Method for preparing bicycle frame from long-fiber reinforced thermoplastic composite material through on-line direct molding

A technology of composite materials and bicycle racks, which is applied to household components, household appliances, and other household appliances. It can solve the problems of low elastic rate and rigidity, large quality differences, and insufficient strength of aluminum, and achieve low cost, light weight, and Good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

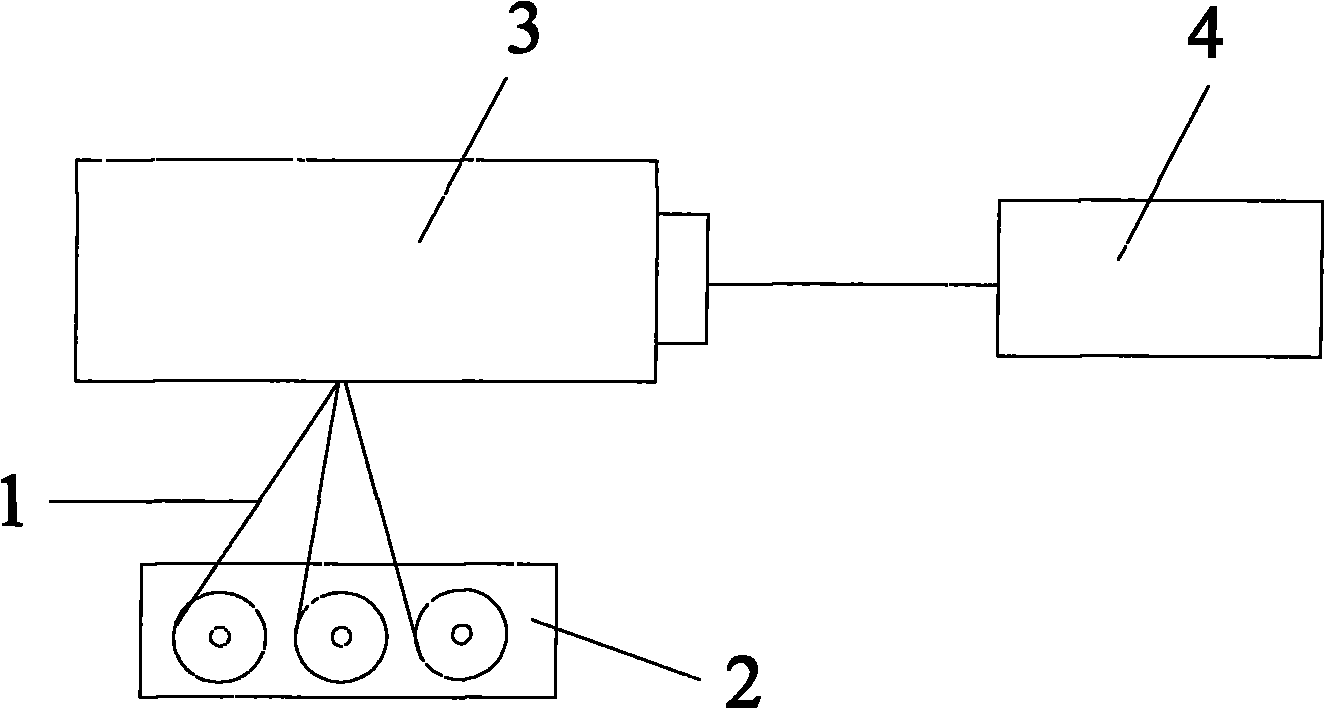

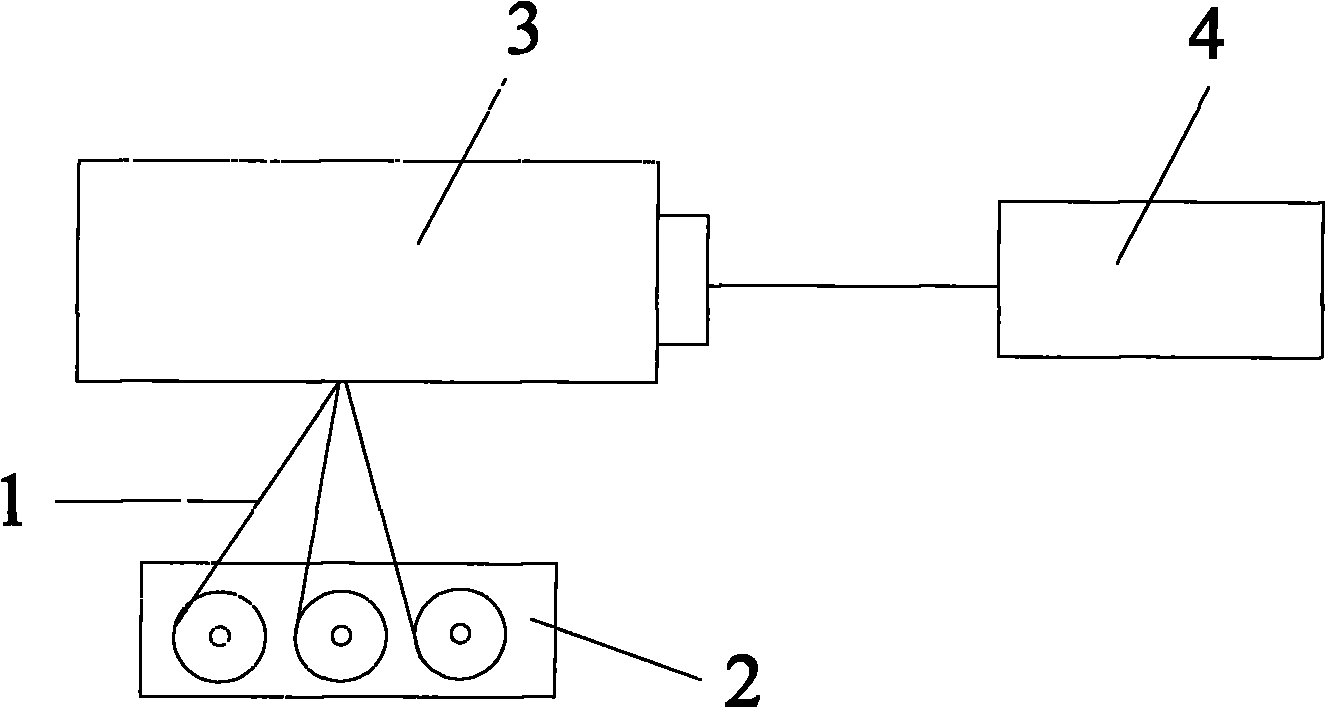

[0035] A kind of long fiber reinforced thermoplastic composite material online direct forming (LFT-D forming) manufactures the method for bicycle frame, manufacturing device such asfigure 1 As shown, the method includes the following steps:

[0036] (1) The processing temperature is controlled to be 230-250°C, and nylon 6 resin and additives are plasticized in the barrel of twin-screw extruder 3 at a weight ratio of 1:0.35, wherein the additives are antioxidants 1098 and 168, and The mixture of maleic anhydride grafted polypropylene and polyethylene wax as lubricant, the weight ratio is 1:1:5:1;

[0037] (2) The continuous glass fiber 1 is drawn out from the creel 2, and after being adjusted and dispersed by the tension roller, it is introduced into the barrel of the twin-screw extruder 3 from the middle section of the twin-screw extruder 3, and cut by the screw, the continuous glass fiber is uniform Mixed into the melt of nylon 6 resin, the weight ratio of continuous glass fi...

Embodiment 2

[0040] A kind of long fiber reinforced thermoplastic composite material on-line direct forming (LFT-D molding) manufactures the method for bicycle frame, and this method comprises the following steps:

