Double-component chemical-reaction thixotropic polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof and chemical reaction technology, applied in the field of architectural waterproof coatings, can solve the problems of relatively strict raw material restrictions and narrow application range, achieve good thixotropy, and solve the effect of serious flow in facade construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw material ratio:

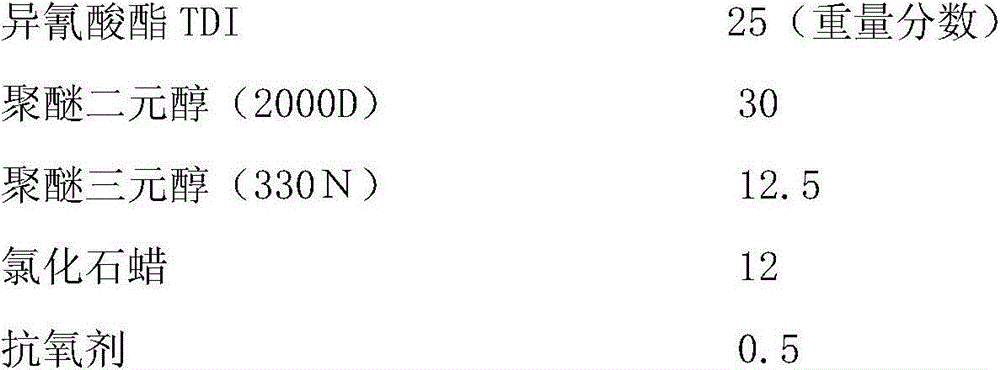

[0031] A component:

[0032]

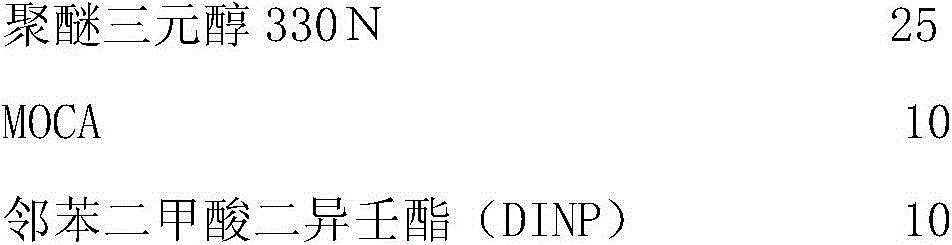

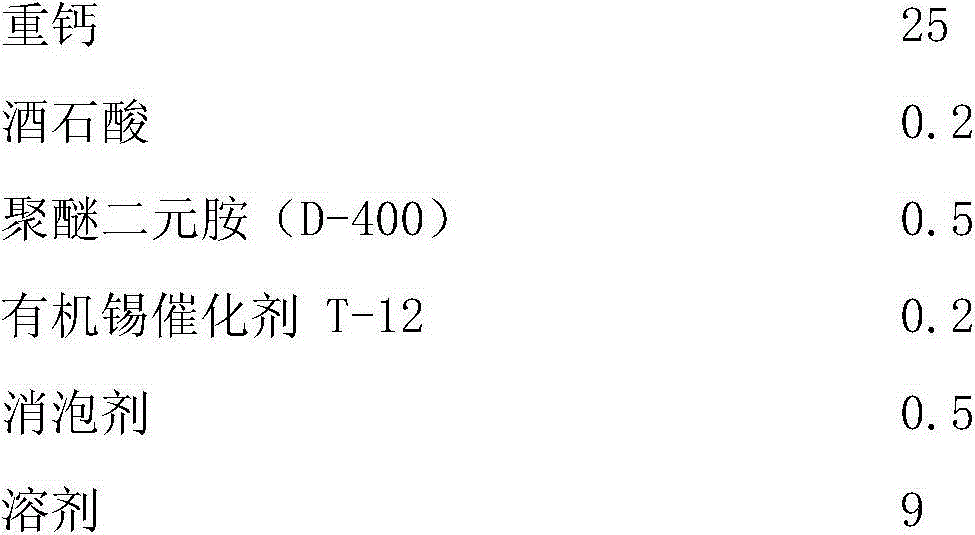

[0033] B component:

[0034]

[0035]

[0036] crafting process:

[0037] A component:

[0038] a. Add 20-50 parts by weight of polyether polyol into the reaction vessel, stir and heat up to 100°C-130°C, and dehydrate for 2-3 hours under the condition of vacuum of -0.01MPa;

[0039] b. Lower the temperature below 60°C-80°C, add 20-40 parts by weight of isocyanate, and react for 2-3 hours under stirring at 60-100°C;

[0040] c. Lower the temperature to below 50°C-60°C, add 5-15 parts by weight of plasticizer and 0-1 part by weight of high-performance additives, lower the temperature to below 30°C-40°C and fill with nitrogen for protection, and discharge to obtain Group A point.

[0041] B component:

[0042]a. Add 20-40 parts by weight of polyether polyols, 5-30 parts by weight of chain extenders, 5-20 parts by weight of plasticizers, and pigments and fillers of 20-40 parts by weight in the reaction vess...

Embodiment 2

[0046] Raw material ratio:

[0047] A component:

[0048]

[0049] B component:

[0050]

[0051] crafting process:

[0052] Same as Example 1.

[0053] During construction, components A and B are mixed evenly at a weight ratio of 1:2.

Embodiment 3

[0055] Raw material ratio:

[0056] A component:

[0057]

[0058] B component:

[0059]

[0060]

[0061] crafting process:

[0062] Same as Example 1.

[0063] During construction, components A and B are mixed evenly at a weight ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com