Method for prolonging service life of cylindrical lithium-ion battery

A lithium-ion battery, cylindrical technology, applied in the field of improving the life of cylindrical lithium-ion batteries, can solve the problems of battery cycle life impact, incomplete activation, etc., to achieve the effect of improving life, uniform distribution, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

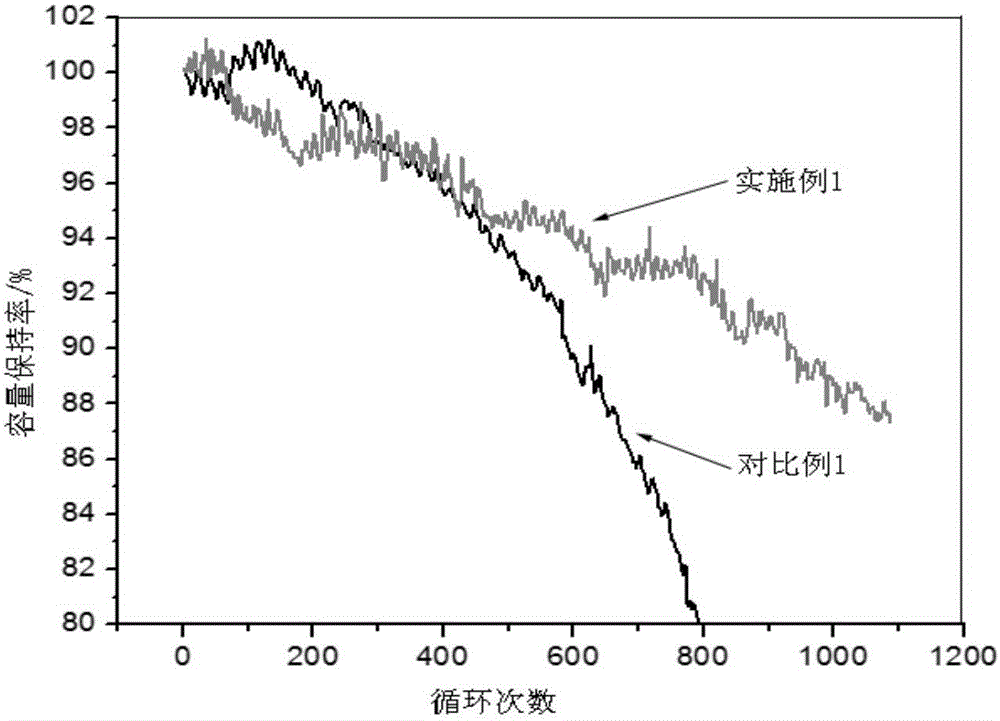

[0021] (1) Produce ternary material / graphite batteries according to the normal process. In this example, it refers specifically to 18650 cylindrical batteries. The thermometer tests the surface temperature of the battery. When the surface temperature of the battery reaches 35°C, charge and discharge 10 times in the range of 3.2-4.1V with a current of 0.2C;

[0022] (2) Then put the battery at room temperature, wait until the temperature of the battery drops to room temperature, charge the battery with a constant current of 1C to a voltage of 4.2V, and the charge cut-off current is 0.02C, and then discharge it with a constant current of 1C, the discharge cut-off voltage is 3.0V, cycle performance test results are as attached in the manual figure 1 shown.

Embodiment 2

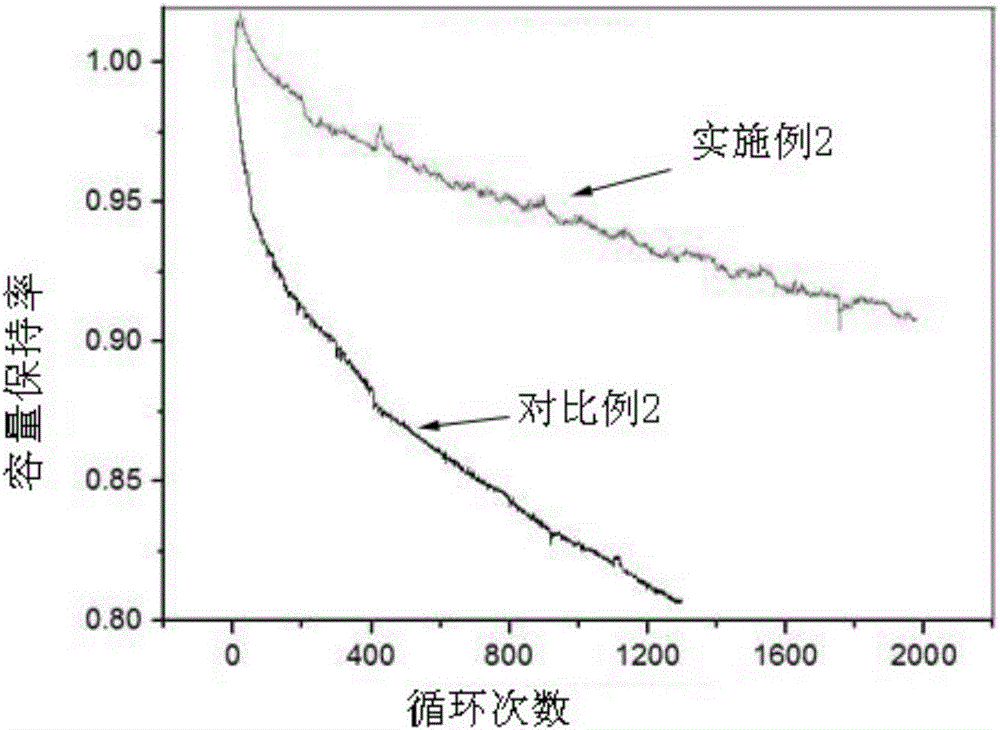

[0027] (1) Produce lithium iron phosphate / graphite batteries according to the normal process. In this example, it refers specifically to 18650 cylindrical batteries. The thermometer tests the surface temperature of the battery. When the surface temperature of the battery reaches 40°C, charge and discharge 15 times in the range of 2.5-3.4V with a current of 0.3C;

[0028] (2) Then put the battery at room temperature, charge it to 3.65V with a constant current of 1C, the charge cut-off current is 0.02C, and then discharge it with a constant current of 1C, the discharge cut-off voltage is 2.0V, the cycle performance test results are as attached in the manual figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com