Preparation method of trimetallic MOF-derived ternary cathode material

A positive electrode material and three-metal technology, which is applied in the field of preparation of three-metal MOF-derived ternary positive electrode materials, can solve the problems of poor safety and cycle stability of ternary batteries, achieve reduced formation, increase infiltration degree, and improve cycle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Trimetallic MOF derived ternary positive electrode material and preparation method thereof comprise the following steps:

[0029] Add nickel salt, cobalt salt, manganese salt and organic ligand (5-10mmol) with a molar ratio of x:y:1-x-y:1 to 60ml of solvent, stir for 30min and mix well, then put it into the reaction kettle, React in an oven at 110-150°C for 24-48h, wash three times with one or more of DMF, methanol and ethanol, and then centrifugally dry at 105-135°C for 12-24h to obtain a trimetallic MOF product; the nickel, Cobalt and manganese salts are one or more of nitrates, chlorides and acetates; the organic ligands are 2,5-dihydroxyterephthalic acid, 1,4-terephthalic acid, One or more of 1,3,5-benzenetricarboxylic acid and 1,2,4,5-benzenetetracarboxylic acid; the solvent used is one or more of DMF, methanol and ethanol.

[0030] The obtained tri-metallic MOF material and lithium source were mixed by high-speed ball milling at a molar ratio of 1:1.08-1.3, and t...

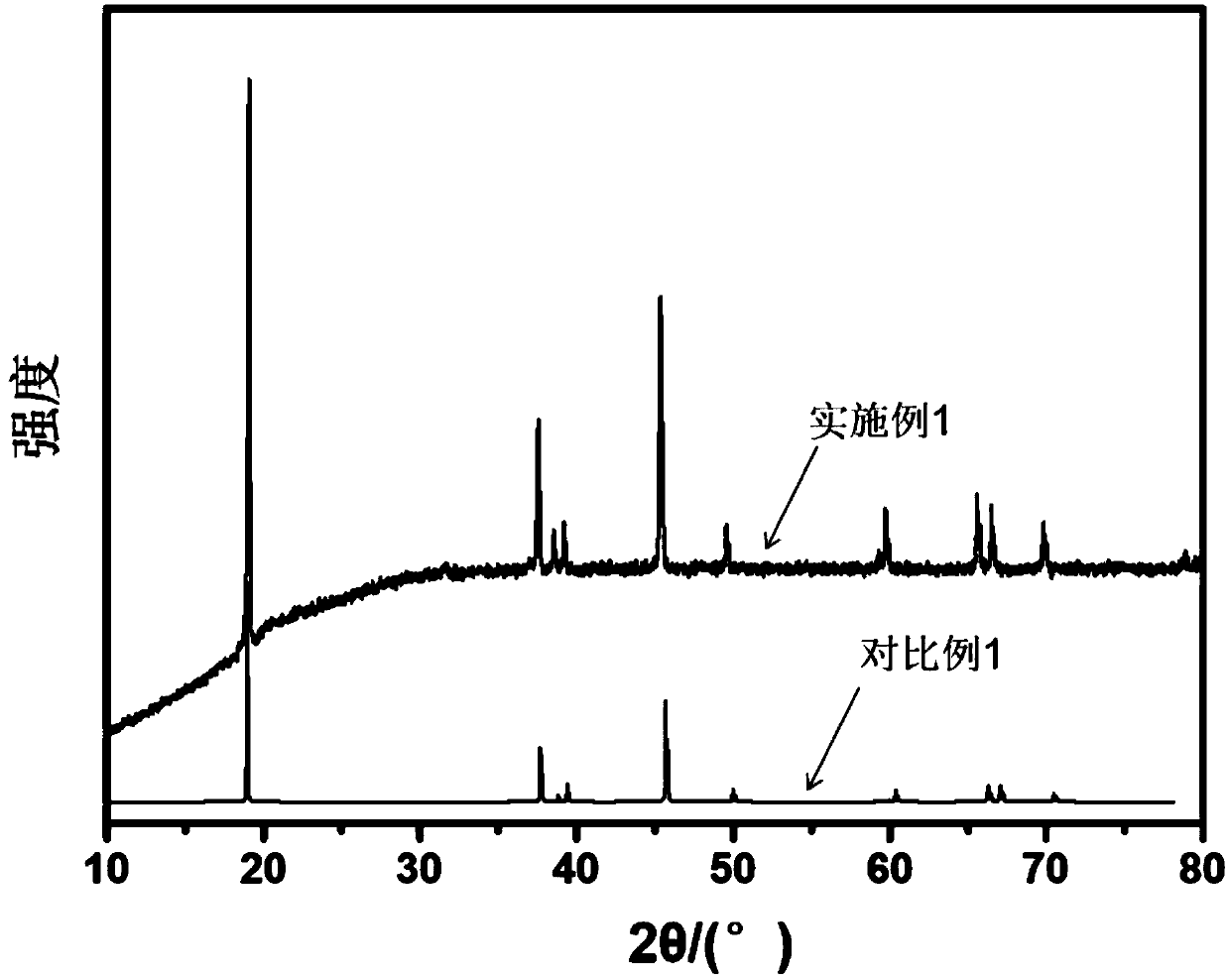

Embodiment 1

[0032] A method for preparing a trimetallic MOF-derived ternary cathode material, the obtained material is abbreviated as NCM-MOF-74:

[0033]1) Preparation of trimetallic MOF precursor, accurately weigh 7.2mmol nickel nitrate, 2.4mmol cobalt nitrate, 2.4mmol manganese nitrate and 12mmol 2,5-dihydroxyterephthalic acid, add 60mL DMF and absolute ethanol (3:1 ) in the mixed solution, stirred thoroughly, ultrasonically dispersed for 30min, placed in a 135°C oven for hydrothermal reaction for 24h, cooled to room temperature naturally, filtered or centrifuged, washed with DMF and ethanol three times, and then soaked in aqueous methanol overnight. Replace the solvent molecules in the structure, and finally dry at 110°C to obtain Ni 0.6 co 0.2 mn 0.2 - MOF-74;

[0034] 2) Then weigh Ni with a molar ratio of 1:1.08 0.6 co 0.2 mn 0.2 -MOF-74 with LiOH·H 2 O was mixed by ball milling in acetone solvent, then heated up to 350°C at a rate of 5°C / min, N 2 Keep it under the atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com