Formula food for special medical purposes based on novel mixing mode and preparation method thereof

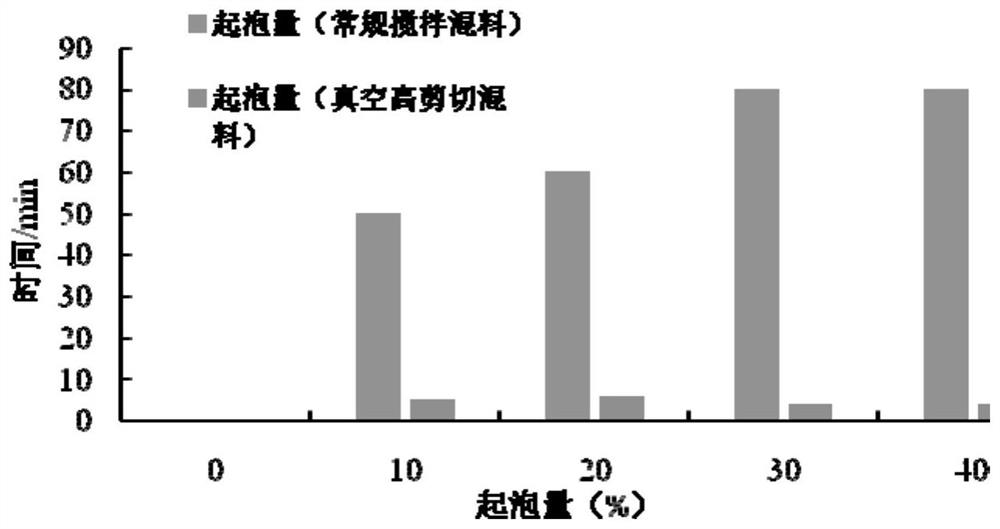

A formula food and material mixing technology, which is applied in food ingredients, food drying, food forming, etc., can solve the problems of air bubbles, long stirring time, and reduced mixing effect, so as to prevent material oxidation, improve infiltration degree, and improve mixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

