Wafer heater assembly

A technology of heating components and heaters, applied in semiconductor/solid-state device manufacturing, electrical components, gaseous chemical plating, etc., can solve problems such as difficult control, wafer warping, metal contamination, etc., and achieve the effect of improving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

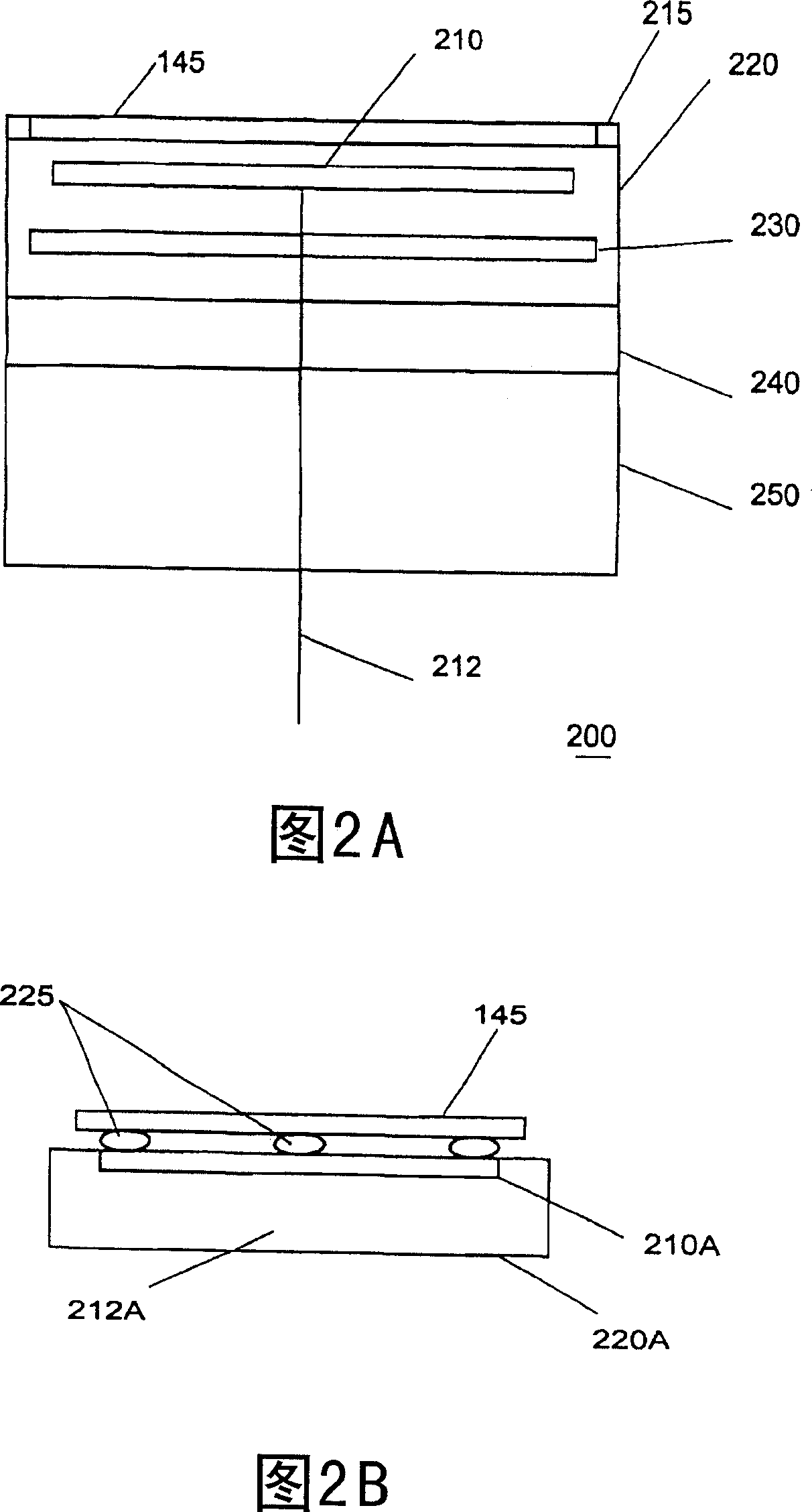

