A kind of graphene-based high thermal conductivity phase change material and preparation method and production device thereof

A phase change material, graphene-based technology, applied in heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc. The effect of improving the degree of wetting and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

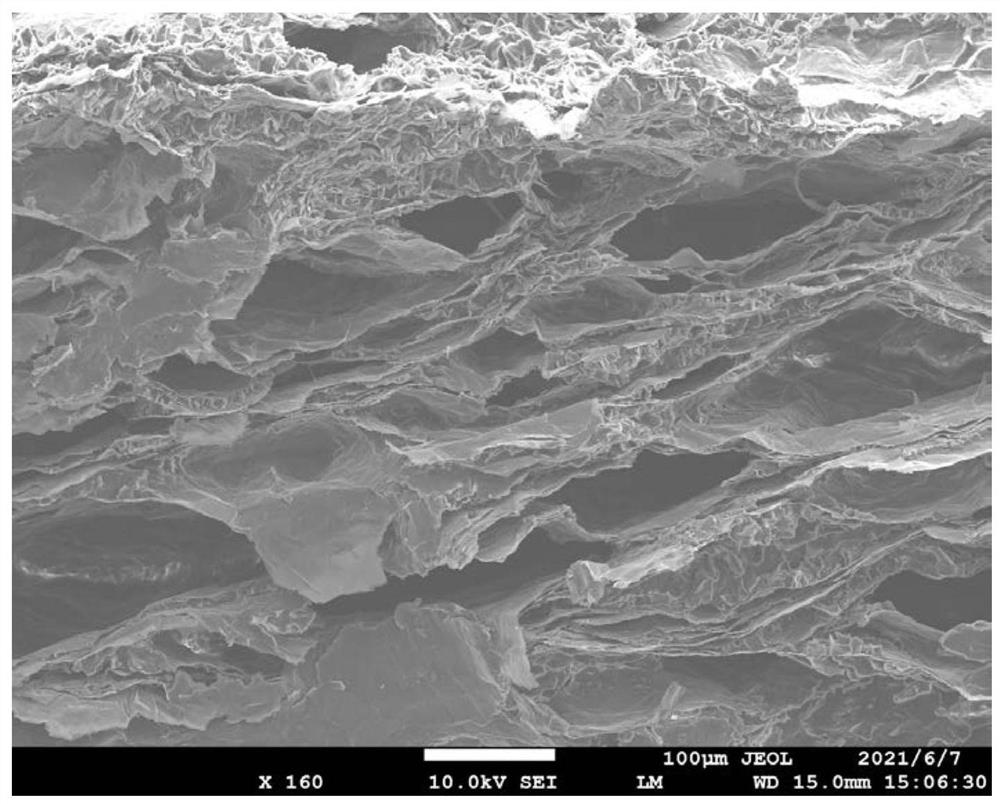

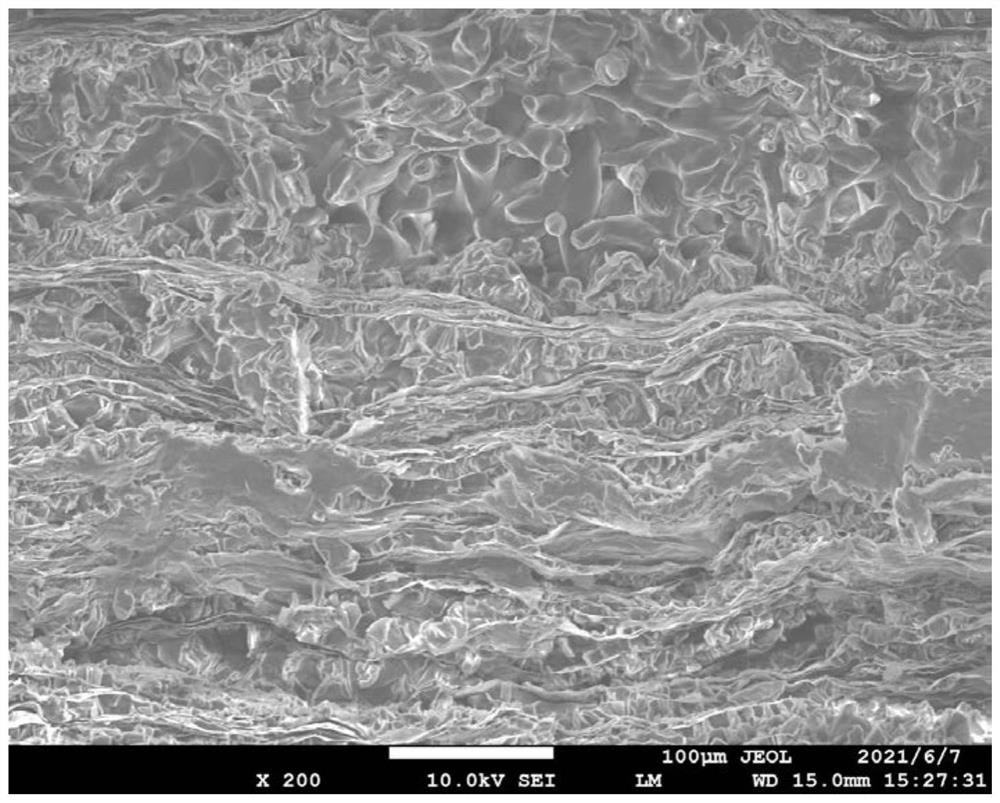

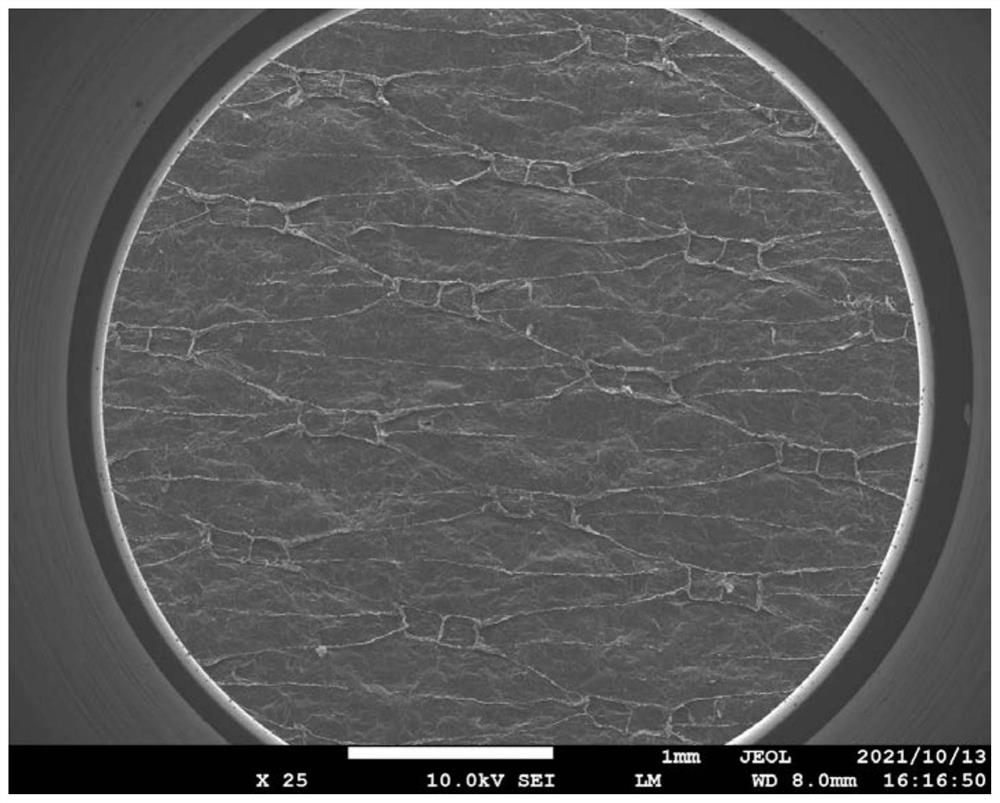

[0035] The preparation method of the graphene-based high thermal conductivity phase change material of the present embodiment includes the following steps: (1) setting the density to 0.3 g / cm 3 , the thickness is 5mm, the pore size is 0.001-300μm graphene foam, after the shielding film is attached to the surface, put it into the vacuum temperature change box 1, vacuumize, the vacuum degree is 90kPa, and the temperature is raised to 65 ℃; (2) The paraffin phase change material (phase change temperature 60 ° C) in the syringe 2, and heated to 65 ° C, until all the solid phase change materials become liquid phase change materials; (3) slowly pierce the injection port of the syringe 2 into the graphene foam, The depth of 2.5mm, slowly inject the liquid paraffin phase change material, stop injecting the phase change material immediately after the liquid overflows from the puncture port, and then quickly cool down the vacuum temperature change box 1 to 20 ℃, and keep the temperature ...

Embodiment 2

[0038] The preparation method of the graphene-based high thermal conductivity phase change material of the present embodiment includes the following steps: (1) adjusting the density to 0.3 g / cm 3 , the thickness is 5mm, the pore size is 0.001-300μm graphene foam, after the shielding