Long glass fiber reinforced polypropylene resin engine skid plate of passenger vehicle

A polypropylene resin and long glass fiber technology, applied in the direction of deflectors, etc., can solve the problems of unsatisfactory weight reduction, cost reduction, material recyclability, narrow recycling range, and bulky parts, etc., so as to save procurement materials and plate preheating process, light weight, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

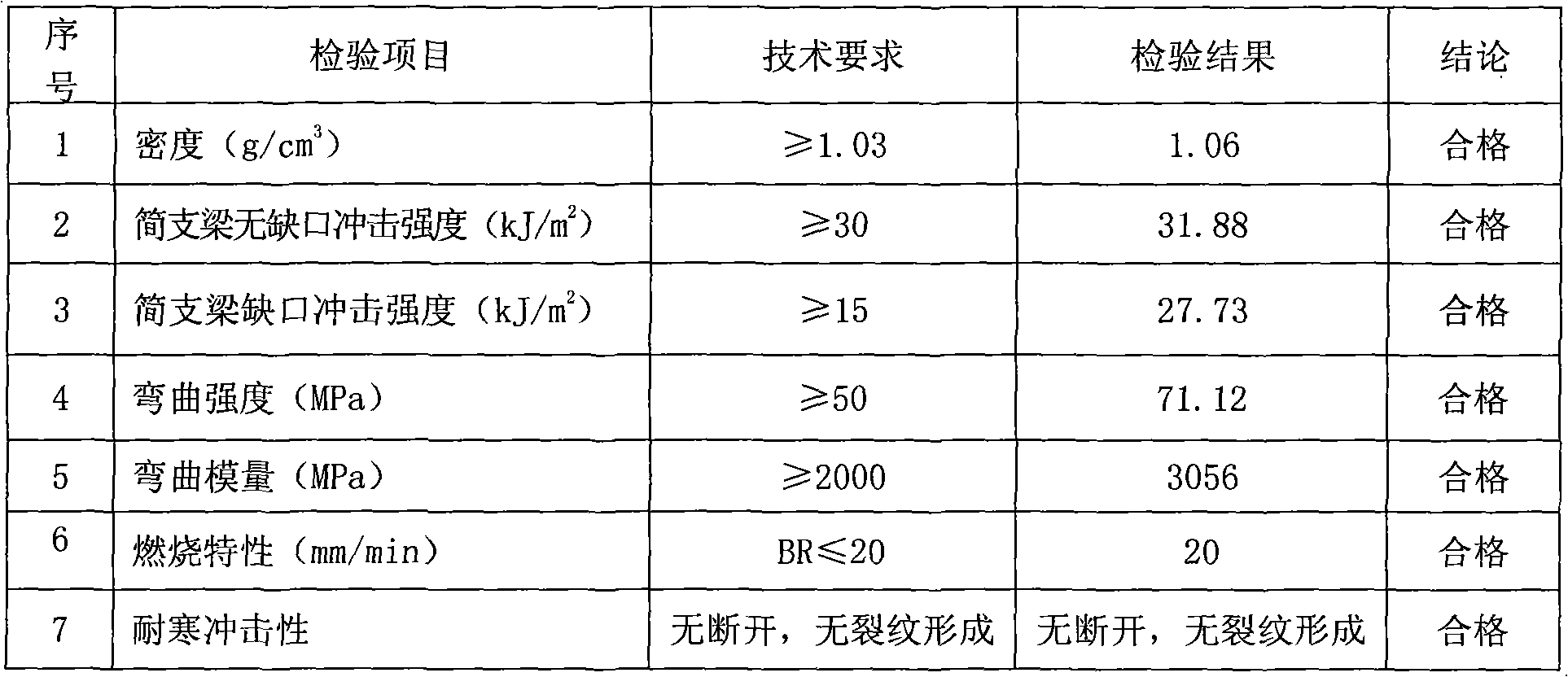

Examples

Embodiment 1

[0018] First, polypropylene: 78, glass fiber: 22, weigh and prepare materials according to parts by weight, and extrude long glass fiber reinforced polypropylene resin (LFT) through a general-purpose extruder at an extrusion temperature of 115°C.

[0019] According to the shape and size of the bottom guard plate, the weight and size of the required LFT sheet are calculated, and the long glass fiber reinforced polypropylene resin LFT molten sheet code material is directly cut from the extrusion port of the specific extruder.

[0020] Then put the cut long glass fiber reinforced polypropylene resin LFT molten sheet into the mold according to the predetermined method. Once placed, the mold is closed immediately, the mold temperature is normal temperature, the mold pressure is 22MPa, the holding time is 18sec, and the molding cycle is 40sec. In order to prevent product deformation, the product just out of the mold should be placed reasonably, if necessary, it can be placed on a si...

Embodiment 2

[0022] First, polypropylene: 75, glass fiber: 25, weigh and prepare materials according to parts by weight, and extrude long glass fiber reinforced polypropylene resin (LFT) through a general-purpose extruder at an extrusion temperature of 249°C.

[0023] According to the shape and size of the bottom guard plate, the weight and size of the required LFT sheet are calculated, and the long glass fiber reinforced polypropylene resin LFT molten sheet code material is directly cut from the extrusion port of the specific extruder.

[0024] Then put the cut long glass fiber reinforced polypropylene resin LFT molten sheet into the mold according to the predetermined method. Once placed, the mold is closed immediately, the mold temperature is normal temperature, the mold pressure is 22MPa, the holding time is 18sec, and the molding cycle is 40sec. In order to prevent product deformation, the product just out of the mold should be placed reasonably, if necessary, it can be placed on a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com