Glue brushing process for camera accessory

A technology for cameras and accessories, applied in electrical components, image communication, color TV components, etc., can solve problems such as insufficient, adhesive layer deformation, complex research, etc., to increase the density of contact points, improve the degree of wetting, and improve the roughness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

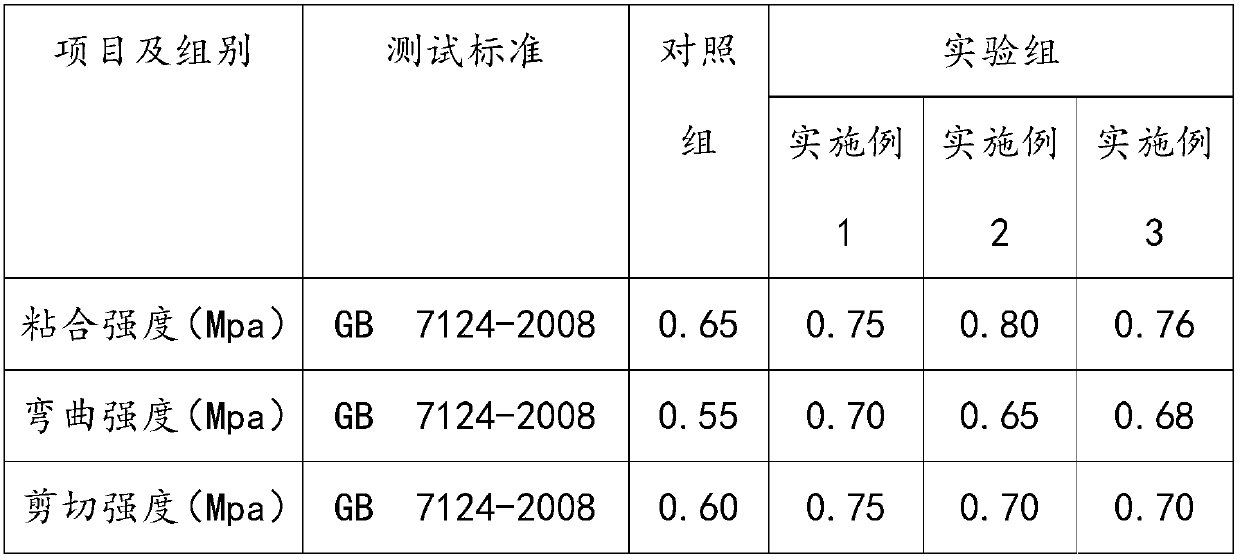

Embodiment 1

[0020] A glue brushing process for camera accessories, comprising the following steps:

[0021] 1) Wipe the glued parts of the camera accessories and the parts glued to the glued parts of the camera accessories with 96% alcohol for 5 times, then use absorbent paper to wipe off the residual alcohol, and finally use a hair dryer to dry the above parts Air-dry, and control the hot air temperature of the hair dryer to 60°C, and the air-drying time to 170s;

[0022] 2) Grinding the surface of the glued parts of the camera accessories treated in step 1) and the parts glued to the glued parts of the camera accessories with a grinder to roughen the surface to increase its surface energy and increase Bonding area, so as to improve the later adhesive strength;

[0023] 3) Use compressed air to remove debris from the surface of the glued parts of the camera accessories treated in step 2) and the parts glued to the glued parts of the camera accessories, and then put acetone, methyl ethyl...

Embodiment 2

[0029] A glue brushing process for camera accessories, comprising the following steps:

[0030] 1) Wipe the glued parts of the camera accessories and the parts glued to the glued parts of the camera accessories with 90% alcohol for 3 times, then use absorbent paper to wipe off the residual alcohol, and finally use a hair dryer to dry the above parts Air-dry, and control the hot air temperature of the hair dryer to 50°C, and the air-drying time to 150s;

[0031] 2) Grinding the surface of the glued parts of the camera accessories treated in step 1) and the parts glued to the glued parts of the camera accessories with a grinder to roughen the surface to increase its surface energy and increase Bonding area, so as to improve the later adhesive strength;

[0032] 3) Use compressed air to remove debris from the surface of the glued parts of the camera accessories treated in step 2) and the parts glued to the glued parts of the camera accessories, and then mix acetone, n-hexane and...

Embodiment 3

[0038] A glue brushing process for camera accessories, comprising the following steps:

[0039] 1) Wipe the glued parts of the camera accessories and the parts glued to the glued parts of the camera accessories with 93% alcohol for 4 times, then use absorbent paper to wipe off the residual alcohol, and finally use a hair dryer to dry the above parts Air-dry, and control the hot air temperature of the hair dryer to 55°C, and the air-drying time to 160s;

[0040] 2) Grinding the surface of the glued parts of the camera accessories treated in step 1) and the parts glued to the glued parts of the camera accessories with a grinder to roughen the surface to increase its surface energy and increase Bonding area, so as to improve the later adhesive strength;

[0041] 3) Use compressed air to remove debris from the surface of the glued parts of the camera accessories treated in step 2) and the parts glued to the glued parts of the camera accessories, and then press methyl ethyl ketone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com