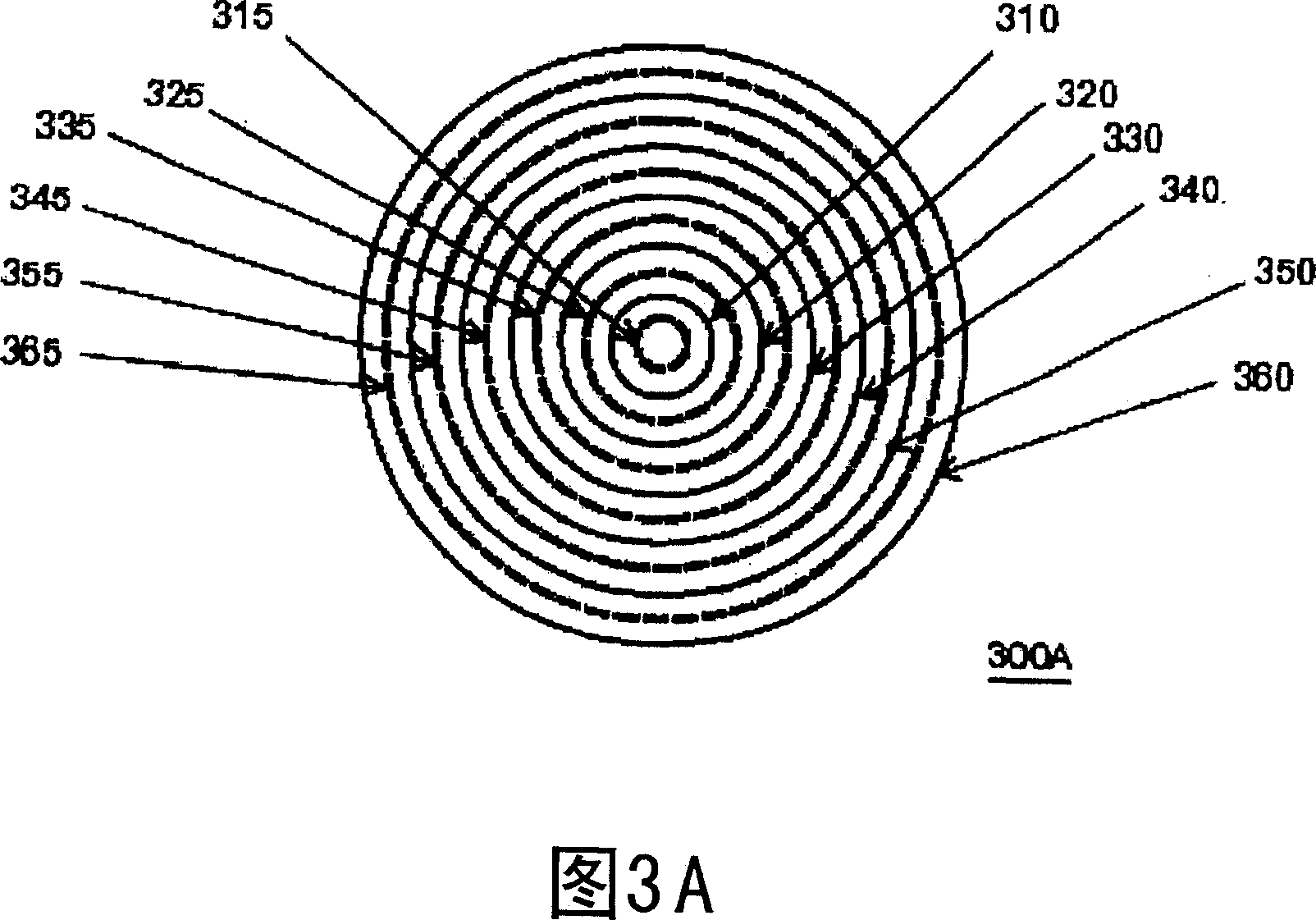

[0027] In materials processing systems, substrates and / or wafers are positioned on a holder, such as a chuck, that includes heating and / or cooling elements. In one embodiment of the present invention, an improved holder is provided that includes a unique heating element comprising high purity carbon wires embedded in quartz.

