Preparation method of vinegar

A vinegar and vinegar drench technology, applied in the field of vinegar, can solve the problems of low clarity, complicated process, long time, etc., and achieve the effects of improving purity and clarity, improving fermentation efficiency, and improving degree of infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of vinegar comprises the steps:

[0053] Step 1. Raw material preparation:

[0054] Wash the glutinous rice and then steam it once, then drain the steamed glutinous rice for later use; in the cooking process, after cooking thoroughly in a pressure cooker, then cook at a high temperature of 60° C. for 0.5 h.

[0055] Step two, mixing:

[0056] The drained glutinous rice and bran were mixed and refrigerated for later use to obtain a mixture; the weight ratio of the glutinous rice and bran was 1:0.7, the refrigerated temperature was -5°C, and refrigerated for 1 hour.

[0057] Step three, infiltration:

[0058] Add water to the mixed material obtained in step 2, soak thoroughly and swell to obtain a sizing; the soaking time is 20 hours, and the amount of soaking water accounts for 70% of the mass of the mixed material.

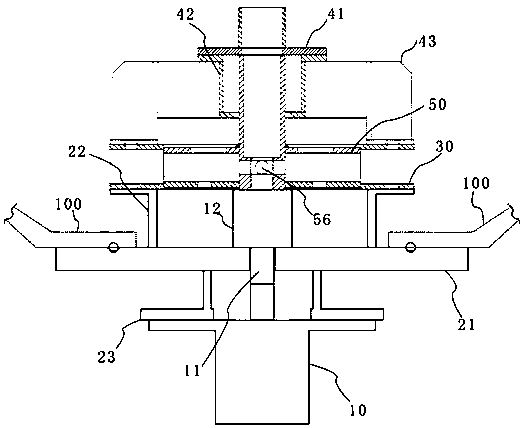

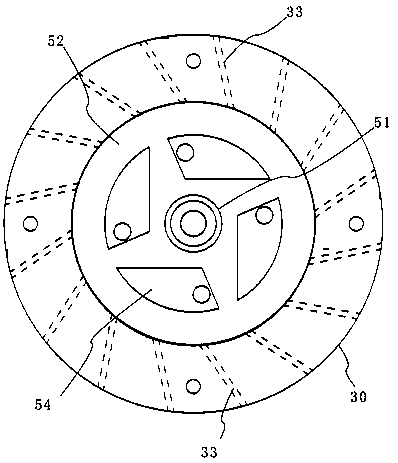

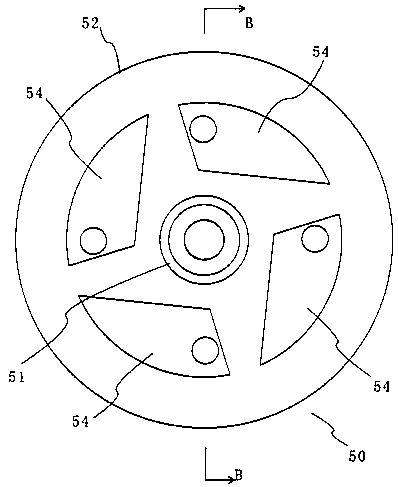

[0059] Among them, the infiltration is carried out in the infiltration tank, and the mixture and water are added to the infiltrat...

Embodiment 2

[0083] The preparation method of vinegar comprises the steps:

[0084] Step 1. Raw material preparation:

[0085] After the glutinous rice is washed, it is steamed once, and then the steamed glutinous rice is drained for later use; during the steaming process, after being thoroughly cooked in a pressure cooker, it is then steamed at a high temperature of 62° C. for 0.5 h.

[0086] Step two, mixing:

[0087] The drained glutinous rice and bran were mixed and refrigerated for later use to obtain a mixture; the weight ratio of the glutinous rice and bran was 1:0.8, the refrigerated temperature was -4°C, and refrigerated for 1.1 h.

[0088] Step three, infiltration:

[0089] Water is added to the mixed material obtained in step 2, and the soaked material is obtained after soaking thoroughly and swelling; the soaking time is 21 hours, and the amount of soaking water accounts for 75% of the mass of the mixed material.

[0090] Among them, the infiltration is carried out in the in...

Embodiment 3

[0104] The preparation method of vinegar comprises the steps:

[0105] Step 1. Raw material preparation:

[0106] Wash the glutinous rice and then steam it once, then drain the steamed glutinous rice for later use; during the steaming process, after the steaming in the pressure cooker is thoroughly cooked, it is then steamed at a high temperature of 68° C. for 0.8 hours.

[0107] Step two, mixing:

[0108] The drained glutinous rice and bran were mixed and refrigerated for later use to obtain a mixture; the weight ratio of the glutinous rice and bran was 1:0.7, the refrigerated temperature was -3°C, and refrigerated for 1.3 hours.

[0109] Step three, infiltration:

[0110] Water is added to the mixed material obtained in step 2, and the soaked material is obtained after thoroughly infiltrating and swelling; the soaking time is 23 hours, and the amount of soaking water accounts for 85% of the mass of the mixed material.

[0111] Among them, the infiltration is carried out in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com