Dual-component high-thixotropy polyurethane adhesive

A polyurethane adhesive and thixotropy technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve problems such as incompatibility of the system, and achieve the effect of improving thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The highly thixotropic polyurethane adhesive of the present embodiment is specifically as follows:

[0024] Component A: Weigh 24kg of castor oil, 15kg of polyoxypropylene glycol, 2kg of 1,4-butanediol, 1kg of glycerin in a 150L reaction kettle, heat and vacuumize at 100°C for 1h, planetary speed at 30Hz, and then add to the gas phase 3kg of silicon dioxide, 50kg of calcium carbonate, 5kg of 4A molecular sieve, at this time, the planetary speed is 30HZ, the dispersion is 1000rpm, and then the vacuum is turned on -0.1Mpa, defoaming for about 20min, and the material is discharged.

[0025] Component B: Composed of polymethylene polyphenylisocyanate.

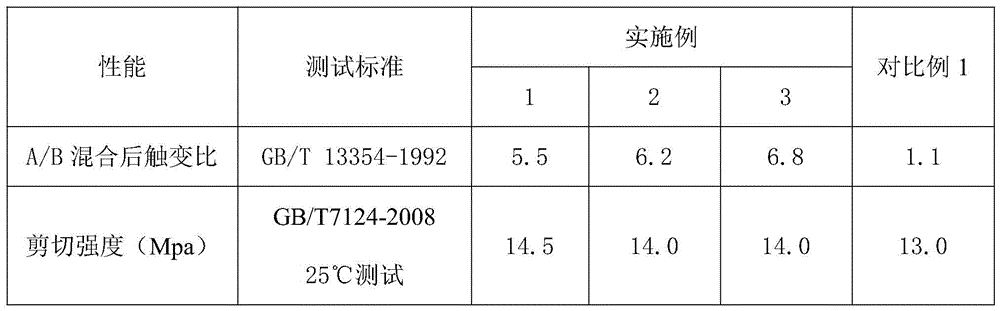

[0026] Mix components AB at a mass ratio of 100:20 to make shear samples and impact samples, and cure them at room temperature at 25°C for 7 days to test the shear strength of samples at room temperature and the thixotropic ratio of glue A.

Embodiment 2

[0028] The highly thixotropic polyurethane adhesive of the present embodiment is specifically as follows:

[0029] Component A: Weigh 22kg of castor oil, 17kg of polyoxypropylene triol, 1kg of 1,4-butanediol, 1kg of glycerin in a 150L reaction kettle, heat and vacuumize at 100°C for 1h, and then add the gas phase 4kg of silicon dioxide, 50kg of calcium carbonate, 5kg of 3A molecular sieve, at this time, the planetary speed is 30Hz, the dispersion is 1000rpm, then the vacuum is turned on -0.1Mpa, defoaming for about 20min, and the material is discharged.

[0030] Component B: Composed of polymethylene polyphenylisocyanate.

[0031] Mix components AB at a mass ratio of 100:20 to make shear samples and impact samples, and cure them at room temperature at 25°C for 7 days to test the shear strength of samples at room temperature and the thixotropic ratio of glue A.

Embodiment 3

[0033] The highly thixotropic polyurethane adhesive of the present embodiment is specifically as follows:

[0034] Component A: Weigh 24kg of castor oil, 16kg of polyoxyethylene glycol, 3kg of 1,3-propanediol, 1kg of glyceryl monostearate in a 150L reactor, heat and vacuumize at 100°C for 1h, planetary speed 30Hz, Then add 5kg of fumed silicon dioxide, 50kg of silicon micropowder, and 5kg of 4A molecular sieve. At this time, the planetary speed is 30Hz, and the dispersion is 1000rpm. Then turn on the vacuum -0.1Mpa, defoam for about 20min, and discharge.

[0035] Component B: Composed of polymethylene polyphenylisocyanate.

[0036] Mix components AB at a mass ratio of 100:20 to make shear samples and impact samples, and cure them at room temperature at 25°C for 7 days to test the shear strength of samples at room temperature and the thixotropic ratio of glue A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com