film is attached to the surface, put it into the vacuum temperature change box 1, vacuumize, the vacuum degree is 133Pa, and the temperature is raised to 65 ℃; (2) The paraffin phase change material (phase change temperature 60 ° C) in the syringe 2, and heated to 65 ° C, until all the solid phase change materials become liquid phase change materials; (3) slowly pierce the injection port of the syringe 2 into the graphene foam, The depth of 2.5mm, slowly inject the liquid paraffin phase change material, stop injecting the phase change material immediately when the liquid overflows from the injection port, and then quickly cool down the vacuum temperature change box 1 to 20 ° C and keep it warm for 3...

Embodiment 3

[0040] The preparation method of the graphene-based high thermal conductivity phase change material of the present embodiment includes the following steps: (1) setting the density to 0.18g / cm 3, the thickness is 1mm, the pore size is 0.001-300μm graphene foam, after the shielding film is attached to the surface, it is put into the vacuum temperature change box 1, vacuumized, the vacuum degree is 133Pa, and the temperature is raised to 45 °C; (2) The paraffin phase change material (phase change temperature 40 ° C) in the syringe 2, and heated to 45 ° C, until all solid phase change materials are turned into liquid phase change materials; (3) the injection port of the syringe 2 is slowly pierced into the graphene foam, The depth of 0.5mm, slowly inject the liquid paraffin phase change material, stop injecting the phase change material immediately when the liquid overflows from the injection port, then quickly cool down the vacuum temperature change box 1 to 15 ℃, and keep the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com