Container crane

A container crane and container technology, which is applied to the crane, trolley crane, transportation and packaging, etc., can solve the problem of container position deviation, and achieve the effect of suppressing the increase of the number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

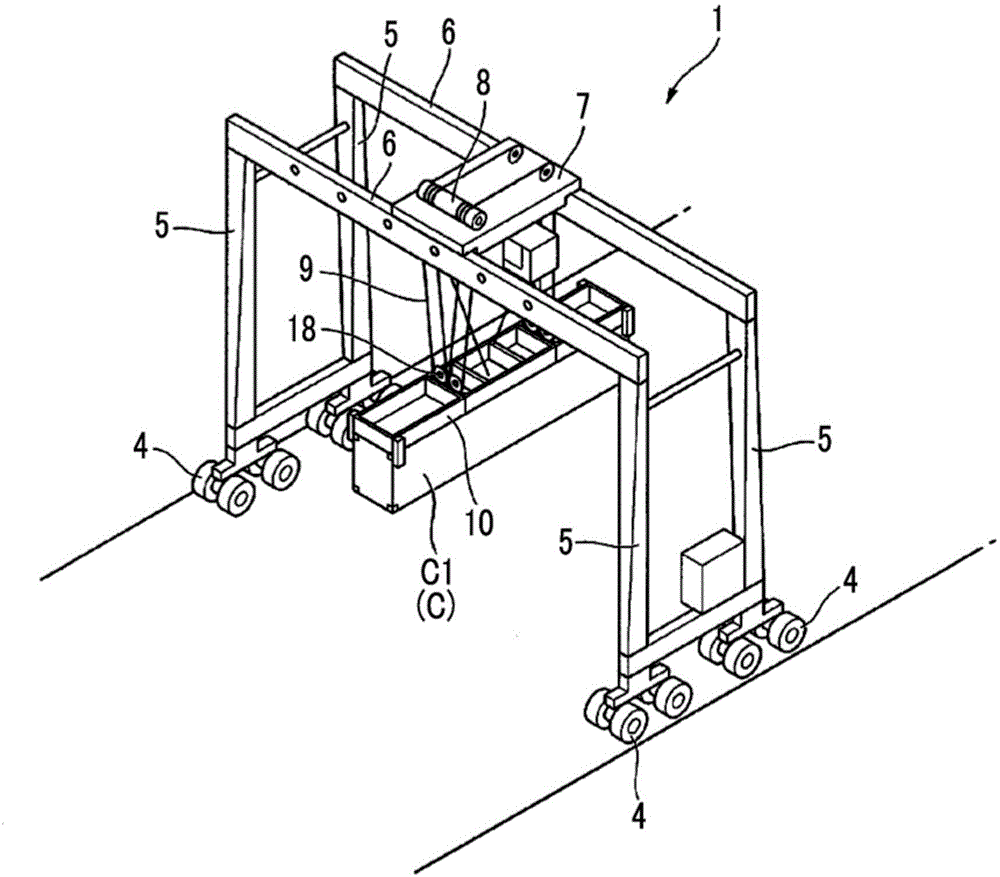

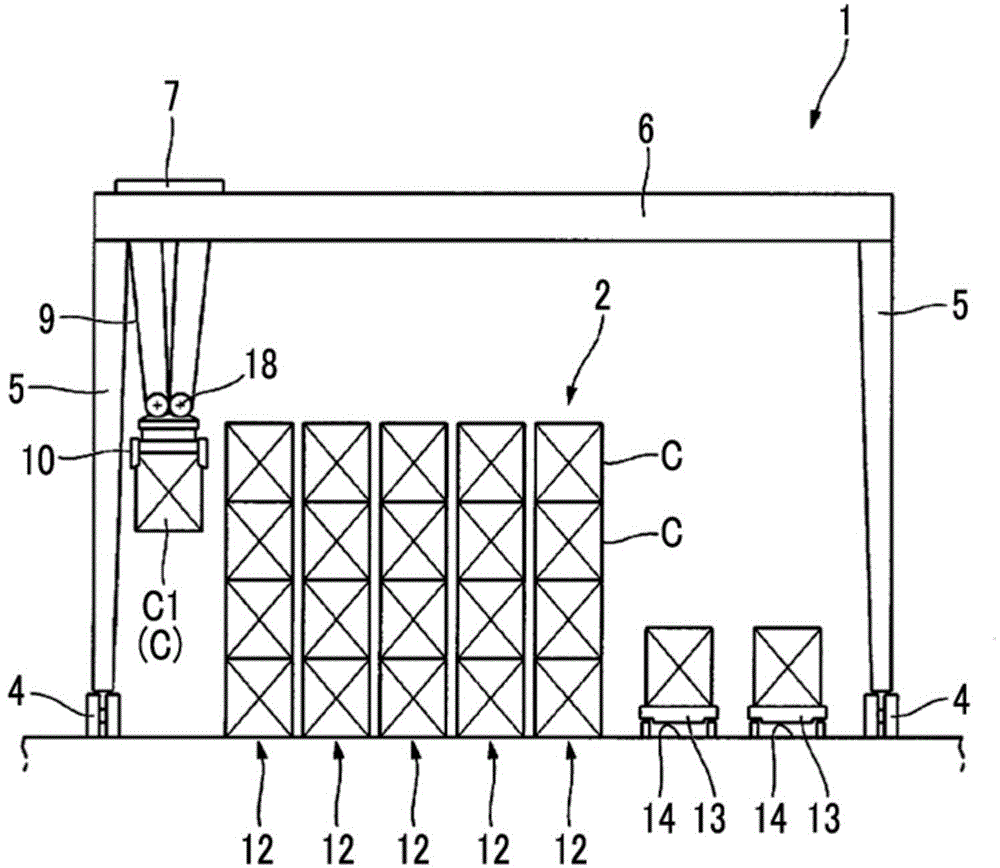

[0045] Next, the container crane in embodiment of this invention is demonstrated based on drawing. The container crane 1 in this embodiment is installed, for example, in a container yard of a container terminal that performs unloading of containers C, loading of containers C, and the like on a container ship calling at the terminal.

[0046] figure 1 , figure 2 It is a figure which shows the schematic structure of the container crane 1 of this embodiment.

[0047] like figure 1 , figure 2 As shown, the container crane 1 is respectively arranged in a plurality of sections 2 provided in a container yard, and loads and unloads a container C. As shown in FIG. The container 1 is made self-propellable by a running device 4 having wheels with tires. The container 1 is formed in a substantially door shape including two pairs of legs 5 supported by the traveling gear 4 and a crane girder 6 connecting upper ends of the legs 5 . Furthermore, the container crane 1 includes a troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com