Manufacturing method for improving PCBA production efficiency

A manufacturing method and technology of production efficiency, applied in the direction of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as damage to the health of operators, high technical personnel requirements, easy leakage and poor maintenance, etc., to eliminate flux pollution, Reduce costs, eliminate the effects of the wave soldering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

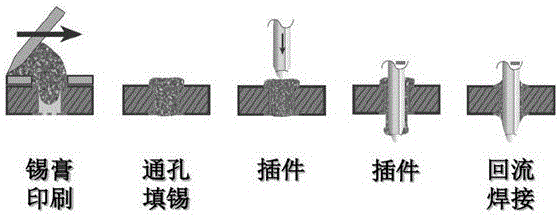

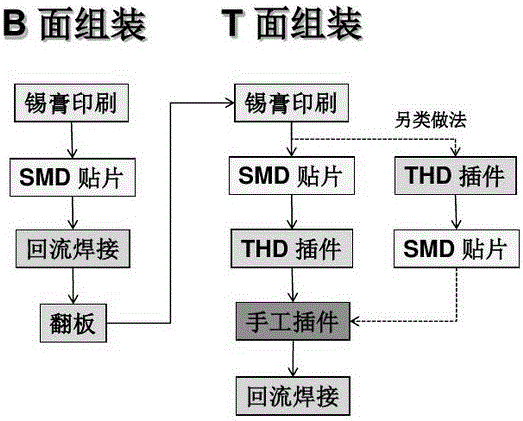

[0031] The manufacturing method for improving PCBA production efficiency of the present invention is completed by one-time reflow soldering, which avoids soldering flux pollution to the PCB caused by wave soldering again, and improves product production quality. The manufacturing method for improving PCBA production efficiency specifically includes the following steps:

[0032] S1: According to the layout and characteristics of the components on the PCB board, make a printed steel plate with special openings to ensure that the volume of solder paste at the position of the DIP material meets the welding requirements.

[0033] Add bridges and ribs to the openings of the printed steel plate, and use stepped steel plates if necessary, which can effectively prevent the solder paste from falling during the reflow process and improve product quality.

[0034] Solder paste has high viscosity, strong wetting, not easy to volatilize, flux and green oil are compatible, so as to improve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com