Fuel cell plate forming method based on expanded graphite

A fuel cell electrode plate and expanded graphite technology, applied in fuel cells, circuits, electrical components, etc., can solve problems affecting mass production scale, and achieve the effects of pipeline operation, good air permeability and conductivity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

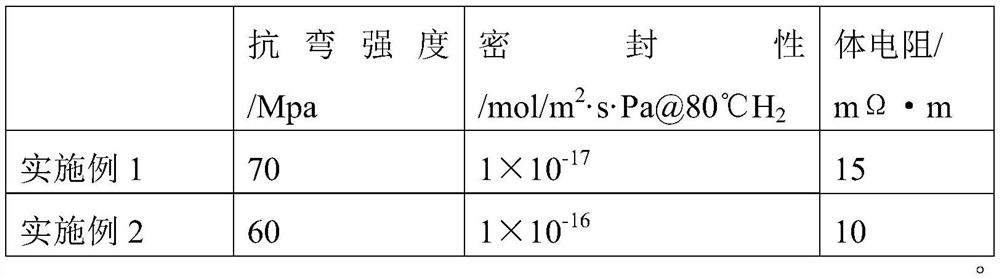

Examples

Embodiment 1

[0023] A fuel cell polar plate forming method based on expanded graphite, comprising the following steps:

[0024] (1) Powder vacuum impregnation: Put the raw material powder of the graphite plate of the fuel cell into the reactor, evacuate and maintain it for 10-30 minutes, inject liquid resin without releasing the vacuum, so that the raw material powder can be completely submerged; pressurize to Maintain 0.5-1MPa for 8-12 minutes, and then release the pressure to obtain "wet material" for use; the raw material of the fuel cell graphite plate is conventional graphite plate formula fuel, and the graphite powder used is worm graphite powder.

[0025] (2) Plate making: the wet material is extruded through a filter press to form an expanded graphite plate, and excess resin will also be squeezed out to reduce the resin content in the plate;

[0026] (3) Cutting and molding: the expanded graphite plate obtained in step (2) is divided into the size required by the fuel cell pole pla...

Embodiment 2

[0029] A fuel cell polar plate forming method based on expanded graphite, comprising the following steps:

[0030] (1) Powder vacuum impregnation: Put the raw material powder of the graphite plate of the fuel cell into the reactor, evacuate and maintain it for 10-30 minutes, inject the liquid resin without releasing the vacuum, so that the raw material powder can be completely submerged, and mix thoroughly The vacuum is released to obtain "wet material" for later use; the raw material of the fuel cell graphite plate is conventional graphite plate formula fuel, and the graphite powder used is worm graphite powder.

[0031] (2) Plate making: the wet material is extruded into expanded graphite plates by rolling to control the thickness, during which excess resin will also be squeezed out to reduce the resin content in the plate;

[0032] (3) Cutting and molding: the expanded graphite plate obtained in step (2) is divided into the size required by the fuel cell pole plate using a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com