Device and method for production of long-fiber-reinforced thermoplastic resin

A technology that enhances thermoplasticity and production equipment. It is applied in the field of polymer material production. It can solve problems such as process difficulties and achieve the effects of expanding the selection range, easy dispersion and disintegration, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

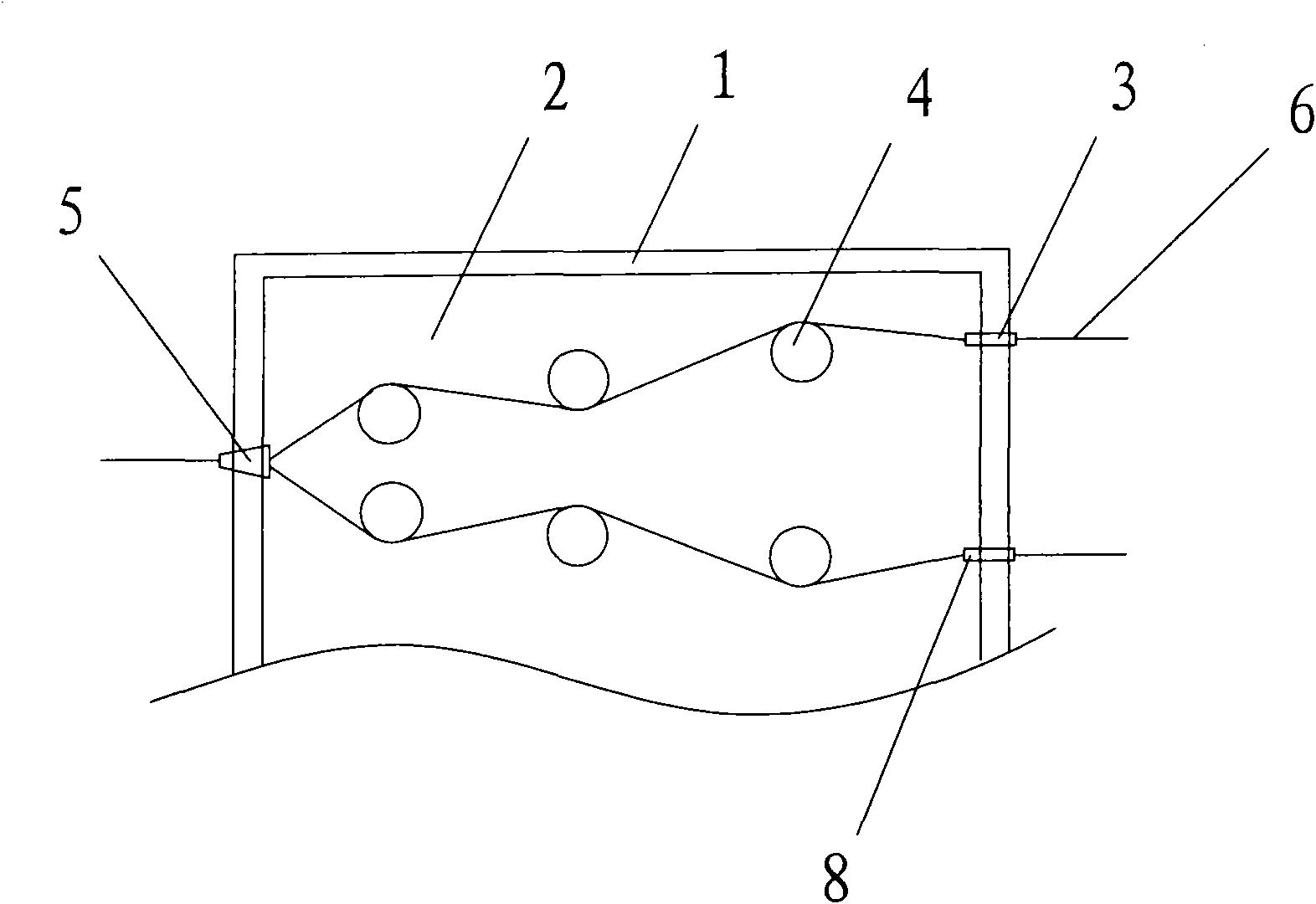

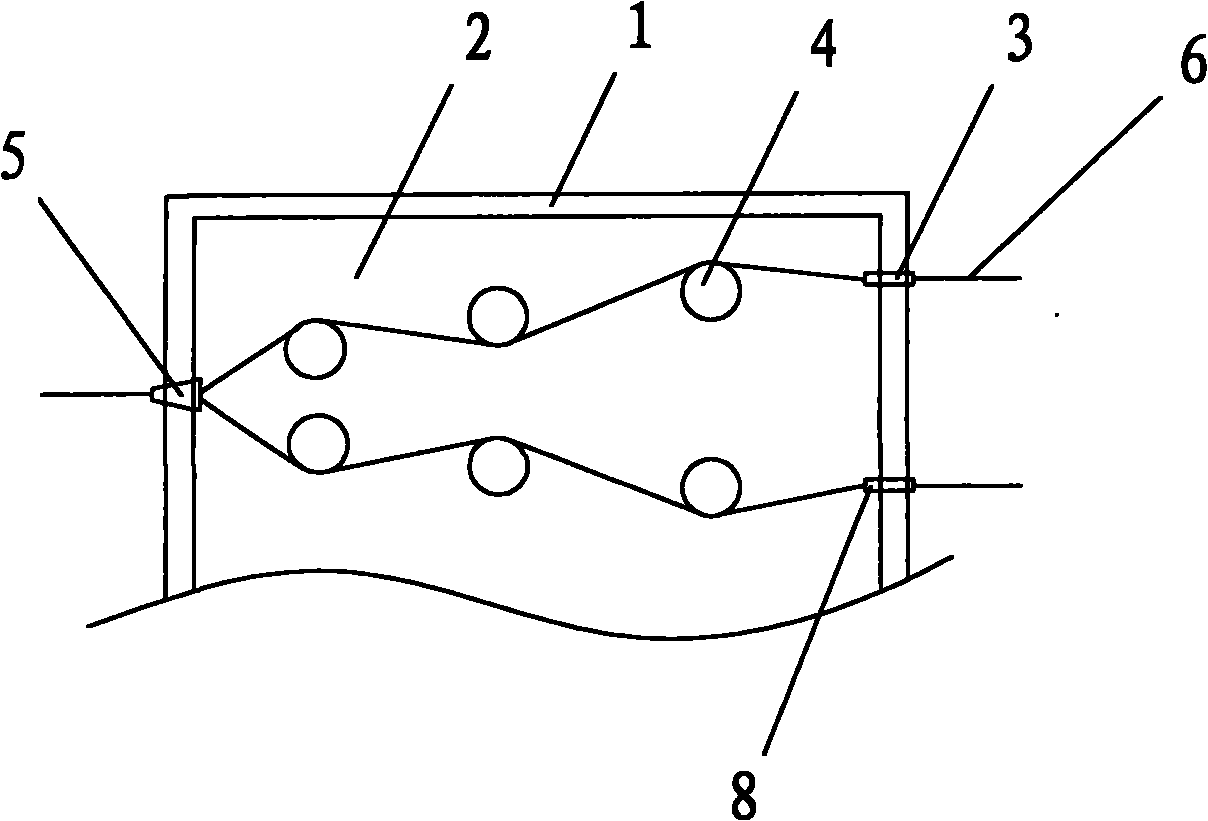

[0031] Such as figure 1 As shown, a long-fiber-reinforced thermoplastic resin production device of the present invention includes a melt impregnation chamber 1, the melt impregnation chamber contains a resin melt 2 for impregnating fibers, and a side wall of the melt impregnation chamber 1 is provided with There are two fiber bundle inlets 3, the fiber bundle inlet 3 has a protrusion 8 extending into the melt impregnation chamber, the middle of the fiber bundle inlet 3 has a round hole or an elliptical hole or a through hole of other shapes, and the fiber bundle enters from the round hole or ellipse Through the hole, a fiber bundle outlet 5 is provided on the side wall of the melt impregnation chamber 1 opposite to the side wall where the fiber bundle inlet is arranged. The fiber bundle outlet 5 is in the shape of a bell mouth, with a through hole in the middle, and the fiber bundle outlet 5. The opening on one side of the melt impregnation chamber is larger than the opening o...

Embodiment 2

[0038] On the basis of Embodiment 1, a plurality of tension rollers 4 are arranged in the melt impregnation chamber 1, and each strand of fiber bundles entering the melt impregnation chamber 1 passes through the surfaces of a plurality of tension rollers 4 respectively, and