Screw sliding table

A sliding table and screw technology, which is applied in gear lubrication/cooling, mechanical energy control, transmission parts, etc., can solve the problems that the sliding table is not stable enough, the moving distance cannot reach the expected distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

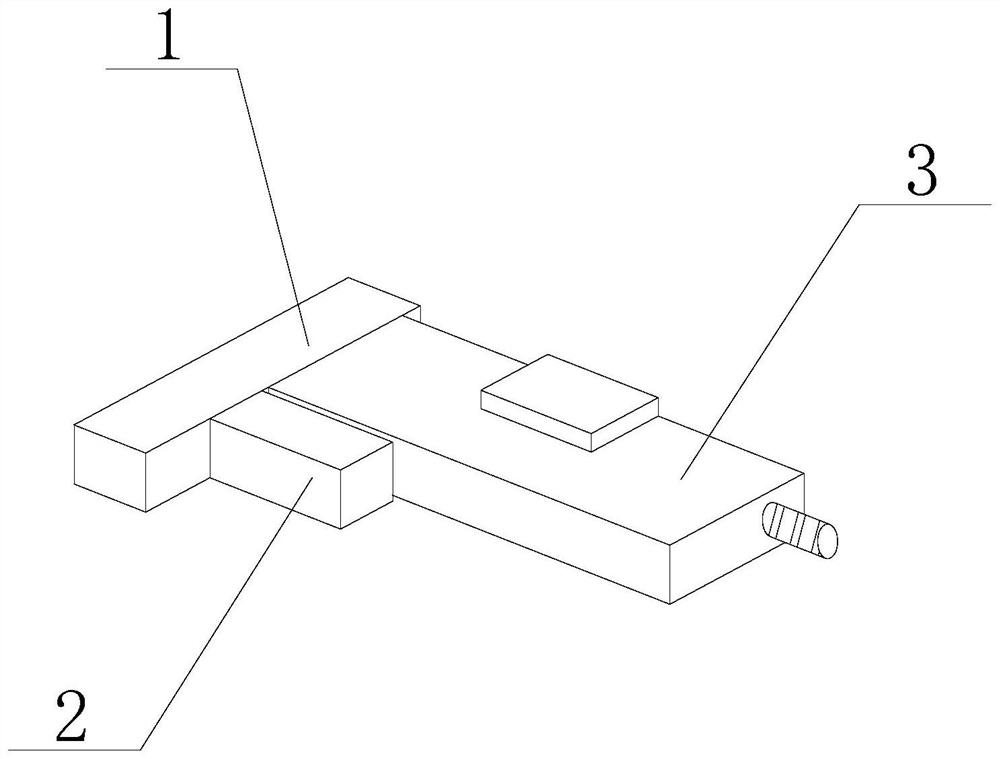

[0023] Such as figure 1 As shown, the present invention provides a screw slide table, including a bearing table 1, a servo motor 2 and a slide table main body 3, the bottom of the servo motor 2 is movably installed on the top of the bearing table 1, and the bottom of the slide table main body 3 is fixedly installed on the On the top of the carrying platform 1 , the terminal of the servo motor 2 is electrically connected to the terminal of the sliding table main body 3 .

