Catapulting type fast grabbing robot

A robot and ejection technology, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unable to meet the requirements of grasping speed and slow grasping speed, and achieve the effect of compact structure, convenient operation and improved grasping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

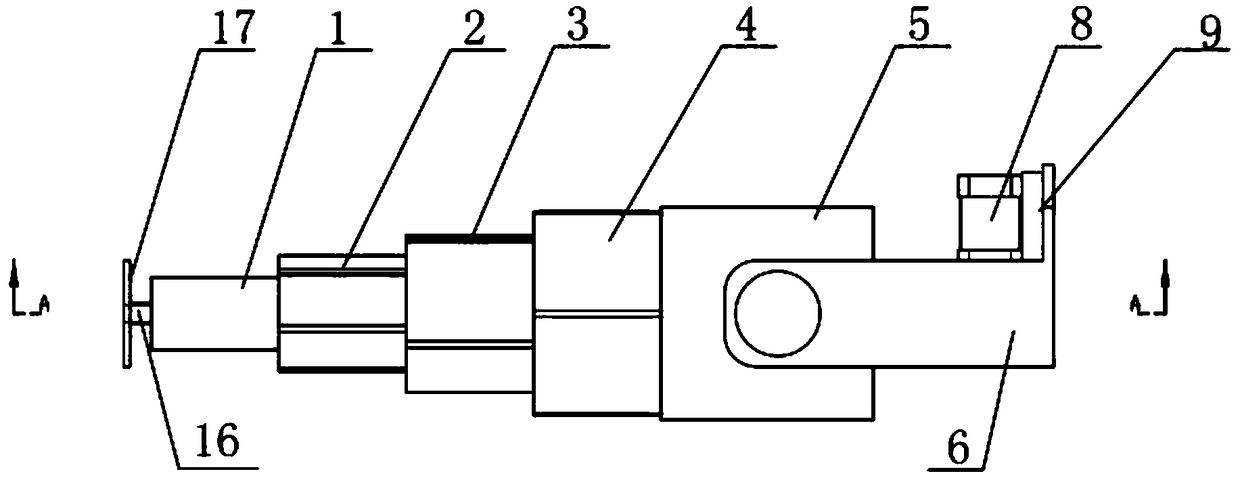

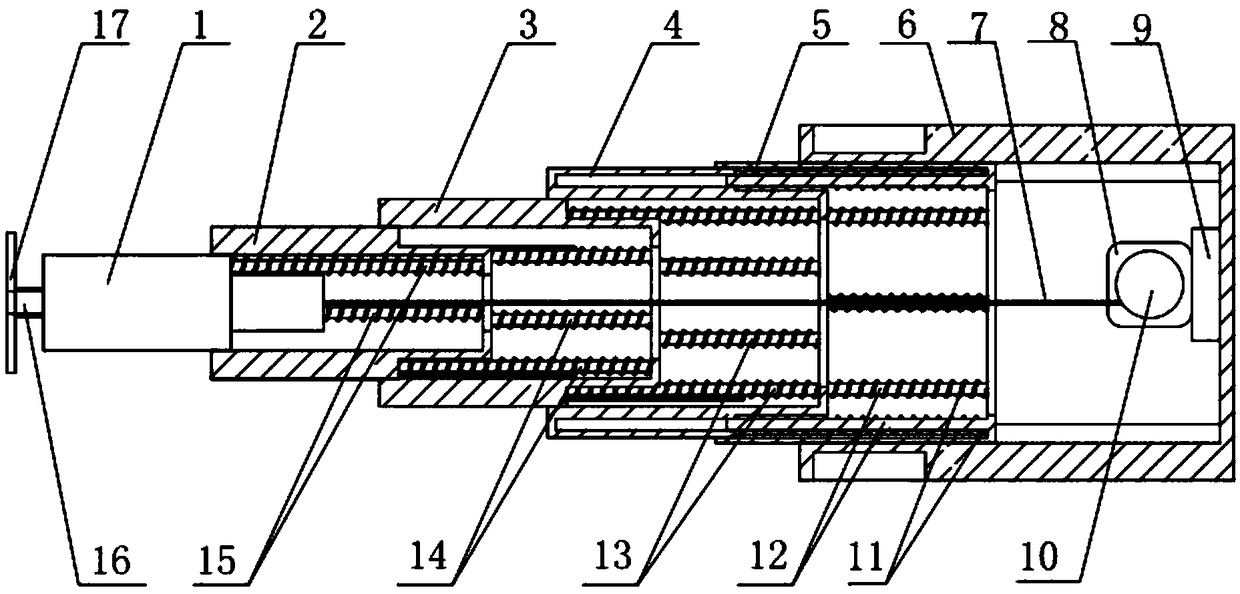

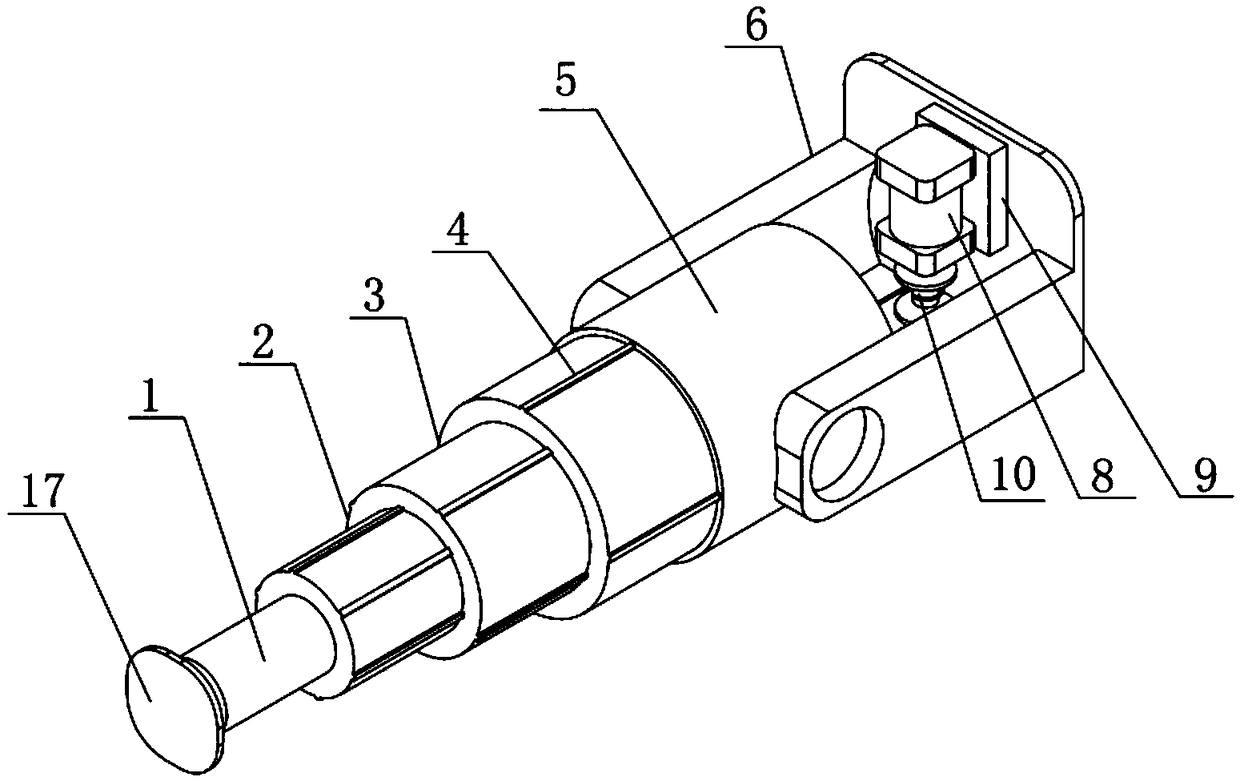

[0022] Such as figure 1 , figure 2 and image 3 As shown, the ejection-type fast grabbing robot of this embodiment includes a launching mechanism, a base 6, a shrinking mechanism and an adhesion grabbing mechanism. The base 6 is in a U-shaped structure, and a launching mechanism is arranged in the U-shaped structure. The launching mechanism includes Sleeve 1 5, sleeve 2 4, sleeve 3 3 and sleeve 4 2 are nested and connected in order from large to small. Both sides of sleeve 1 5 are welded and fixed in the U-shaped structure, and sleeve 4 2 is nested Connected with the end 1 of the launch mechanism, the walls of the sleeve two 4, sleeve three 3 and sleeve four 2 are provided with a number of grooves, between adjacent sleeves, and between the sleeve four 2 and the end 1 of the launch mechanism. Connected by a plurality of cylindrical pins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com