final superheater and final reheater adopt figure 1 The intelligent wall temperature management system shown. Its main components are: computing server, database server, web server, and plant-level monitoring information system (PI system). The web server is respectively connected with the client browser, the database server and the calculation server, the database server is connected with the calculation server, and the database server is connected with the power plant DCS system or MIS system and online measuring points through the plant-level monitoring information system.

[0030] Method provided by the invention comprises the following steps:

[0031] Step 1: Read the online monitoring data of the boiler final stage superheater and final stage reheater in the PI database, and save it in the local relational database.

[0032] The data interface service program regularly triggers the process every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com