Preparation method and system of high-toughness thermosetting resin-based prepreg

A thermoplastic resin and thermosetting technology, applied in the field of materials, can solve the problems of composite material stability and poor internal quality, and achieve the effect of solving preparation problems and improving the degree of infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

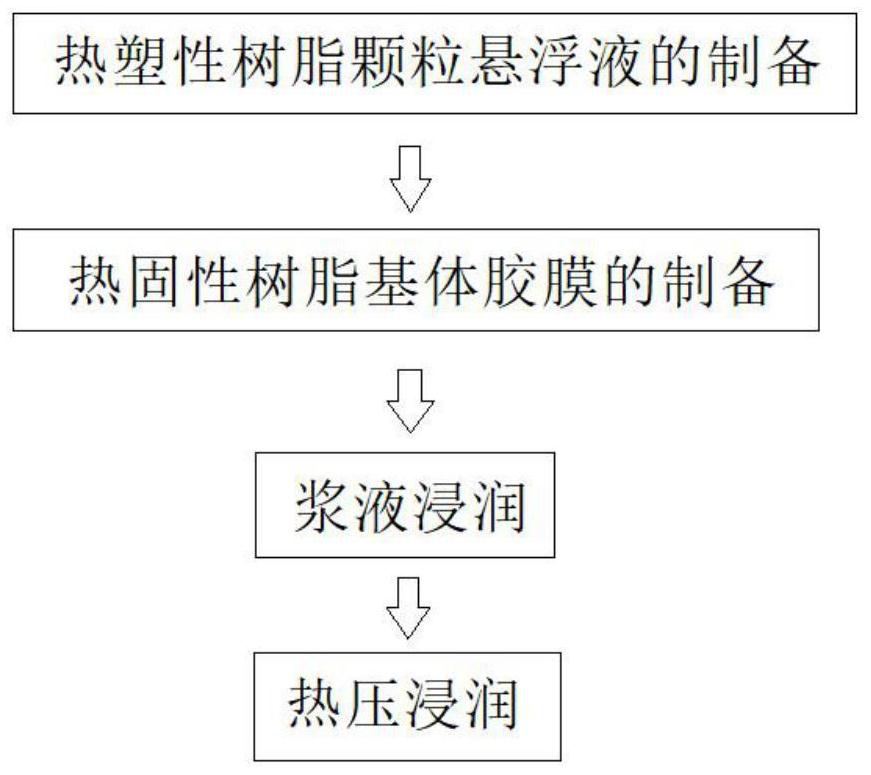

[0030] Such as image 3 As shown, the preparation method of the high toughness thermosetting resin-based prepreg provided by the invention comprises the following steps:

[0031] Preparation of thermoplastic resin particle suspension: disperse thermoplastic resin particles used for toughening in a poor solvent to obtain thermoplastic resin particle suspension;

[0032] Preparation of thermosetting resin matrix adhesive film: heating and mixing the thermosetting resin matrix components to form a homogeneous resin matrix, and coating to form a thermosetting resin matrix adhesive film;

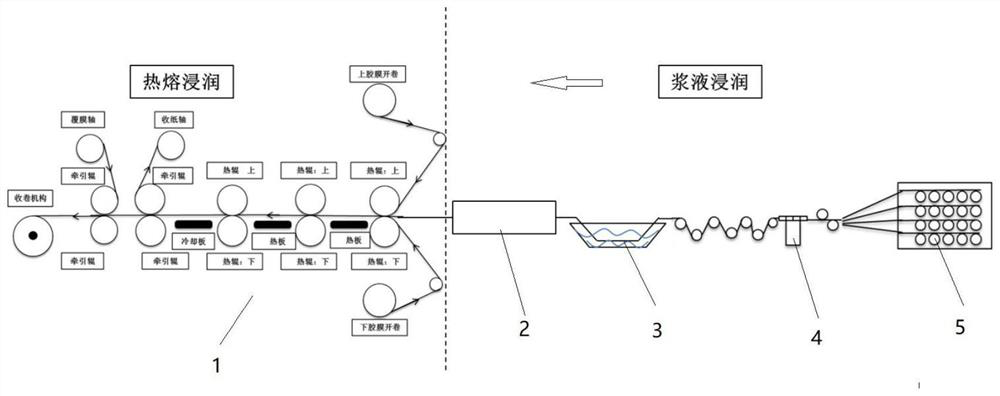

[0033] Slurry infiltration: soak the reinforcement material into the thermoplastic resin particle suspension and dry it to obtain the reinforcement material after the dry slurry infiltration;

