Catapulting type fast grabbing robot

A robotic and catapult technology, applied in manipulators, manufacturing tools, etc., can solve the problems of small operation range, slow grasping speed of bionic grasping robots, weak stretching ability, etc., to solve the problems of limited grasping space, simple structure, Grab long distance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

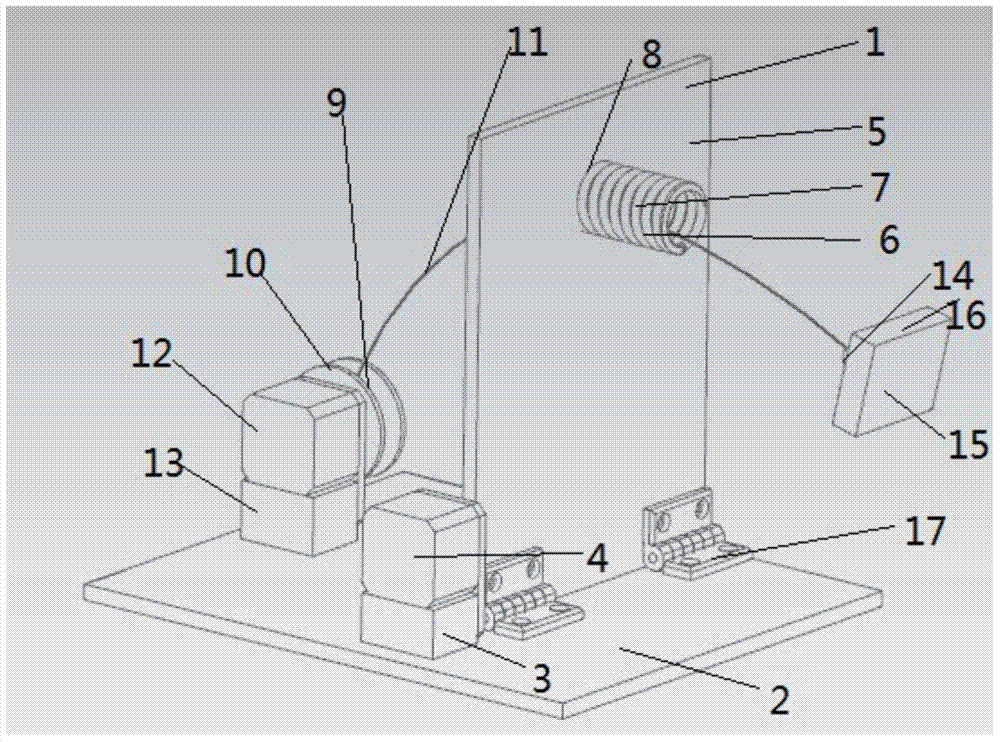

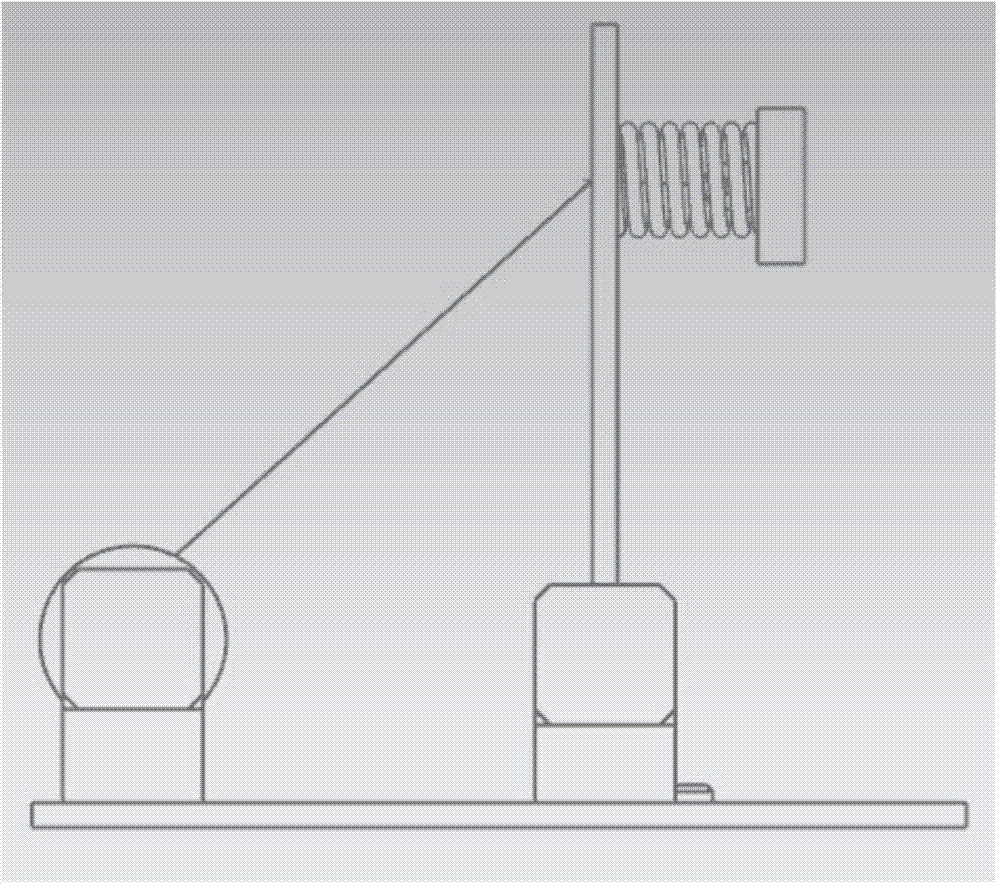

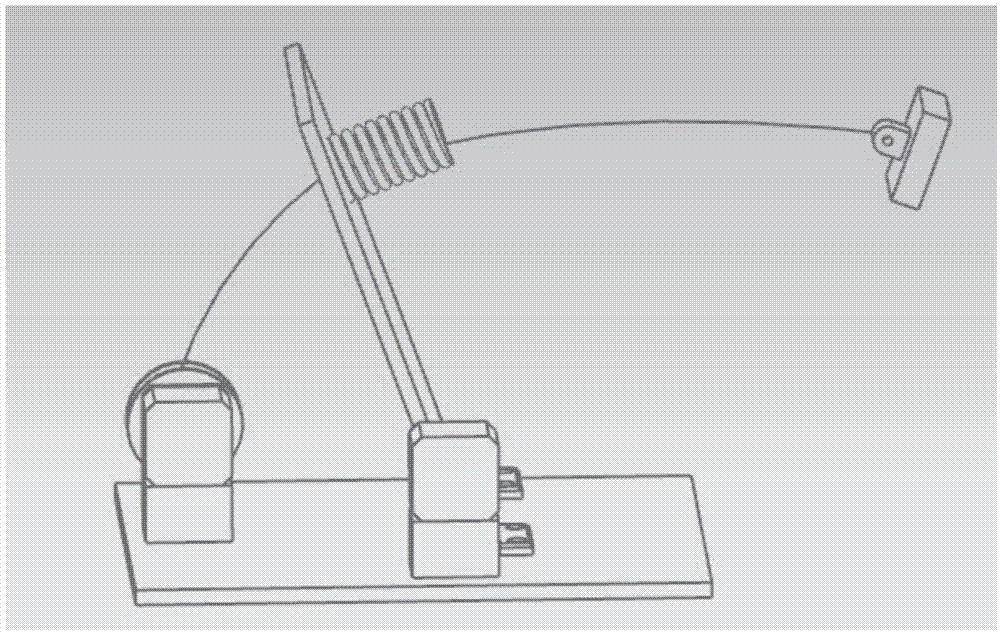

[0016] Below in conjunction with accompanying drawing, the present invention is explained in detail, as figure 1 , a kind of catapult fast grasping robot, comprises direction adjustment mechanism 1, base 2, launching mechanism 6, retraction mechanism 9 and adhesion grasping mechanism 14; Described direction adjustment mechanism (1) is controlled by servomotor one (4) , a direction adjustment plate (5) and a hinge (17), the direction adjustment plate (5) is installed on the base (2) through the hinge (17), and the support is fixed on the base (2) One (3), servomotor one (4) is installed on the support one (3), and the output shaft of the servomotor one (4) is connected to the direction adjustment plate (5); the launching mechanism (6) is composed of a compression spring ( 7) and connection device one (8), one end of the compression spring (7) is fixed on the side of the direction adjustment plate (5) through the connection device one (8); the contraction mechanism (9) is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com