Container-truck positioning system and method for container crane

A technology of container cranes and trucks, which is applied in the field of truck alignment, can solve the problems affecting the productivity of container automation terminal operations, and achieve the effect of improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

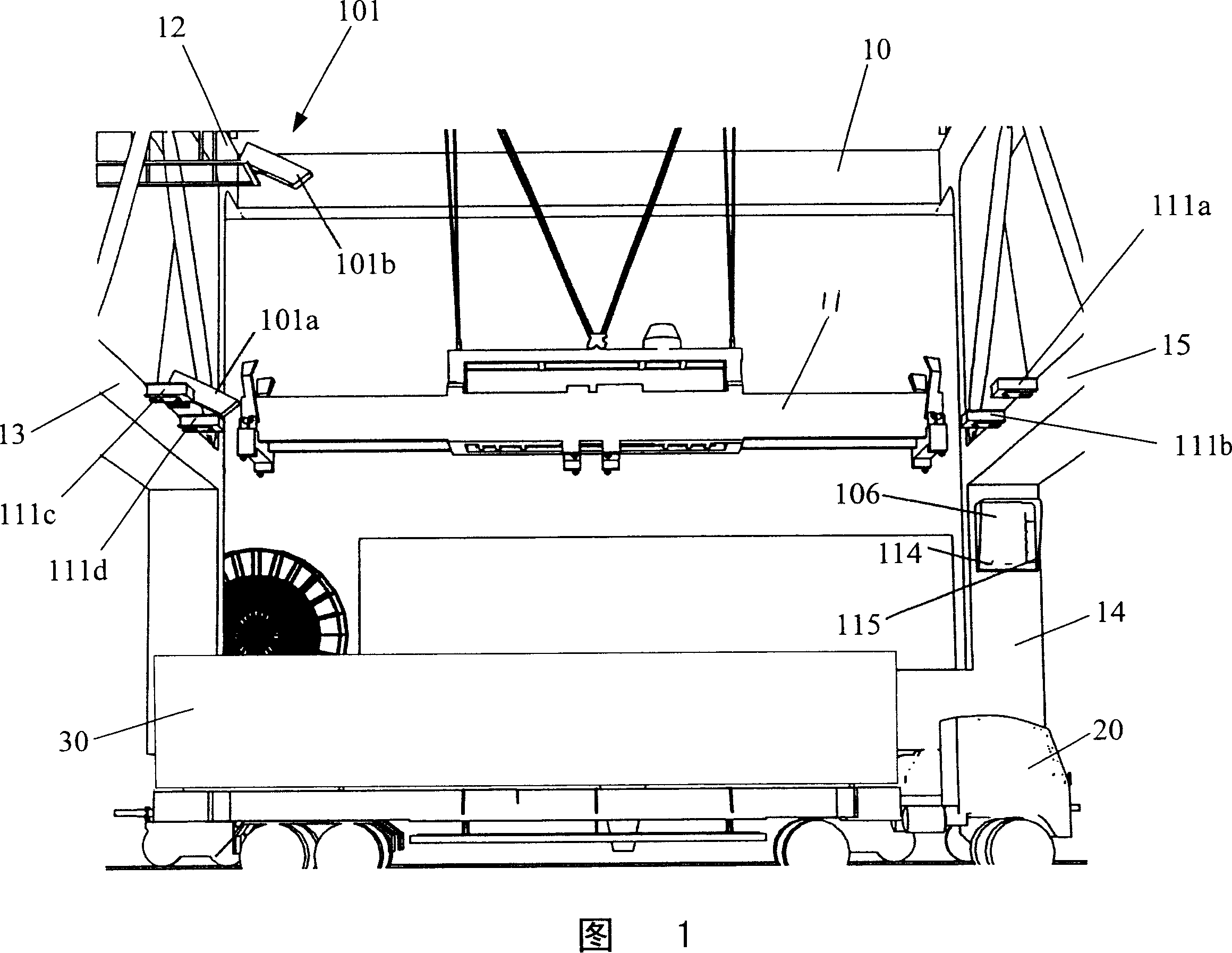

[0054] FIG. 1 is a layout diagram of the truck alignment system of the container crane of the present invention. As shown in FIG. 1 , a truck 20 is parked at the loading and unloading position of the container crane 10 for the crane spreader 11 to load the container 30 on.