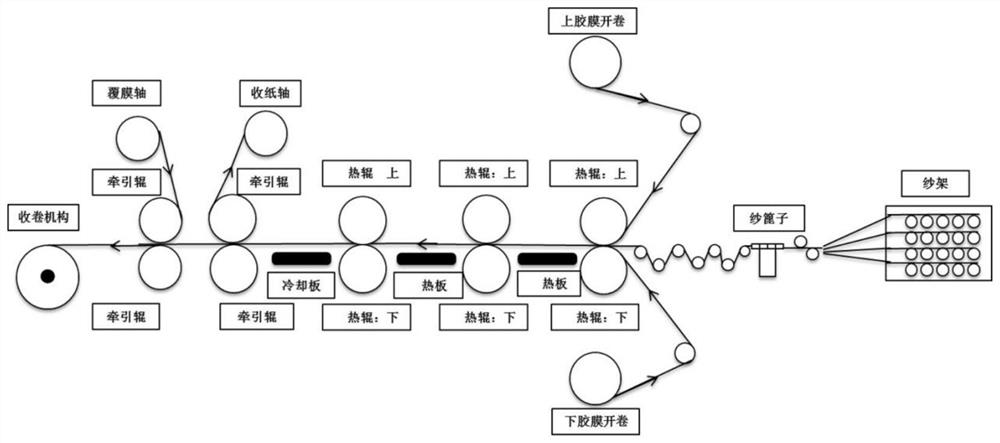

[0034] Hot-press infiltration: Pull the reinforcing material soaked in the dry slurry into the hot-melt prepreg machine, and heat-press infiltrate with the thermosetting resin matrix film to obtain a ther...

Embodiment 1

[0047] Preparation of modified bismaleimide resin prepreg reinforced with thermoplastic polyimide resin:

[0048] The thermoplastic polyimide resin particles were dispersed in water using a planetary disperser, and the thermoplastic polyimide suspension was obtained by vigorously dispersing, with a solid content of 20%. Use a film machine to coat the modified bismaleimide resin matrix into a film, and the surface density of the film is 25g / m 2 . Install the 280-axis carbon fiber on the creel and pull it to the traction roller for production. Start the prepreg machine, the carbon fiber first goes through the yarn spreading and then enters the slurry tank, is evenly impregnated with the thermoplastic polyimide suspension, and then enters the high-temperature oven to dry the water in the suspension. Then the carbon fiber enters the hot-melt prepreg part, and the upper and lower adhesive films are covered on the carbon fiber. Under the heat and pressure of multiple pairs of hot ...

Embodiment 2

[0051] Preparation of modified bismaleimide resin prepreg toughened by thermoplastic polyaryletherketone resin:

[0052] The thermoplastic polyaryletherketone resin particles were dispersed in ethanol using a planetary disperser, and the thermoplastic polyimide suspension was obtained by strong dispersion, with a solid content of 16%. Use a film machine to coat the modified epoxy amine resin matrix into a film, and the surface density of the film is 33g / m 2 . Install the 120-axis carbon fiber on the creel and pull it to the traction roller for production. Start the prepreg machine, the carbon fiber first goes through the yarn spreading and then enters the slurry tank, is evenly impregnated with the thermoplastic polyimide suspension, and then enters the high-temperature oven to dry the water in the suspension. Then the carbon fiber enters the hot-melt prepreg part, and the upper and lower adhesive films are covered on the carbon fiber. Under the heat and pressure of multiple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com