Pelletizing production line for long-fiber composite material

A composite material, production line technology, applied in the direction of coating, etc., can solve the problem of the degree of infiltration of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

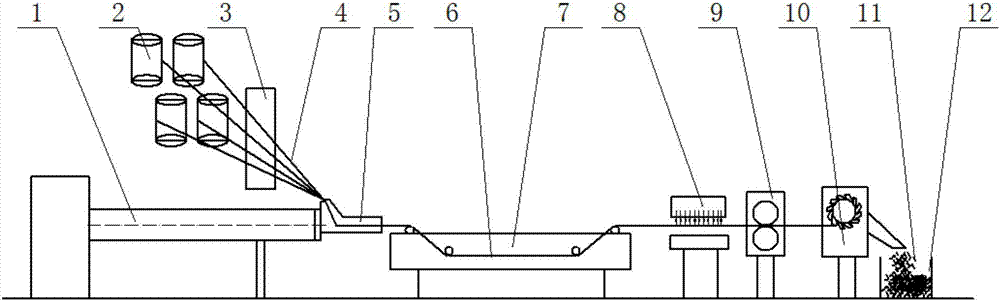

[0078] Such as figure 1The long-fiber composite material granulation production line shown is composed of extruder 1, long-fiber storage unit 2, long-fiber pretreatment unit 3, long-fiber soaking extrusion die 5, cooling system 7, air-drying system 8, traction system 9, Pelletizing system 10 and collection system 12 are made up; Wherein extruder 1 adopts twin-screw extruder (screw diameter 33mm, length-to-diameter ratio 40), to the polypropylene particle that melt index is 60g / 10min, antioxidant (1010 and 168) and the compatibilizer are melted, blended and extruded, and feed the long fiber soaking extrusion die 5 with a certain pressure; the long fiber 4 pulled out from the long fiber storage unit 2 is pretreated by the long fiber pretreatment unit 3 After heating and pre-dividing, the long fiber is introduced into the extrusion die 5, and compounded with the polymer melt to form the polymer wetted long fiber composite material 6; after the polymer wetted long fiber composite ...

Embodiment 2

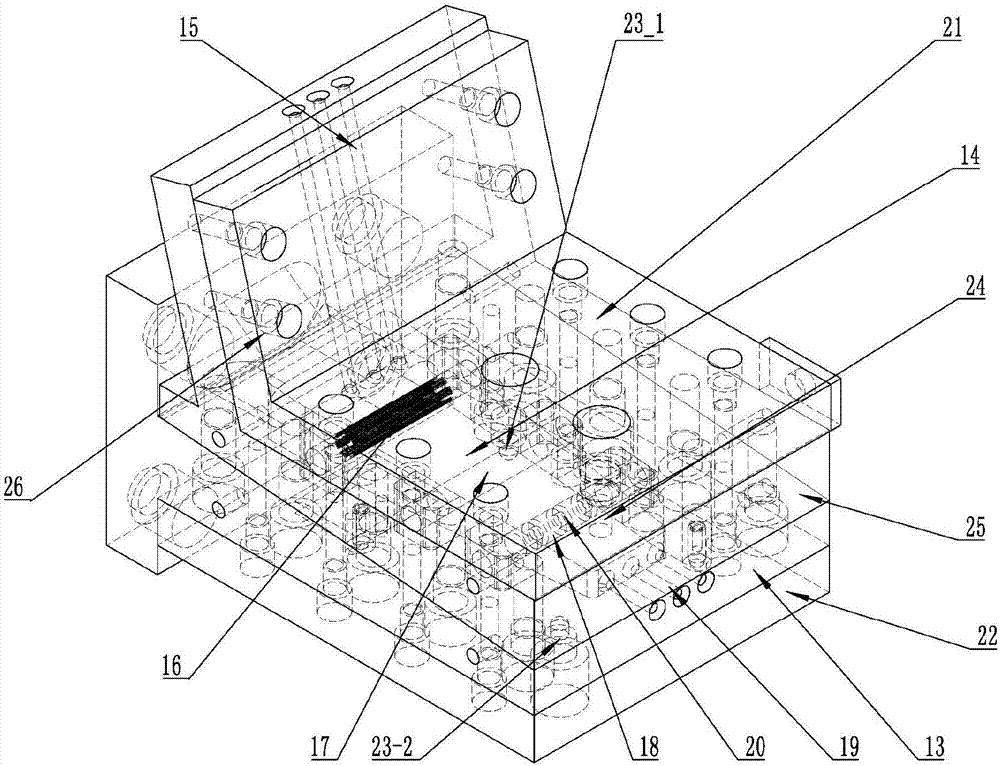

[0087] Based on Example 1, a filament infiltration die having a rectangular cross-sectional filament inlet was used. In order to facilitate the processing of rectangular holes, the mold upper plate is divided into two parts, such as Figure 8 Shown; Compared with embodiment 1, in embodiment 2, the upper plate processing cost of the mold increases to some extent, but the long fiber of 2400tex specification after the long fiber pretreatment unit is processed, after the long fiber of the rectangular cross-sectional shape that is 14mm in width When the fiber is introduced into the inlet, the long fiber is not gathered again; it is more conducive to the infiltration and bonding of the long fiber with the polymer melt in a more dispersed state in the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com