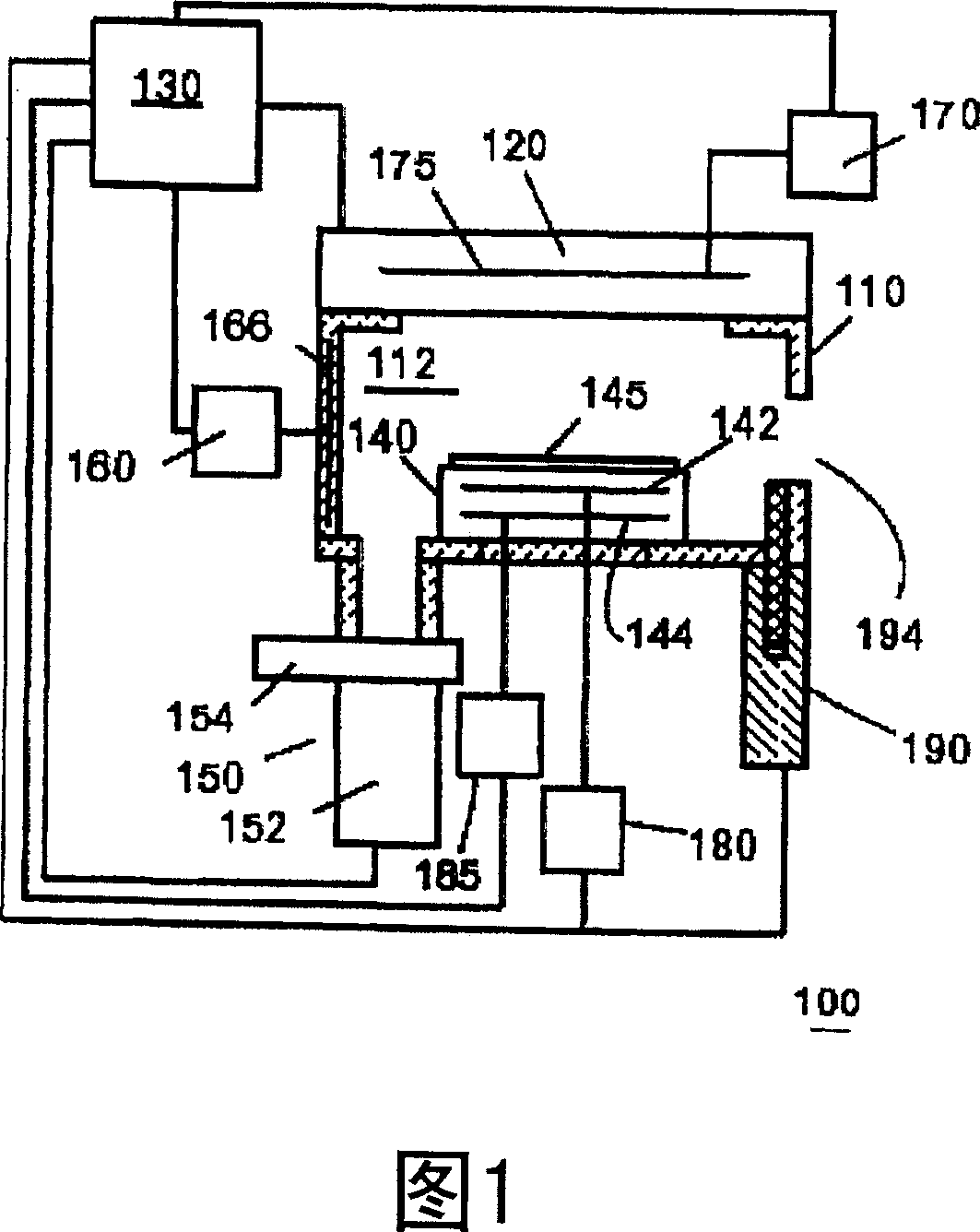

[0028] FIG. 1 shows an exemplary block diagram of a processing system according to an embodiment of the present invention. For example, processing system 100 may include an etching system such as a plasma etcher. Alternatively, processing system 100 may include a photoresist coating system, a patterning system, a development system, and / or a combination of these systems. In other embodiments, the processing system 100 may include thermal processing systems such as rapid thermal processing (RTP) systems, coating systems, chemical vapor deposition (CVD) systems, physical vapor deposition (PVD, iPVD) systems, atomic layer deposition (ALD) systems and / or c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com