[0041] (1) Control the processing temperature to 180-200°C, plasticize homopolypropylene resin and additives in the barrel of a twin-screw extruder at a weight ratio of 1:0.17, wherein the additives are antioxidants 1010 and 168, A mixture of compatibilizer glycidyl methacrylate and polypropylene copolymer, the weight ratio of which is 0.4:0.1:12;

[0042] (2) The continuous polyethylene terephthalate fiber is drawn out from the creel, and after the tension is adjusted and dispersed by the tension roller, it is introduced into the barrel of the twin-screw extruder from the middle section of the twin-screw extruder, cut by the screw, and continuously The polyethylene terephthalate fiber is evenly mixed into the homopolypropylene resin melt, and the weight ratio of the continuous...

Embodiment 3

[0045] A kind of long fiber reinforced thermoplastic composite material on-line direct forming (LFT-D molding) manufactures the method for bicycle frame, and this method comprises the following steps:

[0046] (1) The processing temperature is controlled to be 300-320°C, and the polycarbonate resin and additives are plasticized in the barrel of a twin-screw extruder at a weight ratio of 1:0.5, wherein the additives are antioxidants 1076 and 168, horse A mixture of toric anhydride grafted polyethylene and PE color masterbatch, the weight ratio of which is 0.1:0.3:10:20;

[0047] (2) The continuous stainless steel fiber is drawn from the creel, and after the tension is adjusted by the tension roller, it is introduced into the barrel of the twin-screw extruder from the middle section of the twin-screw extruder, and the continuous stainless steel fiber is evenly mixed into the polycarbonate by cutting the screw. In the resin melt, the weight ratio of the continuous stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com