Filament-reinforced thermoplastic resin composition

A technology for strengthening thermoplastic and resin compositions, applied in the field of long-fiber reinforced thermoplastic resin compositions, can solve problems such as difficulty in maintaining mechanical strength, and achieve the effects of excellent fluidity and excellent balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

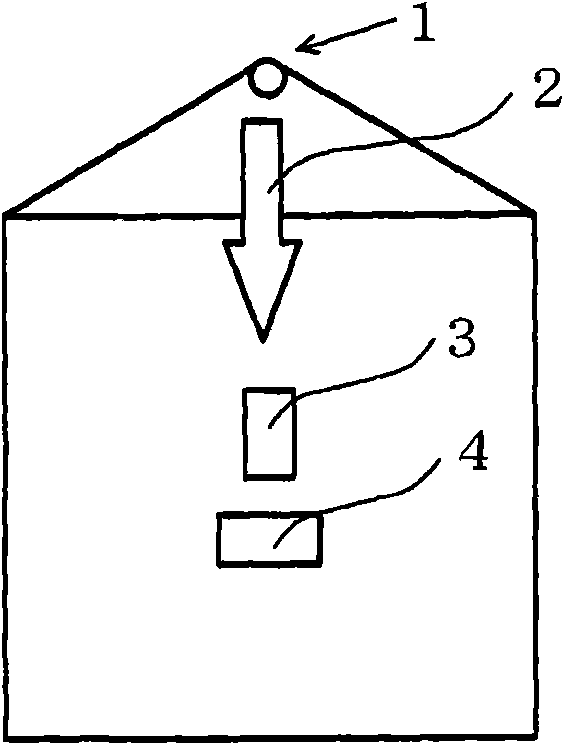

Method used

Image

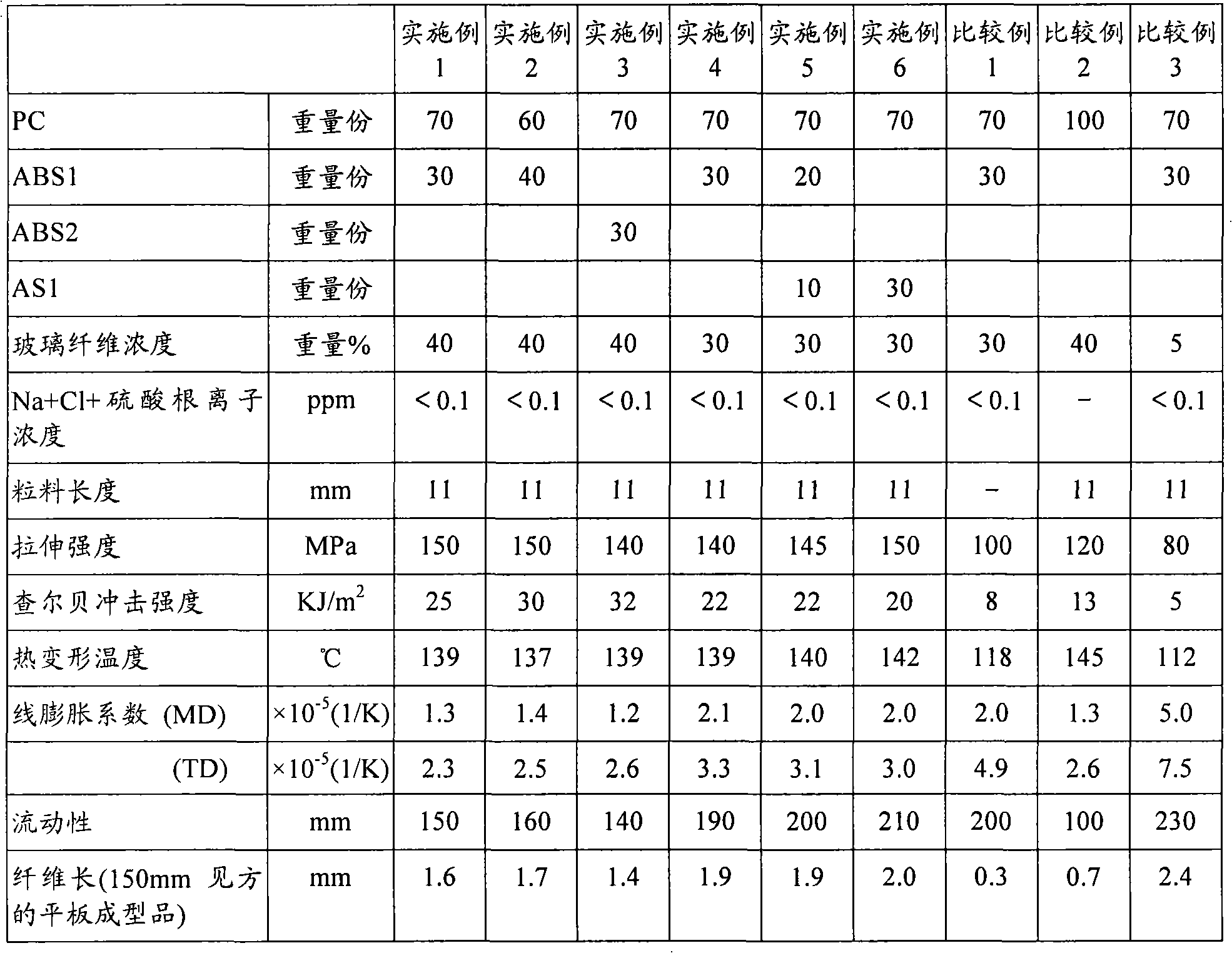

Examples

Embodiment 1

[0100] The glass fiber roving is drawn through a right-angle head that processes the passage of the continuous fiber into a wave shape, and at the same time, 70 parts by weight of PC as a thermoplastic resin in a molten state (280° C.) is supplied from an extruder connected to the right-angle head. and 30 parts by weight of ABS1, the resin is impregnated in glass fibers, then pulled out into strips through a shaping die, cooled, and cut to obtain pellets with a glass fiber content of 40% by weight and a length of 11mm . The obtained pellets were formed into samples for measurement of various physical properties by injection molding.

Embodiment 2

[0102] The glass fiber roving is drawn through a right-angle head that processes the passage of the continuous fiber into a wave shape, and at the same time, 60 parts by weight of PC as a thermoplastic resin in a molten state (280° C.) is supplied from an extruder connected to the right-angle head. and 40 parts by weight of ABS1, the resin is impregnated in glass fibers, then pulled out into strips through a shaping die, cooled, and cut to obtain pellets with a glass fiber content of 40% by weight and a length of 11 mm . The obtained pellets were formed into samples for measurement of various physical properties by injection molding.

Embodiment 3

[0104] The glass fiber roving is drawn through a right-angle head that processes the passage of the continuous fiber into a wave shape, and at the same time, 70 parts by weight of PC as a thermoplastic resin in a molten state (280° C.) is supplied from an extruder connected to the right-angle head. and 30 parts by weight of ABS2, after the resin is impregnated in glass fibers, it is pulled out into strips through a shaping die, and after cooling, it is cut to obtain pellets with a glass fiber content of 40% by weight and a length of 11 mm. . The obtained pellets were formed into samples for measurement of various physical properties by injection molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com