Selective wear-based equipment optimal maintenance time prediction method

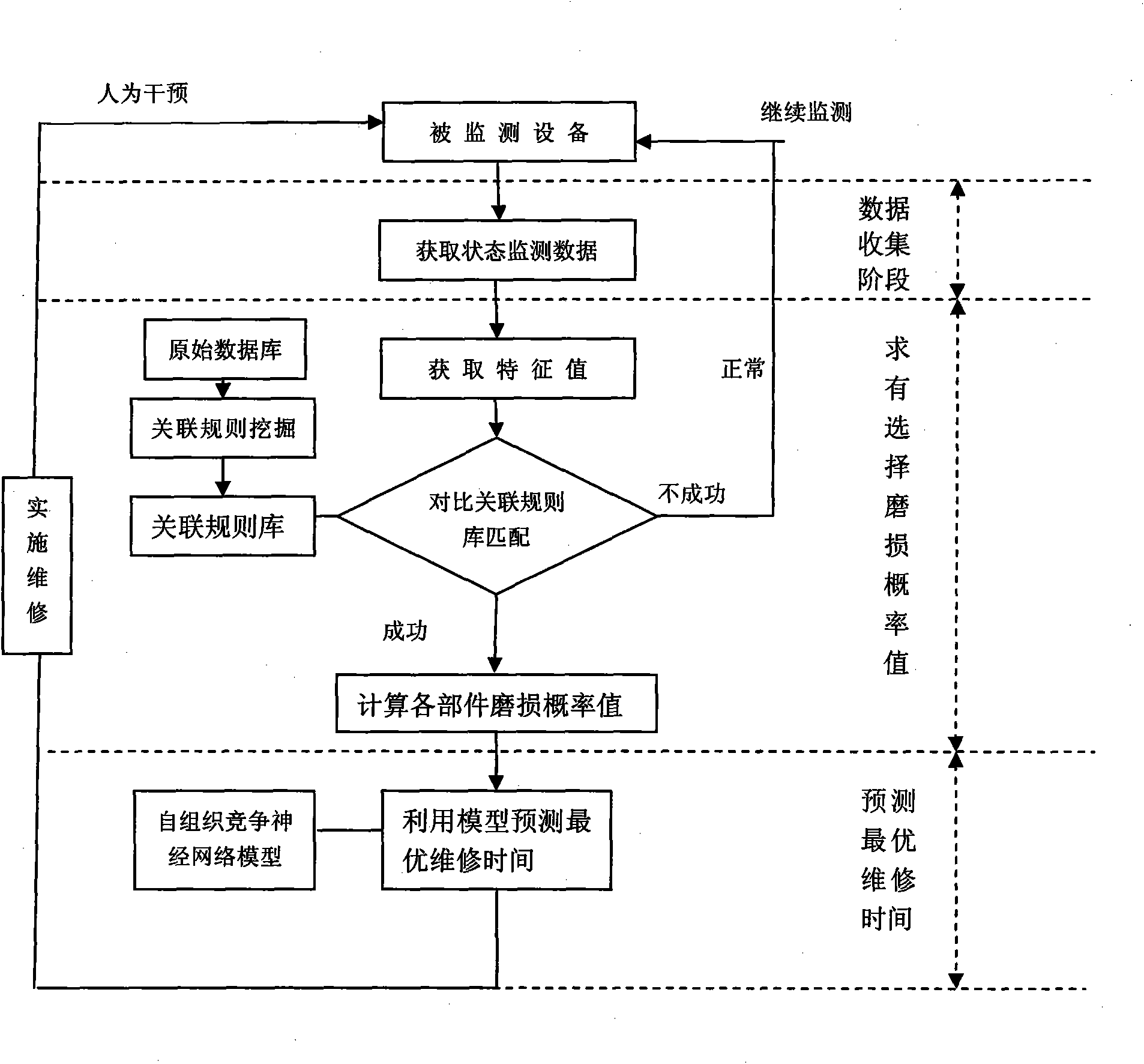

A technology of maintenance time and selectivity, applied in the direction of neural learning methods, special data processing applications, instruments, etc., can solve difficult to deal with various faults, failure to effectively consider the interconnection and influence of equipment, and difficult to obtain predicted values, etc. problem, to achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] A large-scale forging system of a steel company is mainly composed of three equipments A, B, and C. A large amount of previous operation data (including normal state, fault state and fault time) is stored in the database of the system, including sampling on the three equipments. Points: temperature, pressure, vibration, speed and wear level of each component.

[0103] The implementation steps are as follows:

[0104]1) First build an association rule base based on selective attrition, as follows;

[0105] ●Obtain sample data of temperature, pressure, vibration, rotational speed, and wear level of each component from the database, and clean and remove inconsistent data; in order to prevent attributes with larger values from being overweight than attributes with smaller values, normalize the data and then scale the above normalized data to make them all fall on [0, 1], and establish a device monitoring data set.

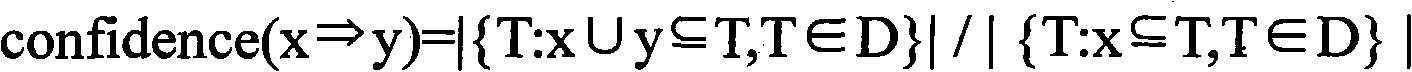

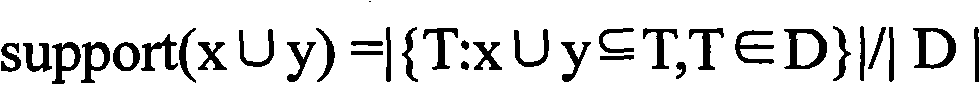

[0106] ●The data table processed by the Apriori algori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com