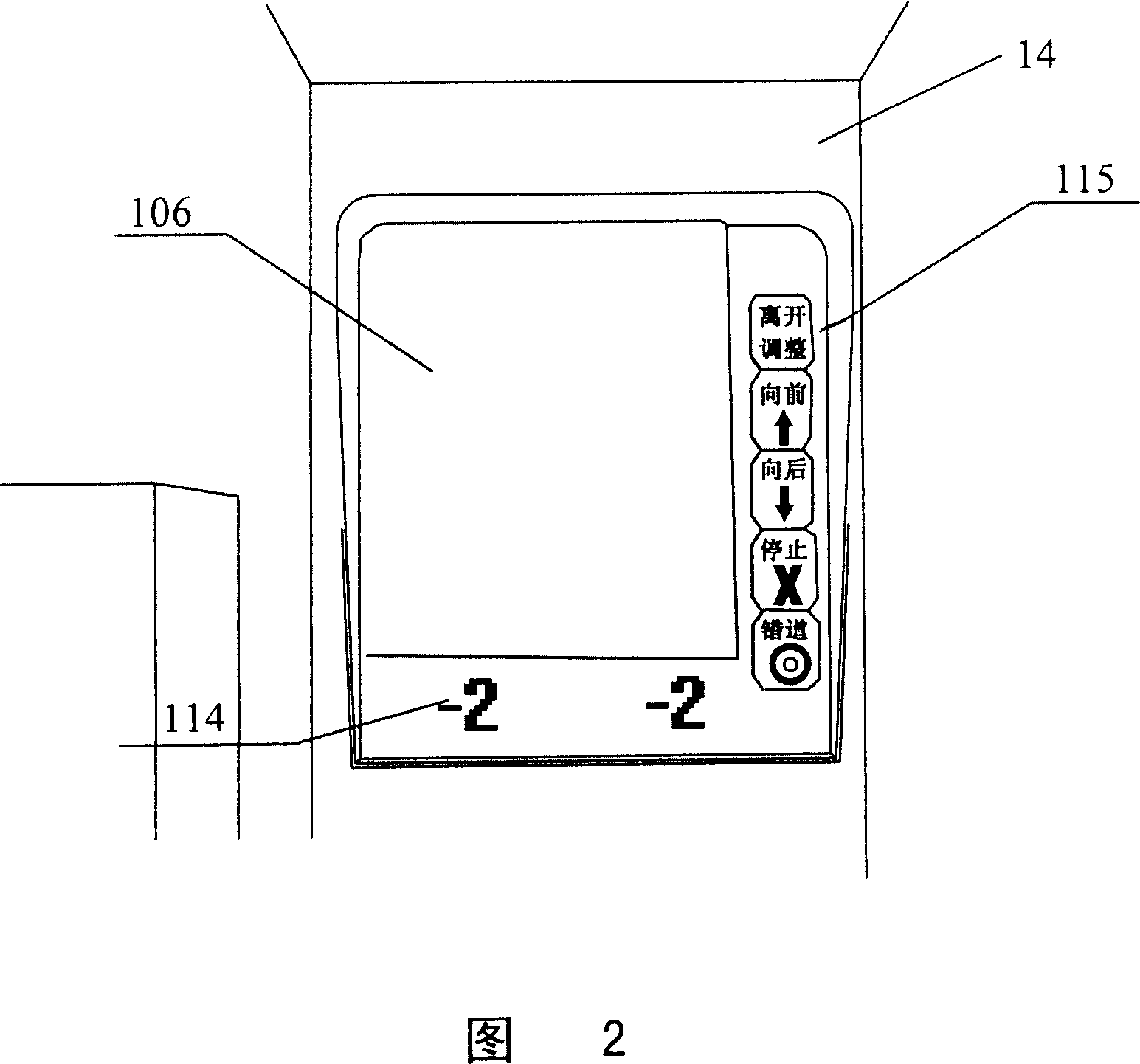

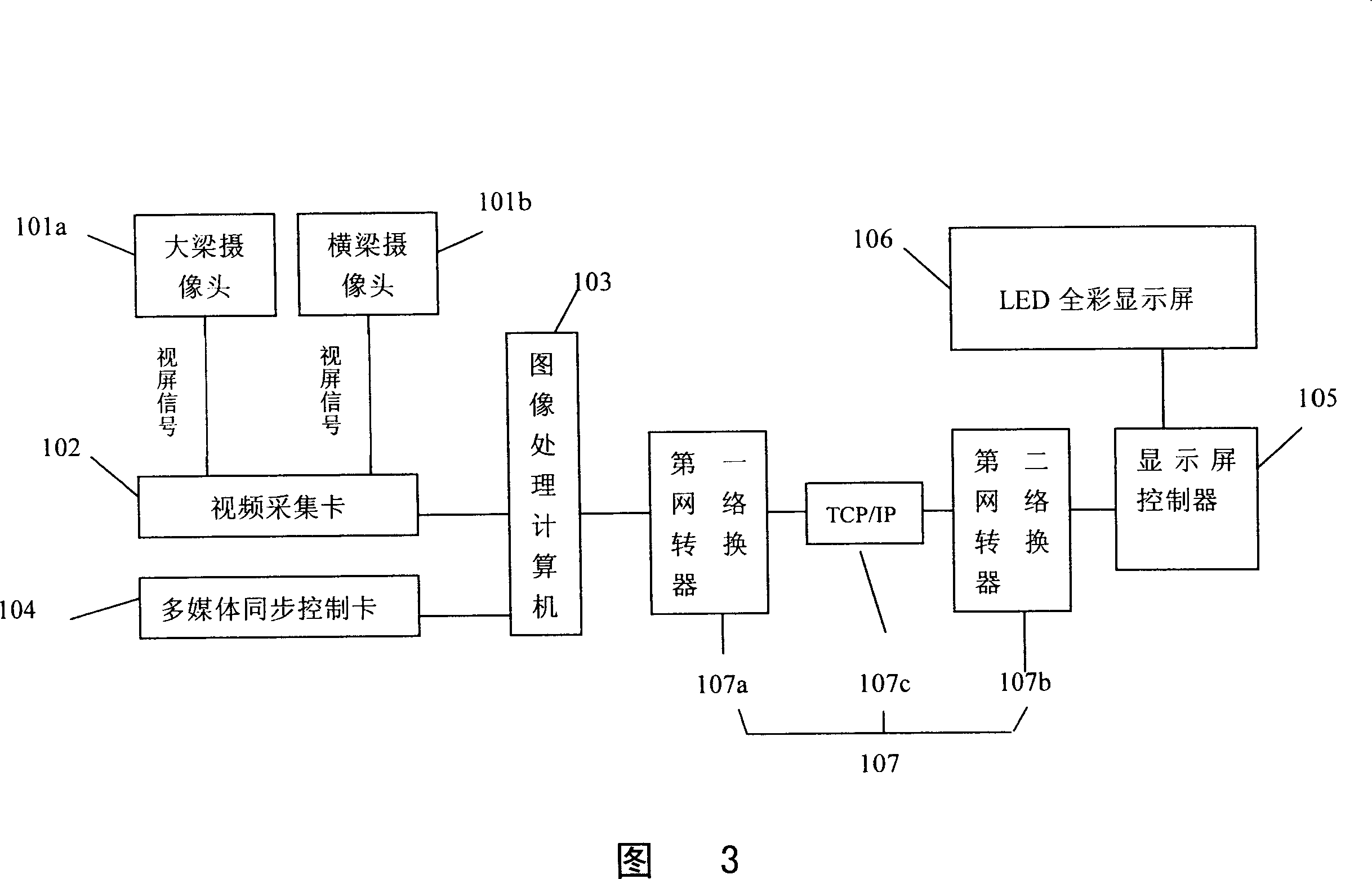

[0055] The truck alignment system of the present invention is divided into an image display pre-positioning subsystem 100 and a scanning positioning display subsystem 110 . Wherein the structural schematic diagram of image display pre-positioning subsystem 100 is as shown in Figure 3, comprising image pickup device 101, video capture card 102 connected to image capture device 101, image processing computer 103 connected to video capture card 102, connected to image processing The multimedia synchronization control card 104 of the computer 103 , the display screen controller 105 , the display screen 106 , and the first transmission network 107 connected between the image processing computer 103 and the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com