A safety shoe protective toecap made of a long fiber reinforced thermoplastic resin composite material and a preparing method thereof

A resin composite material and enhanced thermoplastic technology, which is applied to reinforcements, shoe uppers, footwear, etc., can solve the problems of reducing the impact performance of parts, safety shoe weight, poor insulation, etc., achieve good impact performance, solve poor insulation, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Mix 100 parts of PP, 0.1 part of antioxidant 1010, 0.7 part of coupling agent KH550, and 0.2 part of lubricant silicone powder in a high-speed mixer for 3 minutes, and mix well.

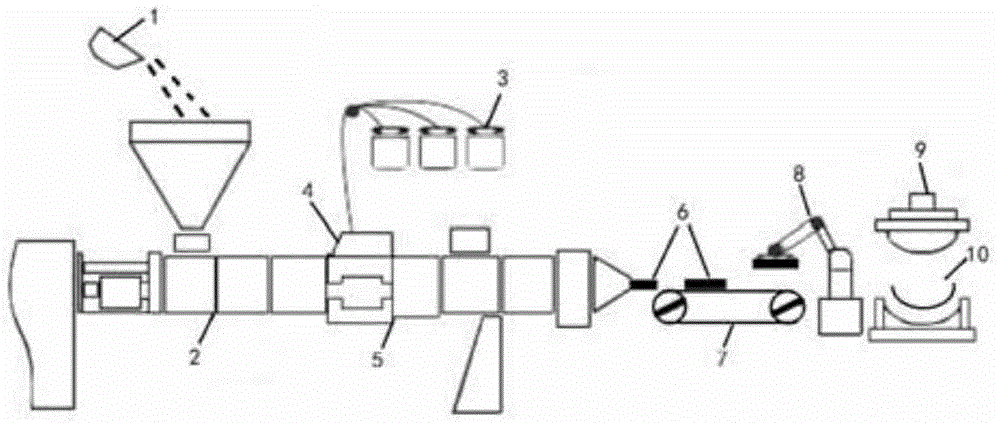

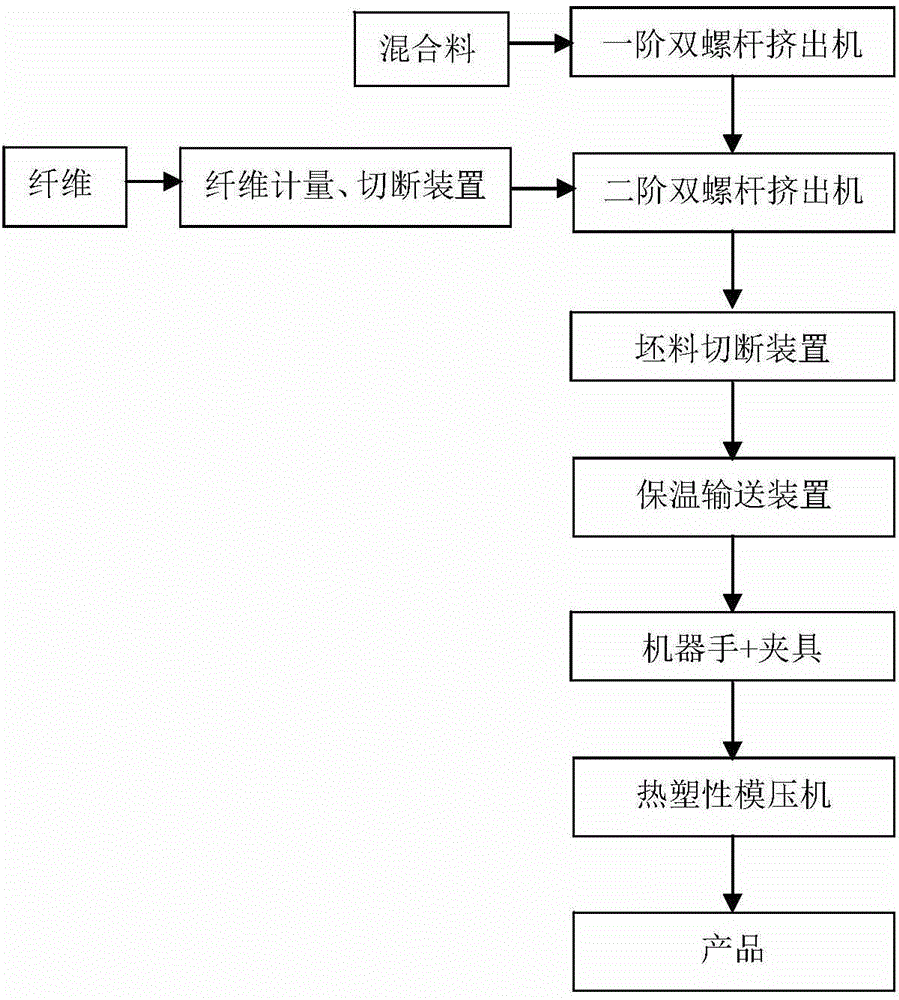

[0039] (2) Mix material 1 in (1) according to figure 1 or image 3 As shown in the flow chart, through the first-stage twin-screw extruder 2, melting, mixing, and extrusion, the molten resin directly enters the opening 4 of the second-stage twin-screw extruder through a die head, and 300 parts of glass fiber roving 3 are also made This opening 4 is introduced, and through procedures such as cutting and dispersing, the glass fiber with a cutting length of 50mm is gently mixed into the pre-melted polymer through twin-screws, and then extruded.

[0040] Among them, the melt extrusion temperature of the first-stage twin-screw extruder is: 160°C in the first zone, 175°C in the second zone, 195°C in the third zone, 210°C in the fourth zone, 220°C in the fifth zone, and 220°C at the head; the se...

Embodiment 2

[0044] (1) Mix 100 parts of PA6, 0.2 parts of antioxidant 168, 0.5 parts of coupling agent KH560, and 0.4 parts of lubricant TAF in a high-speed mixer for 4 minutes, and mix well;

