Optimal distribution method and system for heat-engine plant plant-level loads

A technology of plant-level load and distribution method, applied in the direction of single-network parallel feeding arrangement, etc., can solve the problems of insignificant energy saving effect, not taking into account the differences of each unit, avoiding frequent reciprocating adjustment, and always saving energy. The effect of low consumption and reduction of life loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

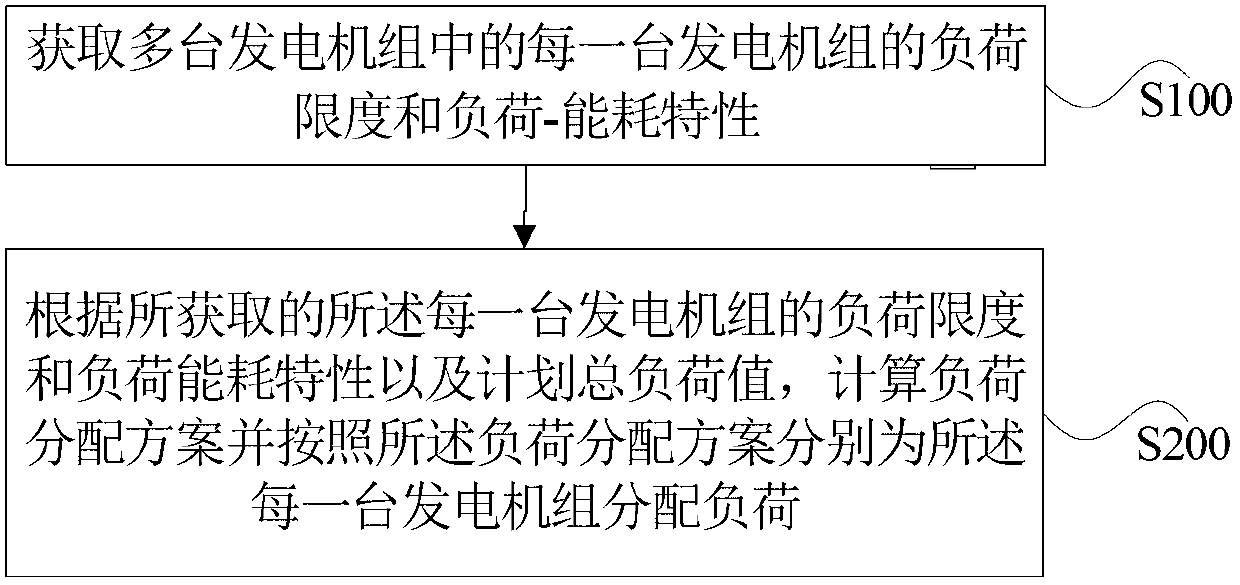

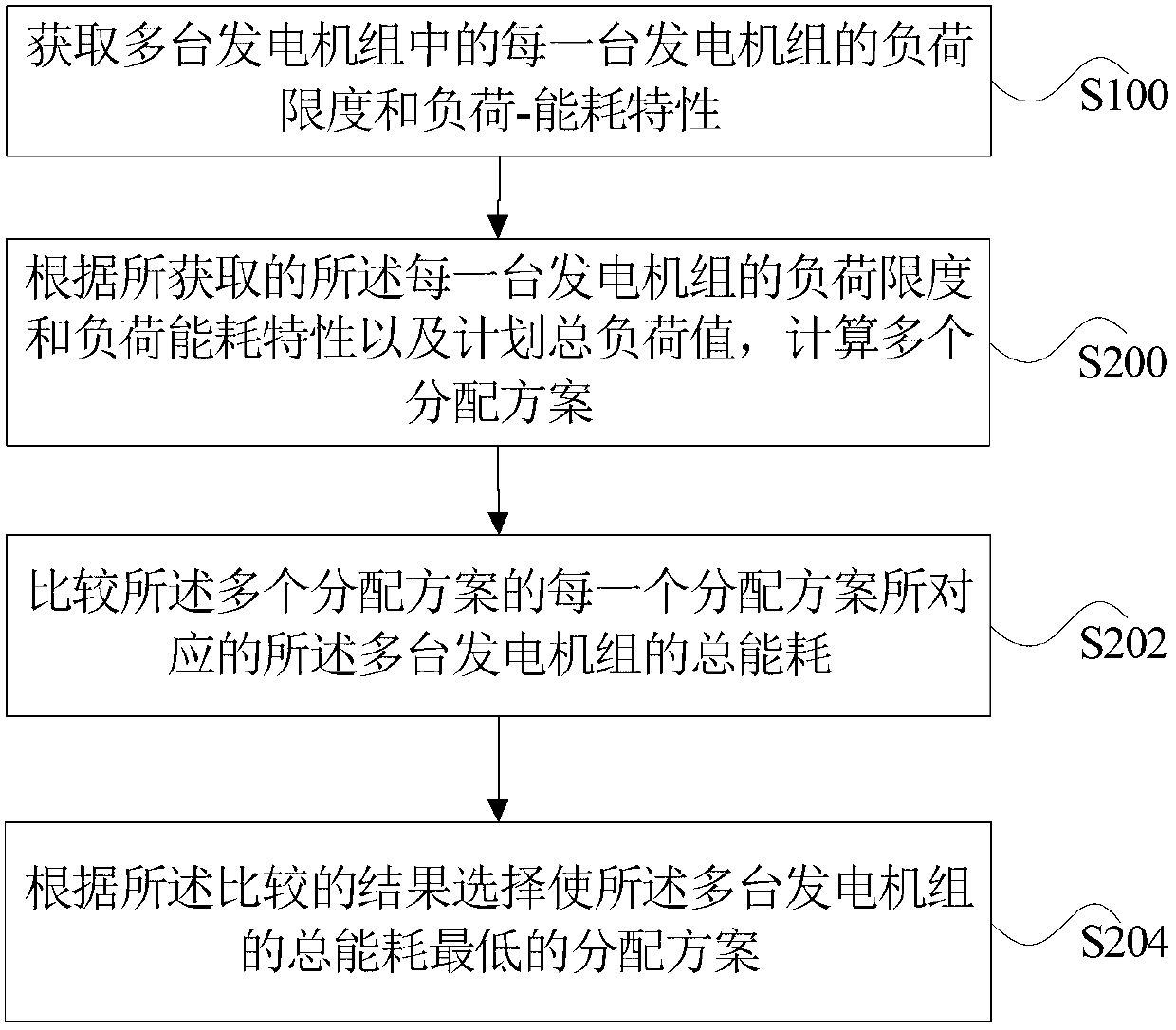

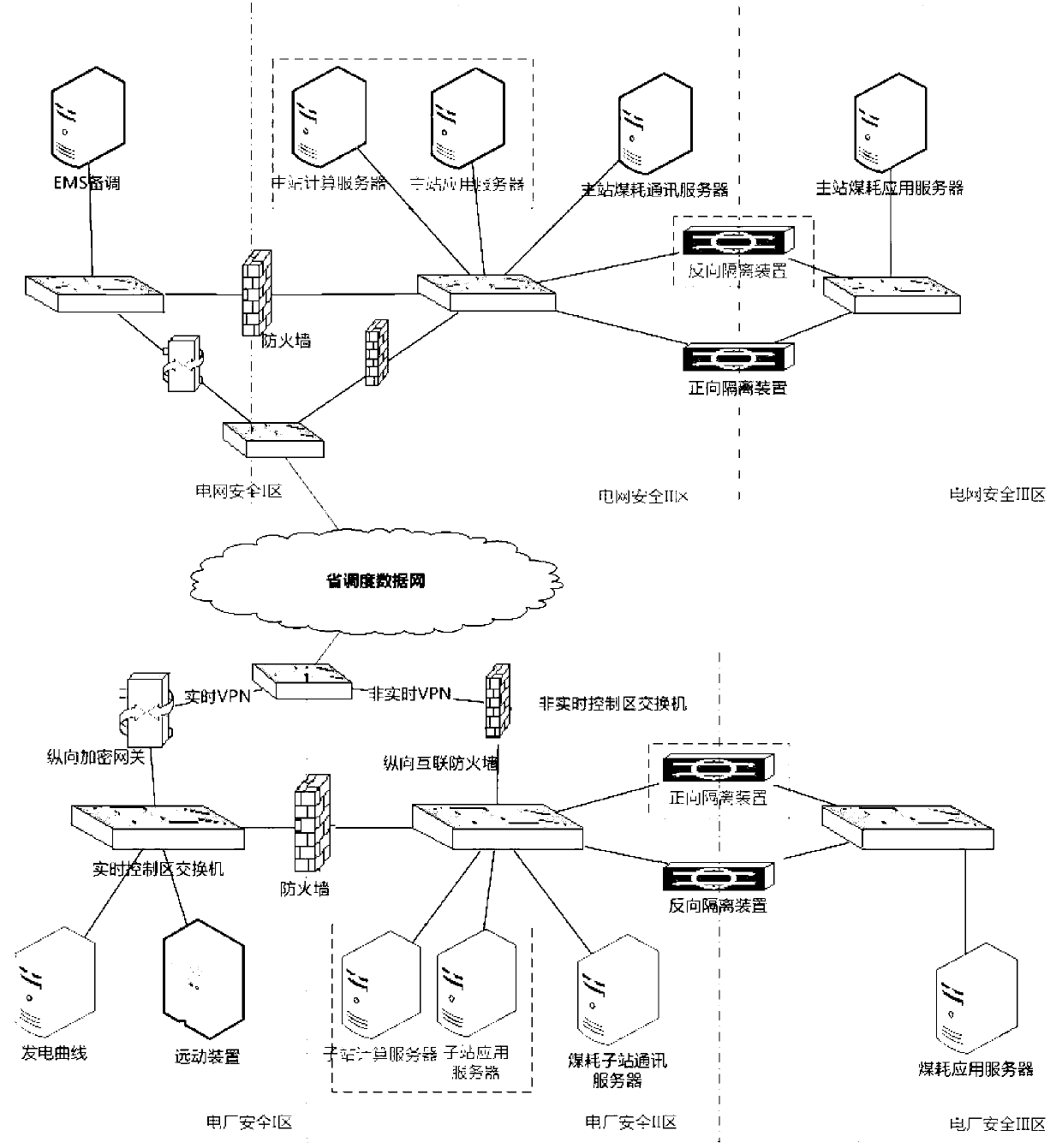

[0022] From the introduction of the background technology, it can be seen that the plant-level load dispatching of thermal power plants in the prior art adopts the AGC dispatching method. However, this dispatching method mainly has the following problems: First, the single-unit AGC dispatching load adjustment frequency is too high, the reciprocating adjustment is frequent, the command is over-adjusted, and the actual unit cannot respond, which affects the operating economy and life loss of the unit; secondly, the single-unit AGC AGC dispatching cannot implement load optimization distribution according to unit economic differences. For the entire power grid, due to the large num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com