Honing solution and preparation method thereof

A technology of honing fluid and anti-rust agent, which is applied in the field of honing fluid and its preparation, can solve the problems of waste fluid discharge, environmental pollution, impact on operator health, and operator hazards, and achieve human and environmental friendliness, eliminate pollution sources, and prolong tool life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of honing fluid, according to mass percentage, including 20% oleic acid diethanolamine borate, 15% polyethylene glycol oleate, 10% rust inhibitor, 2% triazine fungicide, 0.5% EDTA disodium salt, 0.2% silicone defoamer, the balance is water.

[0024] Wherein, the antirust agent is prepared by the following method: after mixing triethanolamine and undecanedibasic acid in a molar ratio of 3:1, react at 70° C. for 30 minutes to obtain the antirust agent.

[0025] The preparation method of the above-mentioned honing fluid is as follows: add triethanolamine and undecanedibasic acid in a molar ratio of 3:1 into the reaction kettle, then react at 70°C for 30 minutes under stirring to obtain a rust inhibitor, and then calculate by mass percentage , Add 20% oleic acid diethanolamine borate to 10% rust inhibitor, 15% polyethylene glycol oleate, 2% triazine fungicide, 0.5% EDTA disodium salt, 0.2% The organosilicon defoamer, after stirring evenly, add water, and then stir...

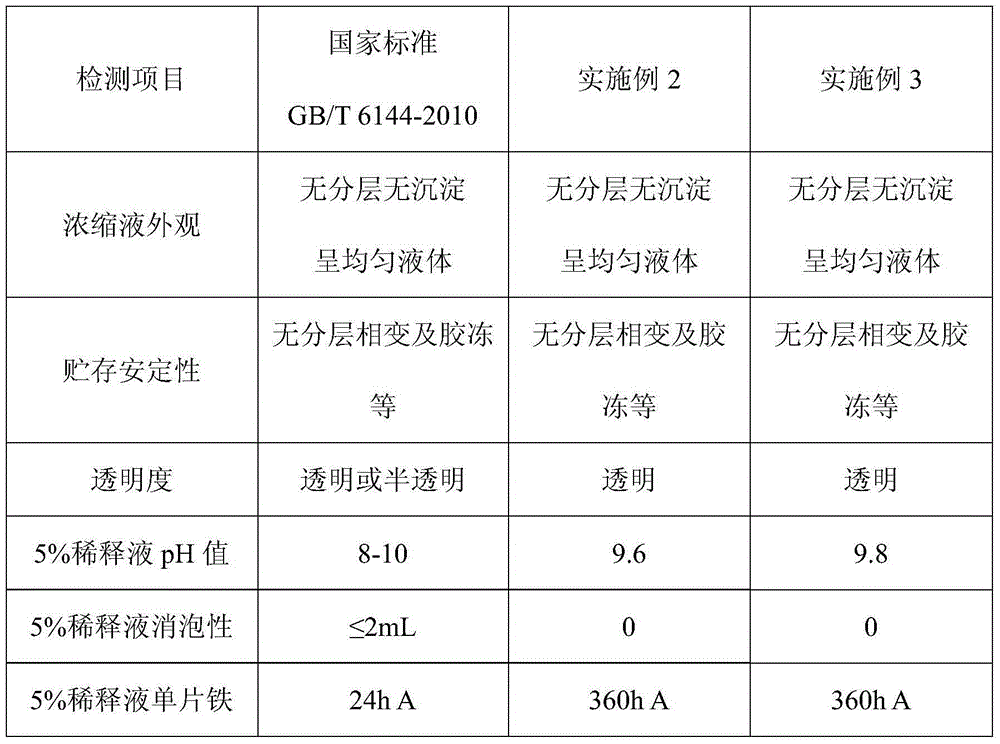

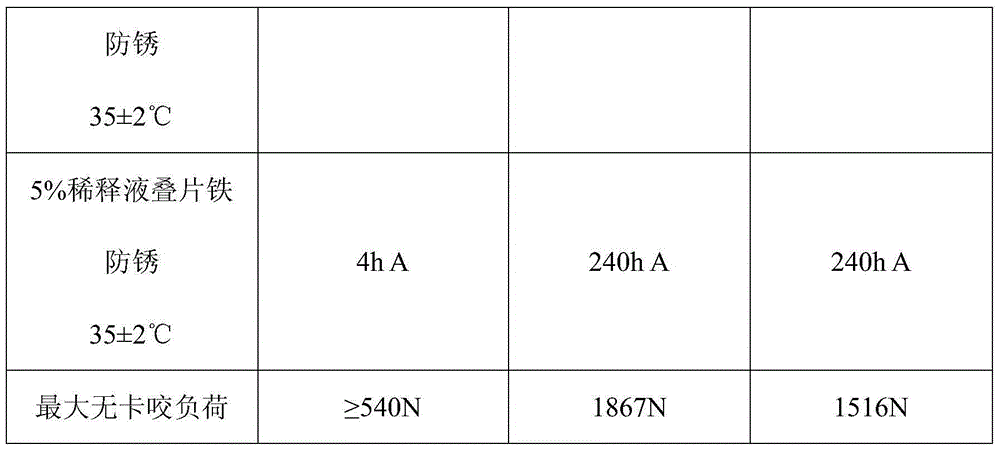

Embodiment 2

[0027] A kind of honing fluid, according to mass percentage, including 20% oleic acid diethanolamine borate, 15% polyethylene glycol, 10% antirust agent, 3% methylene bismorpholine, 0.5% EDTA disodium salt, 0.2% silicone defoamer, the balance is water.

[0028] Wherein, the antirust agent is prepared by the following method: after mixing triethanolamine and dodecenylsuccinic acid in a molar ratio of 3:1, react at 80° C. for 30 minutes, and obtain the antirust agent after the reaction is complete.

[0029] The preparation method of the above-mentioned honing fluid is as follows: add triethanolamine and dodecenylsuccinic acid in a molar ratio of 3:1 into the reaction kettle, then react at 80°C for 30 minutes under stirring to obtain a rust inhibitor, and then Calculate, add 20% oleic acid diethanolamine borate, 15% polyethylene glycol, 3% methylenebismorpholine, 0.5% EDTA disodium salt, 0.2% The organosilicon defoamer, after stirring evenly, add water, and then stir evenly to...

Embodiment 3

[0031] A kind of honing fluid, according to mass percentage, including 15% oleic acid diethanolamine borate, 15% polyethylene glycol, 10% rust inhibitor, 1% 1,2-benzisothiazole-3 - Ketone, 0.5% EDTA disodium salt, 0.2% silicone defoamer, the balance is water.

[0032] Wherein, the antirust agent is prepared by the following method: after mixing triethanolamine and sebacic acid in a molar ratio of 3:1, react at 75° C. for 30 minutes to obtain the antirust agent.

[0033] The preparation method of the above-mentioned honing liquid is as follows: add triethanolamine and sebacic acid in a molar ratio of 3:1 into the reaction kettle, then react at 75°C for 30 minutes under stirring to obtain a rust inhibitor, and then add it to 10 Add 15% oleic acid diethanolamine borate, 15% polyethylene glycol, 1% 1,2-benzisothiazol-3-one, 0.5% EDTA disodium salt, 0.2% organic silicon defoamer, after stirring evenly, add water, and then stir evenly to obtain a honing fluid, wherein the sum of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com