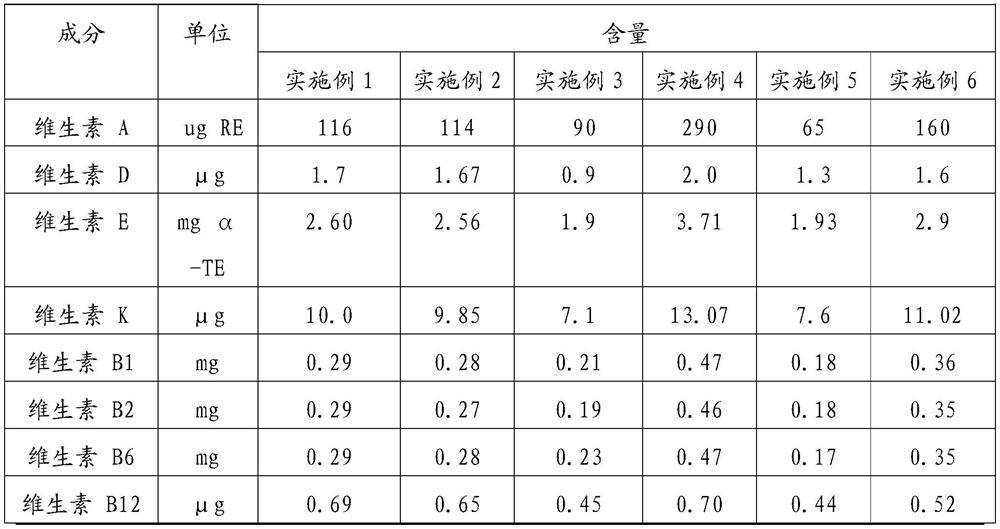

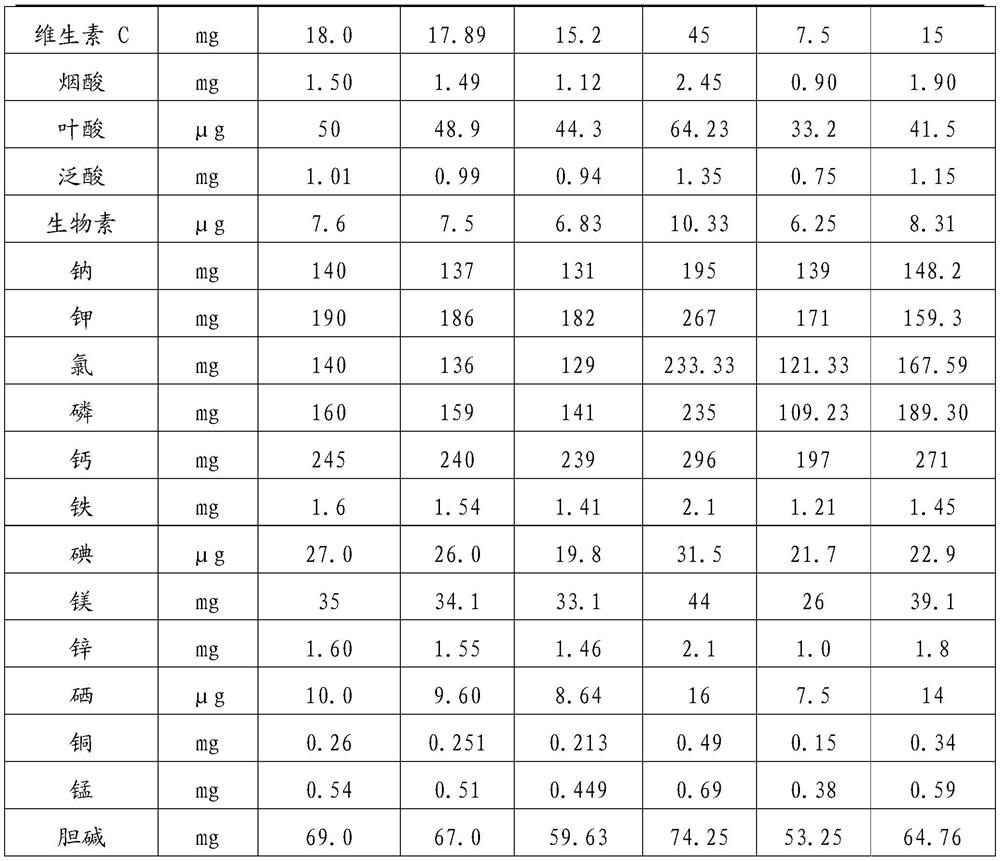

[0031] 1) Raw material preparation: 85g protein, 50g fat, 160g carbohydrate, 1.728g multivitamin, 9.64g multimineral, 1.8g essence and 691g water;

[0032] The protein comprises 25g of whey protein concentrate, 30g of casein, and 30g of milk protein isolate;

[0033] Described fat comprises coconut oil 15g, sunflower oil 15g, rapeseed oil 9g, medium chain triglyceride 9g, lecithin 2g;

[0034] Described carbohydrate comprises maltodextrin 125g and sucrose 35g;

[0035] Said 1 portion of multivitamins contains 1.2mg of vitamin A, 18ug of vitamin D, 35mg of vitamin E, 150ug of vitamin K, and 150ug of vitamin B 1 4mg, vitamin B 2 4mg, vitamin B 6 4mg, vitamin B 12 7.5ug, vitamin C 350mg, niacin 15mg, folic acid 600ug, pantothenic acid 13mg, biotin 90ug, choline 700mg;

[0036] Said 1 portion of compound minerals contains 1500mg of sodium, 2000mg of potassium, 1500mg of chlorine, 1700mg of phosphorus, 2500mg of calcium, 17mg of iron, 280ug of iodine, 400mg of magnesium, 1...

Embodiment 2

[0054] Example 2: The difference between Example 2 and Example 1 is that the method for preparing the formula food for special medical purpose based on the new mixing method in step 3 is a conventional stirring method. That is, step 3) comprises the following steps:

[0055] ① Dissolve the protein and carbohydrate raw materials in the formula amount in the mixer with water at 55-65°C, pay attention to feeding and mixing slowly, and try to avoid a large amount of foam. If there is a large amount of foam, the upper layer of foam should be removed;

[0056] ②Proceed to step ① and mix the composite mineral microspheres with water at the same time, and add the mixed composite mineral microspheres into the mixing tank of step ①, and stir together, and pay attention to the stirring speed not being too fast;

[0057] ③ Carry out step ① and heat and mix the fat at the same time, the temperature is 45-65°C, then add it into the mixing tank of step ①, stir together, and carry out pre-emu...

Embodiment 3

[0066] Example 3: The only difference between Example 3 and Example 1 is that step 3) in the method of preparing the formula food for special medical use based on the new mixing method, the multivitamin microspheres and the multimineral microspheres are not added, but directly added Multivitamins and multiminerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com