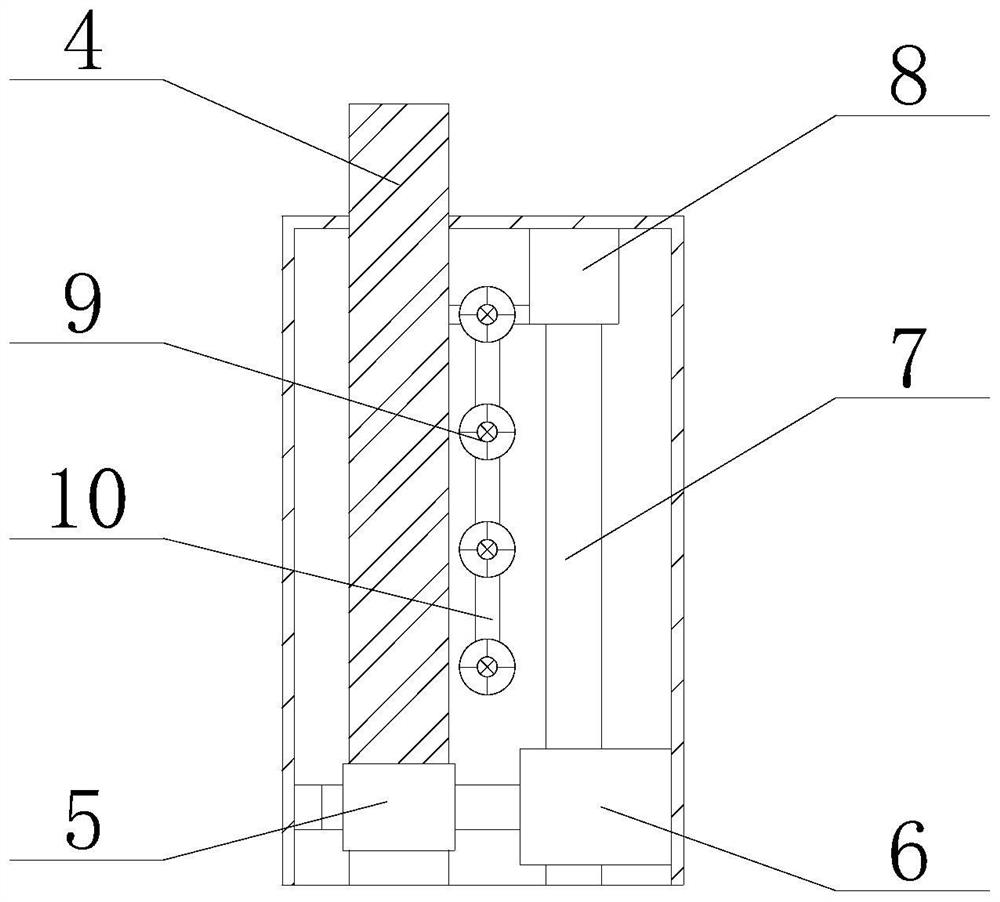

[0024] Specifically, such as figure 2 As shown, the main body 3 of the sliding table includes a screw 4, an active slider 5, a driven positioning block 6, a positioning guide rod 7 and an air storage chamber 8, the screw 4 runs through the main body 3 of the sliding table, and the inner wall of the active sliding block 5 is threadedly connected to the screw On the outer wall of 4, one end of the active slider 5 is fixedly connected with one end of the driven positioning block 6, the positioning guide rod 7 ...

Embodiment 2

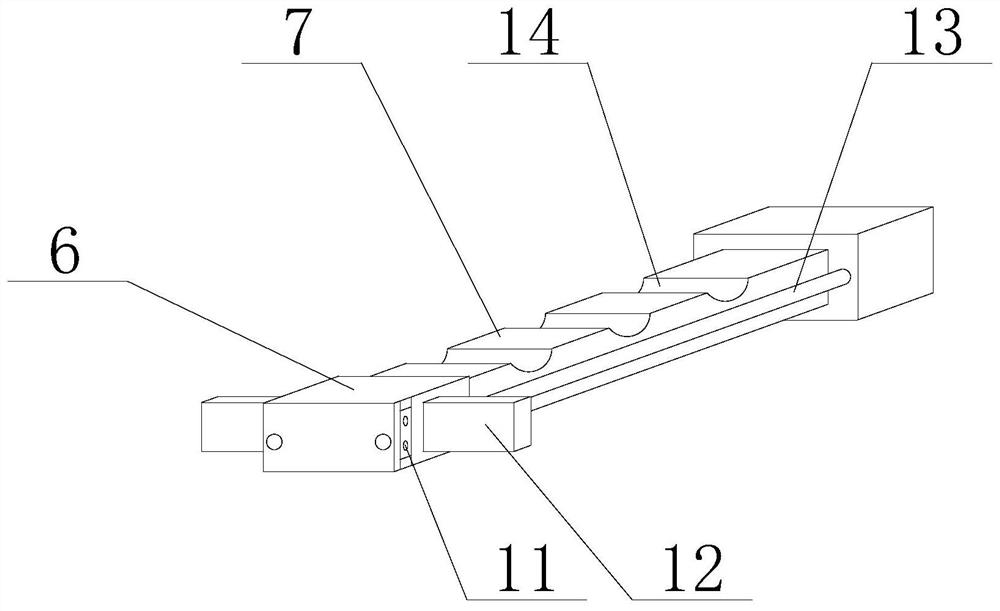

[0027] Such as image 3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: one side of the driven positioning block 6 is provided with a power groove 11, and the inside of the driven positioning block 6 is fixedly installed with a transmission guide rod 12, and the power groove 11 is electrically connected with the transmission guide rod 12, and a gas production pipeline 13 is fixedly installed between the driven positioning block 6 and the gas storage chamber 8, and one end of the gas production pipeline 13 runs through the driven positioning block 6, and the gas production pipeline 13 The other end is fixedly connected to the inside of the air storage chamber 8 .

[0028] The above-mentioned embodiment provides that the servo motor 2 transmits power to the transmission guide rod 12 through the power tank 11, and then drives the active slider 5 through the transmission guide rod 12 to achieve the purpose of driving the active slider 5...

Embodiment 3

[0030] Such as figure 2 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, one side of the gas storage chamber 8 is provided with an air guide pipe 10, and the top of the air guide pipe 10 is fixedly installed with a cleaning Head 9, cleaning head 9 comprises control valve 15 and rebound jet hole 16, and the bottom of rebound jet hole 16 is movably installed in the inside of control valve 15, and the bottom of control valve 15 is fixedly connected in the inside of air guide pipe 10.

[0031] Specifically, such as Figure 4 As shown, the control valve 15 includes a gas separation layer 17, an injection layer 18 and a transmission platform 19, the bottom of the transmission platform 19 is movably connected to the inside of the injection layer 18, and one end of the gas separation layer 17 is fixedly connected to the bottom of the injection layer 18, and the transmission The platform 19 is pneumatically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com