the tension rollers 4 are opposite to the fibers. The bundle generates tension. When each fiber bundle passes through each set of tension rollers, it disperses and disintegrates according to the degree of tension, so that the fiber bundles are unfolded, become dispersed, and form a fiber belt. A bundle of fibers to be impregnated is divided into several strands , the linear density of the fiber bundle is reduced, the fiber bundle with low linear density is easier to disperse and disintegrate, the number of layers of the formed fiber tape is less, the resin melt is more likely to impregnate into the fiber tape, and the degree of impregnation is improved. The surface of the tension roller may be curved. The s...

Embodiment 3

[0043] Two fiber bundle inlets 3 are provided on a side wall of the melt impregnation chamber 1, and a fiber bundle outlet 5 is provided on the side wall opposite to the side wall where the fiber bundle inlet is provided in the melt impregnation chamber 1, and two fiber bundle outlets are provided. The bundle inlets 3 are arranged at the same height of the side walls, one fiber bundle inlet is at the left side of the side wall, the other is at the right side of the side wall, and the fiber bundle outlet 5 is arranged at the same height of the opposite side wall, horizontally The upper position is set on the perpendicular bisector of the line connecting the two fiber bundle inlets. The sum of the cross-sectional areas of the through holes of the two fiber bundle inlets 3 is less than or approximately equal to the cross-sectional area of the opening of the fiber bundle outlet 5 on the side of the melt impregnation chamber.

[0044] A plurality of tension rollers 4 may be provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com