A high fluidity, bending, halogen-free, expansion flame retardant glass fiber reinforced polypropylene composite material for coil skeleton and its preparation method

A high-fluidity, coil skeleton technology, applied in the field of high-fluidity, bending-resistant, halogen-free, intumescent flame-retardant glass fiber reinforced polypropylene composite materials and their preparation, can solve the problem of not meeting the development trend of non-halogenation and failing to meet the flame retardant grade. applications, etc., to reduce dimensional instability, reduce interfacial tension, and improve the degree of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the high-fluidity bending-resistant halogen-free expansion flame-retardant glass fiber-reinforced polypropylene composite material used for the coil skeleton comprises the following steps:

[0061] 1) Preparation of flame retardant masterbatch: Weigh the raw materials according to the composition of the flame retardant masterbatch, first mix polypropylene copolymer, POE-g-MAH, hyperbranched polymer, active nano zinc oxide, antioxidant and lubricant , added to the main feeding port of the twin-screw extruder, and the nitrogen-phosphorus compound flame retardant was added from the side feeding port, extruded and granulated to obtain a flame-retardant masterbatch;

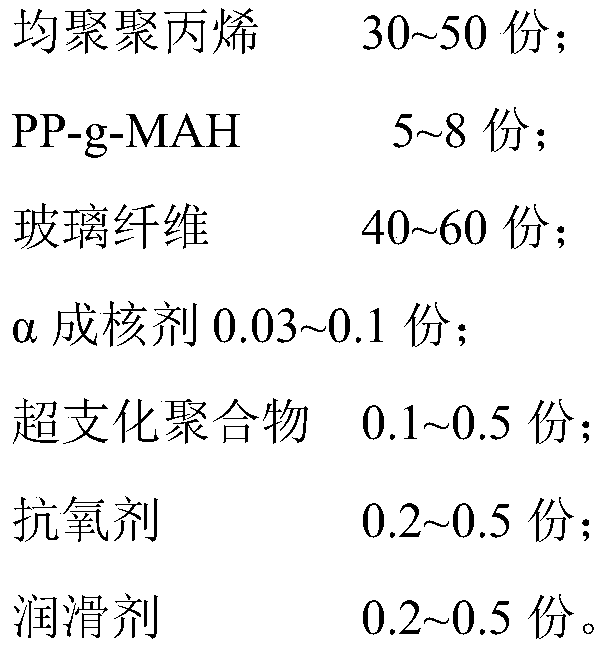

[0062] 2) Preparation of glass fiber masterbatch: Weigh the raw materials according to the composition of the glass fiber masterbatch, first mix homopolypropylene, PP-g-MAH, α nucleating agent, hyperbranched polymer, antioxidant and lubricant Mixing and sending to twin-screw extruder, ...

Embodiment 1

[0078] (1) Preparation of flame retardant masterbatch: 33 parts of BX3920, 5 parts of POE-g-MAH, 0.5 part of hyperbranched polymer, 0.5 part of active nano-zinc oxide, 0.4 part of antioxidant and 0.6 part of lubricant were processed at high speed After stirring and mixing evenly, add it from the main feeding port, and then add 60 parts of nitrogen-phosphorus compound flame retardant into the extruder from the side feeding in two times, and finally obtain particles with a length of about 3.5mm, which are flame retardant The agent content is 60% flame retardant masterbatch.

[0079] (2) Preparation of glass fiber masterbatch: first stir 44 parts of H7900, 5 parts of PP-g-MAH and 1‰ white oil (the purpose of adding is to absorb nucleating agent and hyperbranched polymer), and then add 0.1 Part α nucleating agent, 0.3 part hyperbranched polymer, 0.3 part antioxidant, 0.3 part lubricant, after stirring evenly, after being plasticized by a twin-screw extruder with a length-to-diamet...

Embodiment 2

[0082] (1) Preparation of flame retardant masterbatch: 33 parts of BX3920, 5 parts of POE-g-MAH, 0.5 part of hyperbranched polymer, 0.5 part of active nano-zinc oxide, 0.4 part of antioxidant and 0.6 part of lubricant were processed at high speed After stirring and mixing evenly, add it from the main feeding port, and then add 60 parts of nitrogen-phosphorus compound flame retardant into the extruder from the side feeding in two times, and finally obtain particles with a length of about 3.5mm, which are flame retardant The agent content is 60% flame retardant masterbatch.

[0083] (2) Preparation of glass fiber masterbatch: first stir 34 parts of H7900, 5 parts of PP-g-MAH and 1‰ white oil (the purpose of adding is to absorb nucleating agent and hyperbranched polymer), and then add 0.1 Part α nucleating agent, 0.3 part hyperbranched polymer, 0.3 part antioxidant, 0.3 part lubricant, after stirring evenly, after being plasticized by a twin-screw extruder with a length-to-diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com