Automatic grabbing mechanism

A grasping mechanism and automatic technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of low utilization rate of grasping mechanism, low production efficiency, and inability to apply products of different sizes, so as to improve equipment utilization rate, The effect of fast grabbing speed and avoiding product scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

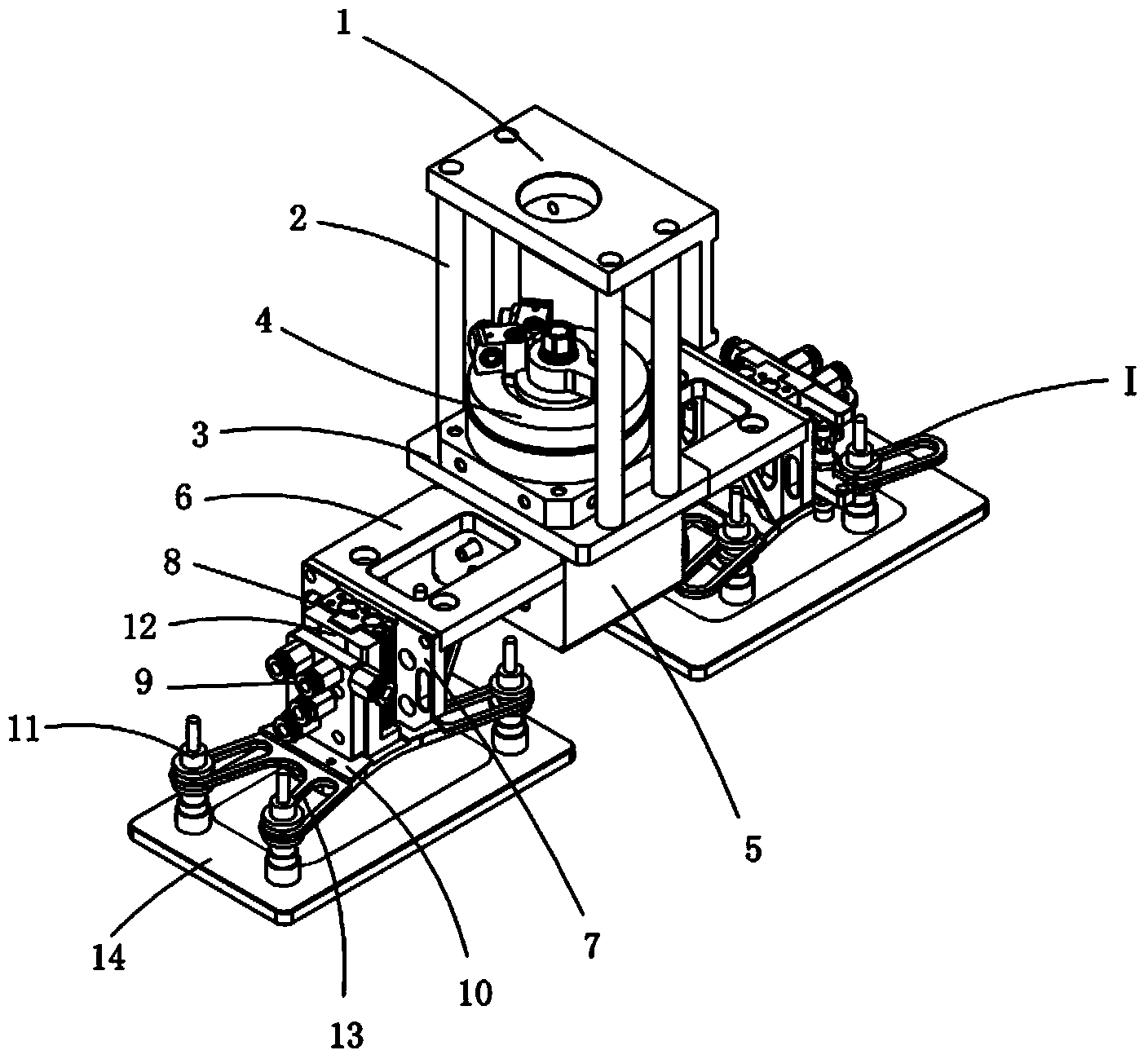

[0015] Examples, see attached figure 1 , an automatic grabbing mechanism, which includes a connecting plate 1, a supporting column 2, a rotating cylinder mounting plate 3, a rotating cylinder 4, a vacuum generator placement box 5 and a grabbing mechanism I. There are four supporting columns, the upper end of which is It is fixedly connected with the connection plate, and the lower end of the support column is fixedly connected with the rotary cylinder mounting plate; the rotary cylinder is mounted on the rotary cylinder mounting plate, and a vacuum generator placement box is installed under the rotary cylinder mounting plate, and the rotary shaft of the rotary cylinder is connected to the The vacuum generator placement boxes are connected together; a set of grasping mechanisms are respectively installed on both sides of the vacuum generator placement box; the two sets of grasping mechanisms can rotate 180°C through the rotating cylinder, and can alternately grasp products.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com