Unit extensible type assembled metal gutter and manufacturing and installing method thereof

An installation method, telescopic technology, applied in building structure, roofing, construction, etc., can solve problems such as heavy assembly, riveting or welding workload, waterproof, drainage performance cannot be guaranteed, low processing and installation efficiency, etc., to achieve environmental protection The comprehensive social benefits of energy saving are large, the waterproof and drainage quality performance is reliable, and the effect of reducing gutter maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

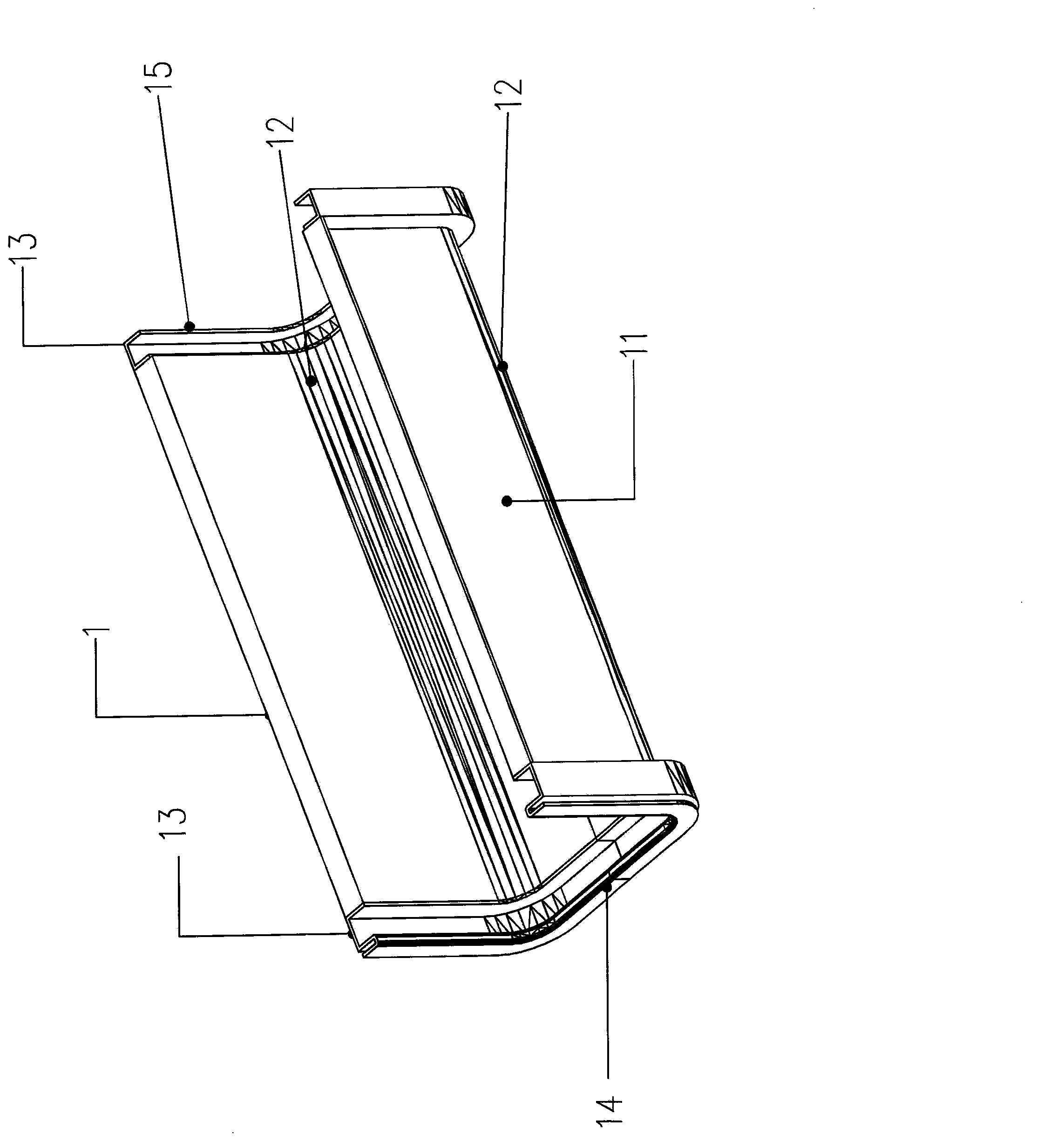

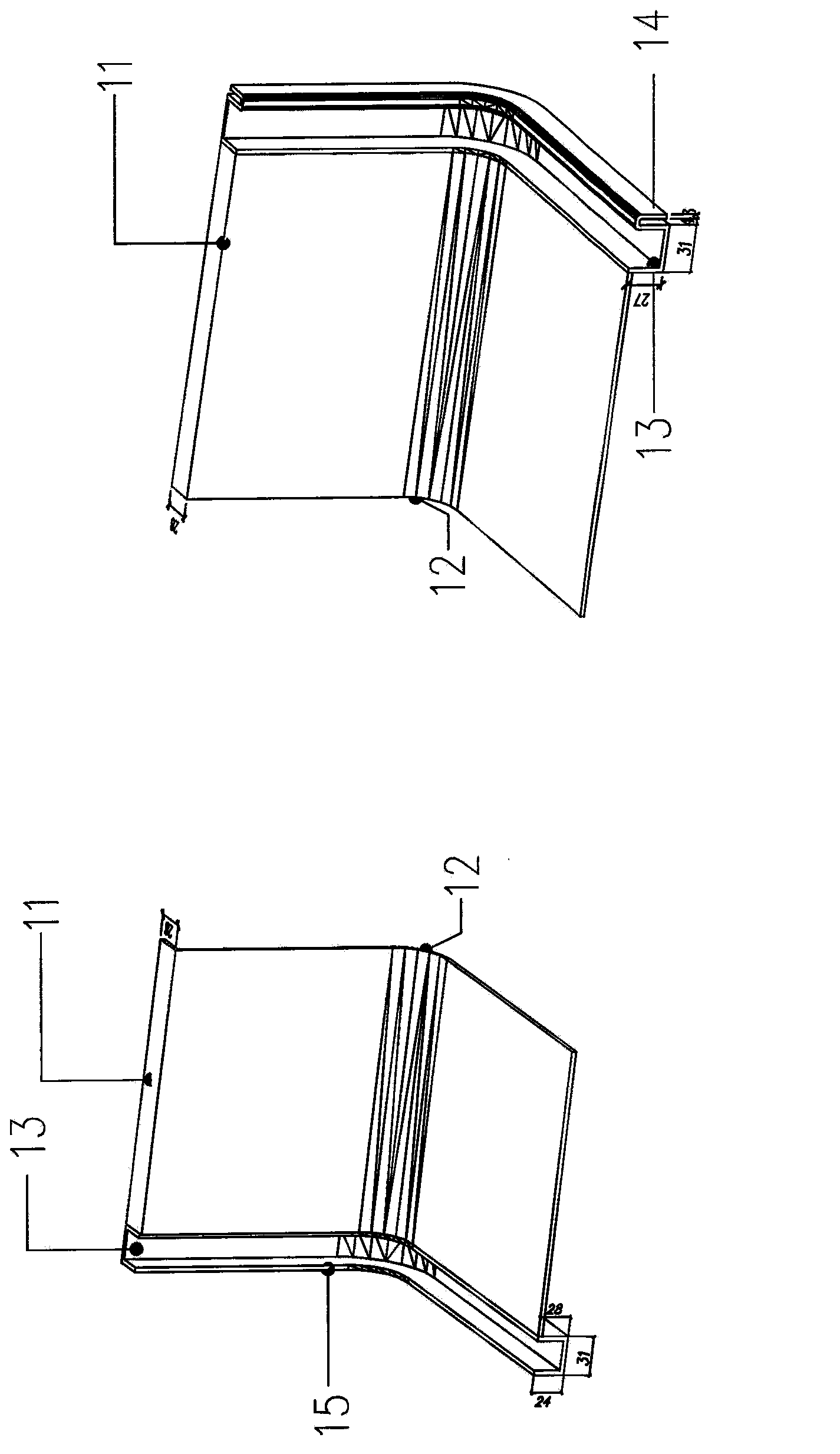

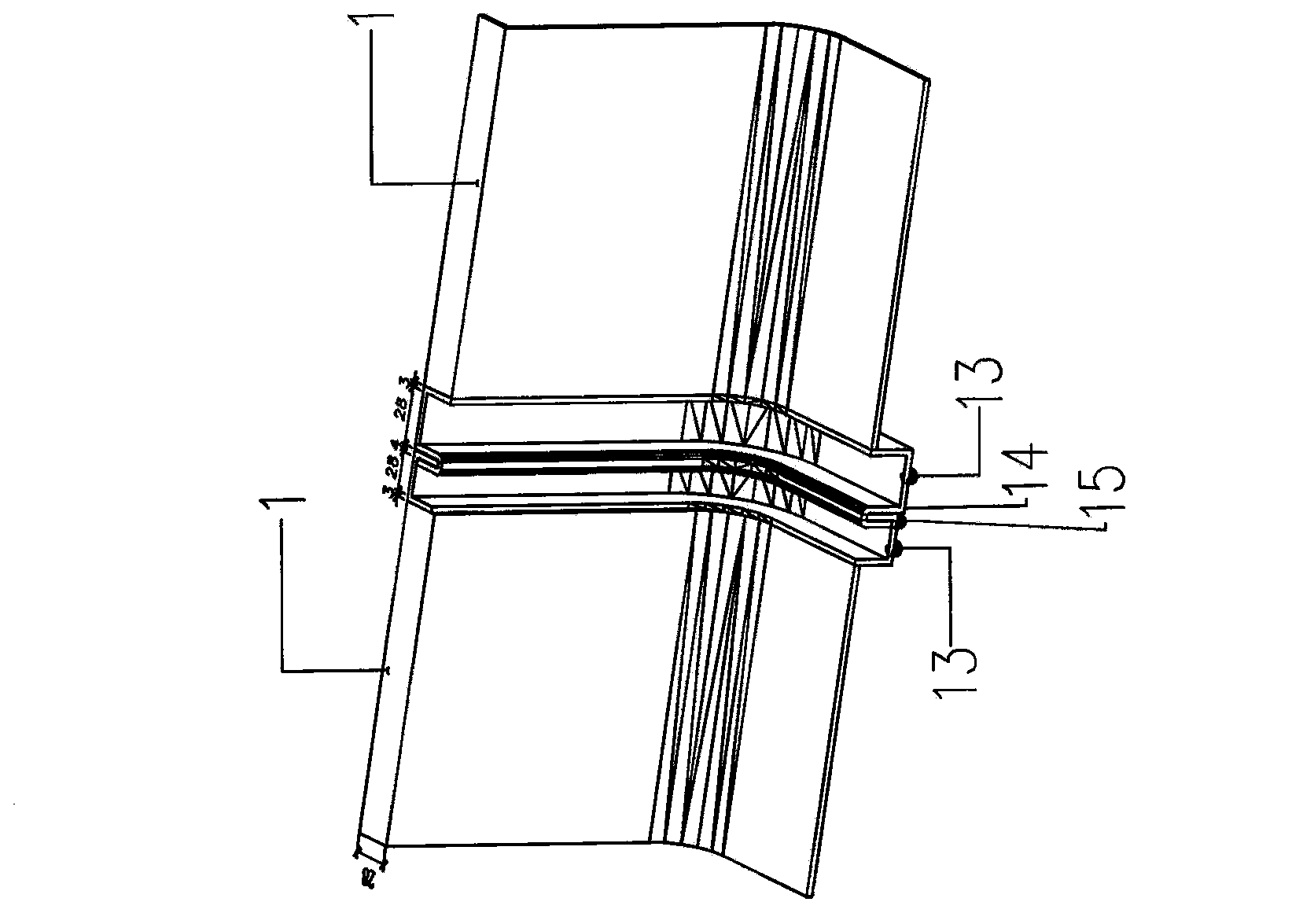

[0045] Such as figure 1 with figure 2 As shown, a unit telescopic assembled metal gutter includes several gutter unit segments 1, and each gutter unit segment 1 includes a U-shaped gutter body segment 11 made of metal plate and a metal skeleton 12. Two square steel metal skeletons 12 are arranged on the bottom of the type sky ditch body section 1 and the corner part of the side wall on the outside, and a connection structure connected with the building is arranged on the metal skeleton 12; The ports at both ends of the body section 11 are integrally provided with a transverse U-shaped groove telescopic interface part 13, and the outside of the transverse U-shaped groove telescopic structure part provided at both ends of the U-shaped gutter body is provided with a matching buckle structure. The details of the buckle structure are:

[0046] On the outer side wall of the U-shaped gutter body section 11 made of metal plate, a folded plate part is extended outwards on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com