Battery separator, battery and preparation method of battery separator

A technology for battery separators and batteries, applied in secondary batteries, battery components, circuits, etc., can solve the problem of low liquid retention in battery separators, achieve improved long-term cycle performance, increase the degree of infiltration, and achieve a good interface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] See Figure 5 , the embodiment of the present invention provides a method for preparing a battery separator. Such as Figure 5 As shown, the method includes the following steps:

[0066] Step 501 , using a metal oxide or a carbonate compound as a hard template, through a hydrolysis reaction of tetraethyl orthosilicate, to obtain hybrid particles with a silicon dioxide layer on the outside and the hard template as the core.

[0067] Specifically, a metal oxide or a carbonate compound can be used as a hard template, ammonia water, a surfactant, and tetraethyl orthosilicate are added to stir the reaction and centrifuged to wash to obtain a silica shell containing the hard template as the core. hybrid particles.

[0068] In this step, in the embodiment of the present invention, based on the hard template method, using the principle that tetraethyl orthosilicate will be hydrolyzed under alkaline conditions to form silica spheres, using metal oxides or carbonates as hard t...

Embodiment 1

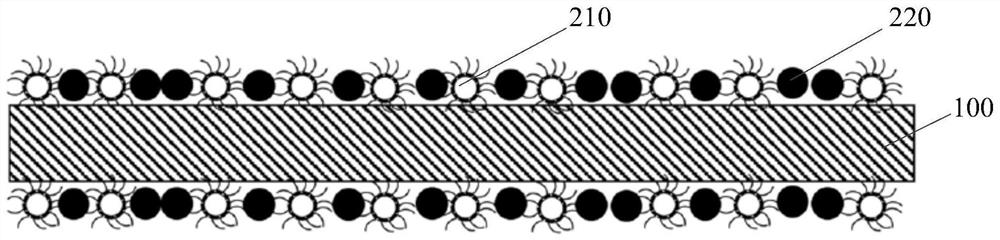

[0092] Embodiment 1, embodiment 1 can be made as image 3 Battery separator shown:

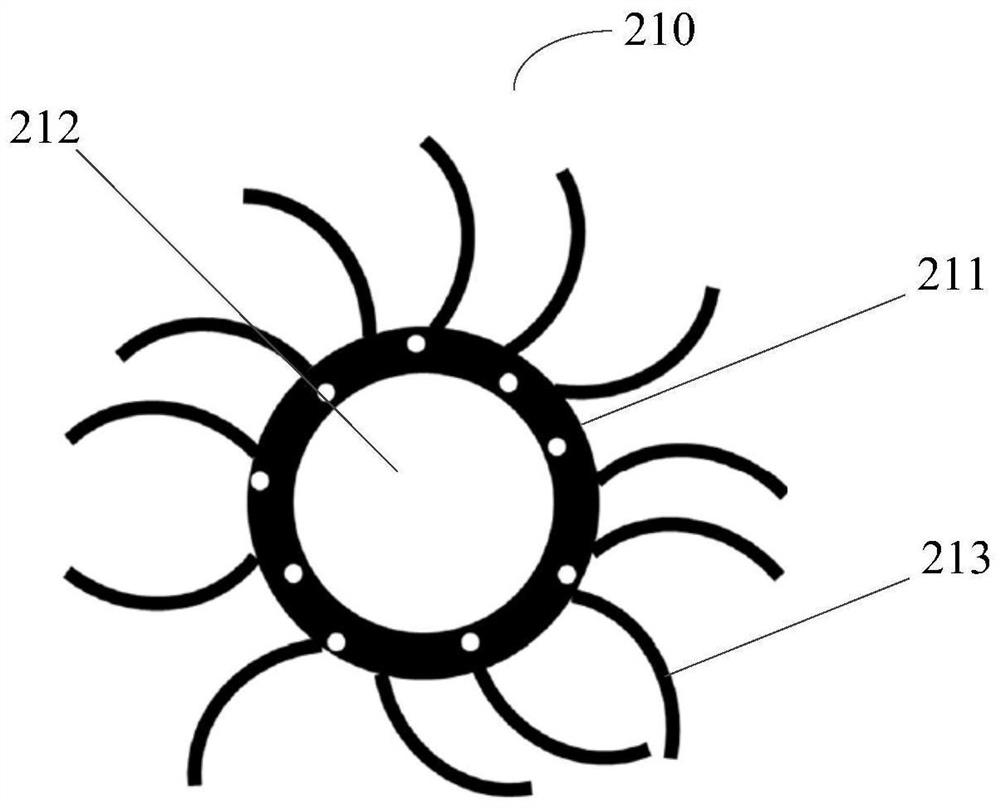

[0093] 1) Preparation of the first particle

[0094] Disperse 0.2g of iron ferric oxide nanoparticles (particle size is 150nm) in 140mL of absolute ethanol, add 2mL of ammonia water, 40mL of deionized water and surfactant, add 0.5mL of orthosilicon dropwise within 1 hour under the action of mechanical stirring Ethyl acetate, reacted at room temperature for 12 hours, obtained porous hybrid particles with ferric oxide core and silica shell;

[0095] Disperse the above-mentioned porous hybrid particles in a solvent containing 60mL of ethanol, 20mL of water, 1mL of ammonia water and 1mL of 3-aminopropyltriethoxysilane, mix well, and react at 80°C for 2 hours to obtain amino-modified porous hybrid particles;

[0096] Re-disperse the amino-modified porous hybrid particles in anhydrous chloroform, deoxygenate with nitrogen for 30 minutes, add triethylamine, stir evenly, place at 0°C and slowly add...

Embodiment 2

[0109] Embodiment 2, embodiment 2 can be made as Figure 4 Battery separator shown:

[0110] 1) Preparation of the first particle

[0111] Disperse 0.2g of iron ferric oxide nanoparticles (particle size is 150nm) in 140mL of absolute ethanol, add 2mL of ammonia water, 40mL of deionized water and surfactant, add 0.5mL of orthosilicon dropwise within 1 hour under the action of mechanical stirring Ethyl acetate, reacted at room temperature for 12 hours, obtained porous hybrid particles with ferric oxide core and silica shell;

[0112] Disperse the above-mentioned porous hybrid particles in a solvent containing 60mL of ethanol, 20mL of water, 1mL of ammonia water and 1mL of 3-aminopropyltriethoxysilane, mix well, and react at 80°C for 2 hours to obtain amino-modified porous hybrid particles;

[0113] Re-disperse the amino-modified porous hybrid particles in anhydrous chloroform, deoxygenate with nitrogen for 30 minutes, add triethylamine, stir evenly, place at 0°C and slowly ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com