Method for preparing electrode of lithium-ion battery

A lithium-ion battery and electrode technology, applied in the field of lithium batteries, can solve the problems of rapid charge capacity decay and low cycle life, and achieve the effects of improving electrical conductivity, improving cycle life and improving wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

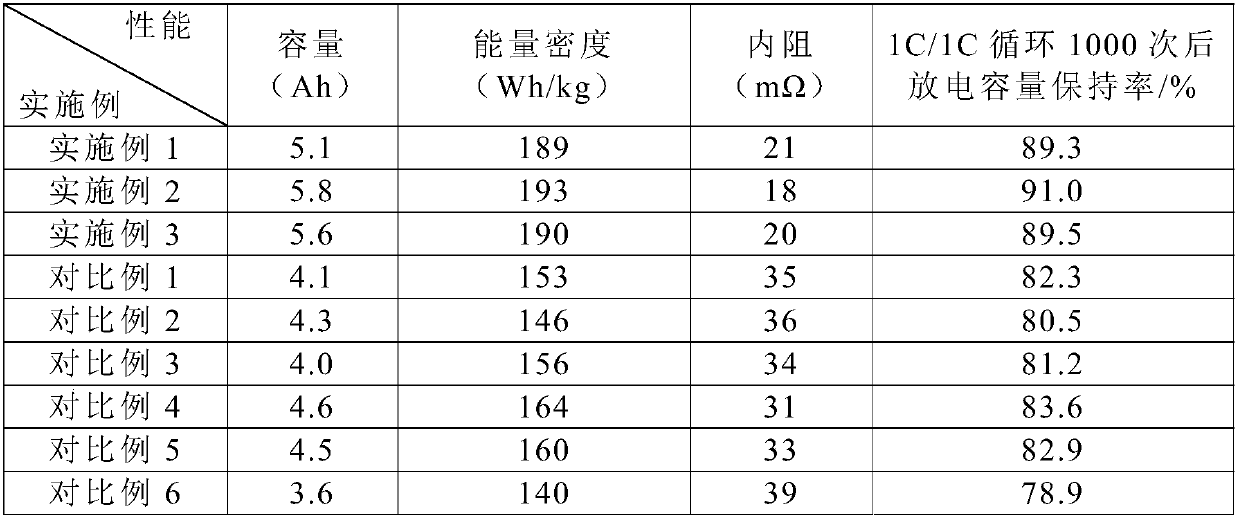

Examples

Embodiment 1

[0026] Lithium ion battery electrode is made according to the following steps in the present embodiment:

[0027] (1) Prepare a graphene oxide suspension, adopt the Hummers method to obtain graphene oxide, disperse the graphene oxide in deionized water after cleaning and drying, and form a graphene oxide suspension, store it in the dark for later use, graphite oxide The massfraction of graphene oxide in the olefin suspension is 5mg / L;

[0028] (2) Prepare the nano-silicon particle suspension, expose the fresh nano-silicon particles to the air for 10h under dark conditions, so that a uniform thin layer of SiO2 is formed on the surface of the fresh nano-silicon particles. 2 , and then ultrasonic treatment to disperse the silicon nanoparticles in deionized water to form a suspension of nano-silicon particles with a nano-silicon particle concentration of 6 mg / L;

[0029] (3) Add the graphene oxide suspension to the nano-silicon particle suspension, ultrasonically stir for 0.5, an...

Embodiment 2

[0032] Lithium ion battery electrode is made according to the following steps in the present embodiment:

[0033] (1) Prepare a graphene oxide suspension, adopt the Hummers method to obtain graphene oxide, disperse the graphene oxide in deionized water after cleaning and drying, and form a graphene oxide suspension, store it in the dark for later use, graphite oxide The massfraction of graphene oxide in the olefin suspension is 7mg / L;

[0034] (2) Prepare nano-silicon particle suspension, expose fresh nano-silicon particles to the air for 12h under dark conditions, and form a uniform thin layer of SiO on the surface of fresh nano-silicon particles 2 , and then sonicate to disperse the silicon nanoparticles in deionized water to form a suspension of nano-silicon particles with a concentration of 5 mg / L;

[0035] (3) The graphene oxide suspension is added to the nano-silicon particle suspension, ultrasonically stirred for 1.0h, and then suction filtered to form a layer of nano-...

Embodiment 3

[0038] Lithium ion battery electrode is made according to the following steps in the present embodiment:

[0039] (1) Prepare a graphene oxide suspension, adopt the Hummers method to obtain graphene oxide, disperse the graphene oxide in deionized water after cleaning and drying, and form a graphene oxide suspension, store it in the dark for later use, graphite oxide The massfraction of graphene oxide in the olefin suspension is 9mg / L;

[0040] (2) Prepare nano-silicon particle suspension, expose fresh nano-silicon particles to the air for 14h under dark conditions, and form a uniform thin layer of SiO on the surface of fresh nano-silicon particles 2 , and then sonicate to disperse the silicon nanoparticles in deionized water to form a suspension of nano-silicon particles with a concentration of 3 mg / L;

[0041] (3) Add the graphene oxide suspension to the nano-silicon particle suspension, ultrasonically stir for 1.5h, and then suction filter to form a layer of nano-silicon-gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com