[0045] (2) Mix material 1 in (1) according to figure 1 or image 3As shown in the flowchart, the first-stage twin-screw extruder 2 is melted, mixed, and extruded, and the molten resin directly enters the opening 4 of the second-stage twin-screw extruder through a die head, and 233 parts of glass fiber roving 3 are also made of This opening 4 is introduced, and through procedures such as cutting and dispersing, the glass fiber with a cut length of 45mm is gently mixed into the pre-melted polymer through twin-screws, and then extruded.

[0046] Among them, the melt extrusion temperature of the first-stage twin-screw extruder is: 195°C in the first zone, 215°C in the second zone, 230°C in the third zone, 240°C in the fourth zone, 245°C in the fifth zone, and 245°C at the head; the second-stage twin-s...

Embodiment 3

[0050] (1) Mix 100 parts of PA66 and 0.3 parts of antioxidant 1076, 1.0 parts of coupling agent KH570, and 0.6 parts of lubricant RH-313 in a high-speed mixer for 5 minutes, and mix well;

[0051] (2) Mix material 1 in (1) according to figure 1 or image 3 As shown in the flowchart, through the first-stage twin-screw extruder 2, melting, mixing, and extrusion, the molten resin directly enters the opening 4 of the second-stage twin-screw extruder through a die head, and 212 parts of glass fiber roving 3 are also made of This opening 4 is introduced, and through procedures such as cutting and dispersing, the glass fiber with a cut length of 40 mm is gently mixed into the pre-melted polymer through twin-screws, and then extruded.

[0052] The melt extrusion temperature of the first-stage twin-screw extruder is: 225°C in the first zone, 245°C in the second zone, 265°C in the third zone, 275°C in the fourth zone, 280°C in the fifth zone, and 280°C at the head; The machine melt ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com