Reaction type polyurethane hot melt adhesive as well as preparation method and application thereof

A polyurethane hot-melt adhesive, reactive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor water permeability, difficult application of hot-melt adhesive for car lights, water leakage of car lights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the reactive polyurethane hot-melt adhesive described in the above-mentioned technical scheme, comprising the following steps:

[0050] Mix polyester polyol, polyether polyol, antioxidant and tackifying resin, then dehydrate, then add isocyanate and chain extender to react, and finally add filler and catalyst for vacuum defoaming, and evenly disperse to obtain reactive polyurethane heat Melt glue.

[0051] The present invention first mixes polyester polyol, polyether polyol, antioxidant and tackifying resin; The process of described mixing is preferably specifically:

[0052] Mix polyester polyol, polyether polyol and antioxidant, heat up to 75°C to 85°C, then add tackifying resin to complete the mixing process.

[0053] In the present invention, the dehydration temperature is preferably 105°C to 130°C, more preferably 115°C to 120°C; the vacuum degree of the dehydration is preferably ≤ -0.095MPa; the dehydrat...

Embodiment 1

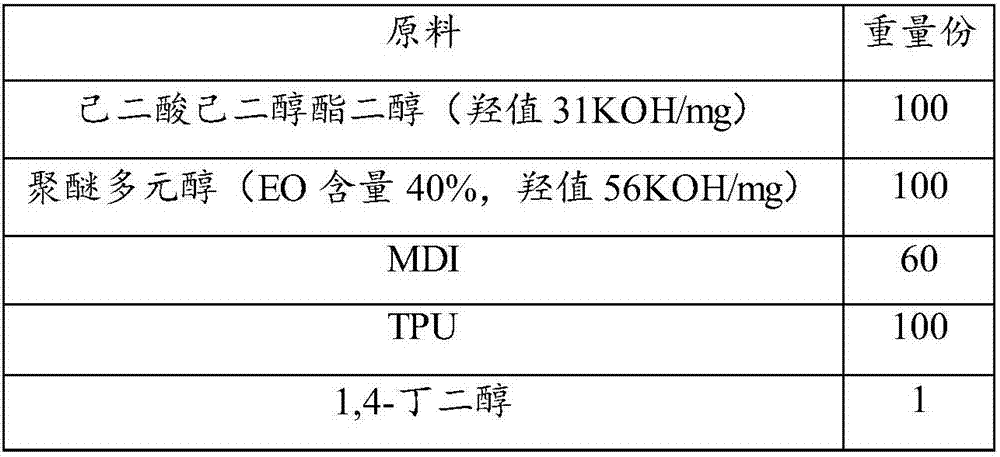

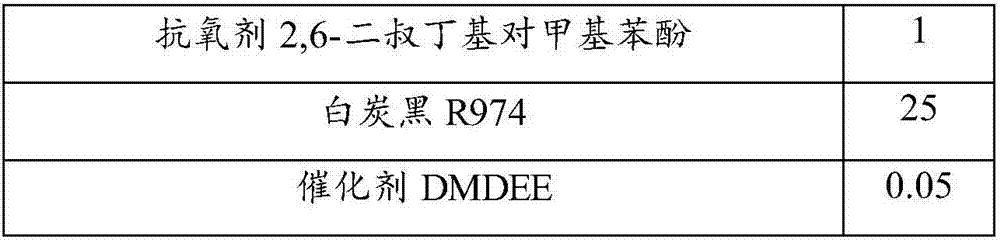

[0061] The formula quantity of the raw materials used in Example 1 is shown in Table 1.

[0062] The formula quantity of raw material used in table 1 embodiment 1

[0063] raw material

[0064] Add hexanediol adipate, polyether polyol and antioxidant into the reaction kettle according to the formula amount, raise the temperature to 80°C, then add the acrylic resin 2740 in the formula amount, raise the temperature to 115°C-120°C, Dehydrate for 2 hours under the condition of vacuum degree ≤-0.095MPa, until the water content is ≤500ppm, then cool down to 80°C, add the formulated amount of MDI, heat up to 95°C for 1h, then add 1,4-butanediol to continue the reaction for 1h, until After the reaction is complete, finally add the formulated amount of carbon black and catalyst DMDEE, vacuum degassing for 0.5h-1h, until the dispersion is uniform after stirring, then the glue can be discharged and filled, and the reactive polyurethane hot melt adhesive is obtained.

Embodiment 2

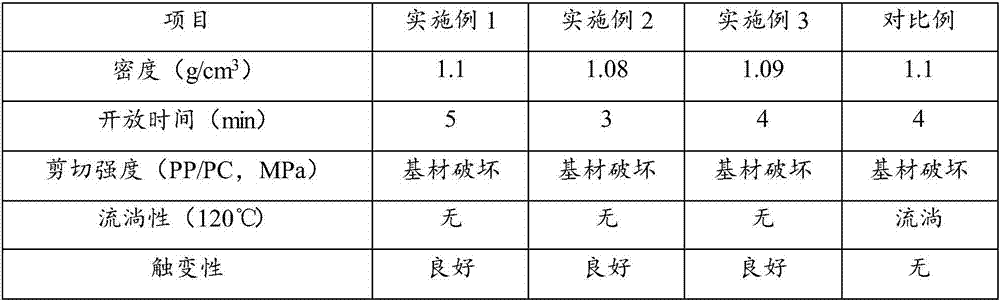

[0066] The formulation amount of the raw materials used in Example 2 is shown in Table 2.

[0067] The formula quantity of raw material used in table 2 embodiment 2

[0068]

[0069]

[0070] Add hexanediol adipate, polyether polyol and antioxidant into the reaction kettle according to the formula, raise the temperature to 80°C, then add the TPU in the formula amount, raise the temperature to 115°C~120°C, Dehydrate for 2 hours under the condition of ≤-0.095MPa, until the water content is ≤500ppm, then lower the temperature to 80°C, add the formulated amount of MDI, heat up to 95°C for 1 hour, then add 1,4-butanediol and continue the reaction for 1 hour until the reaction is complete , and finally add the formula amount of white carbon black R974 and catalyst DMDEE, vacuum degassing for 0.5h-1h, until the dispersion is uniform after stirring, then the glue can be filled, and the reactive polyurethane hot melt adhesive is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com