Plant fiber impregnation device and method

A plant fiber and impregnation device technology, which is applied in the field of plant fiber impregnation devices and plant fiber impregnation molten resin reinforcement materials, can solve the problems of poor impregnation effect, fiber tow breakage, unsuitable for natural fibers, etc., and achieve the effect of improving the impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

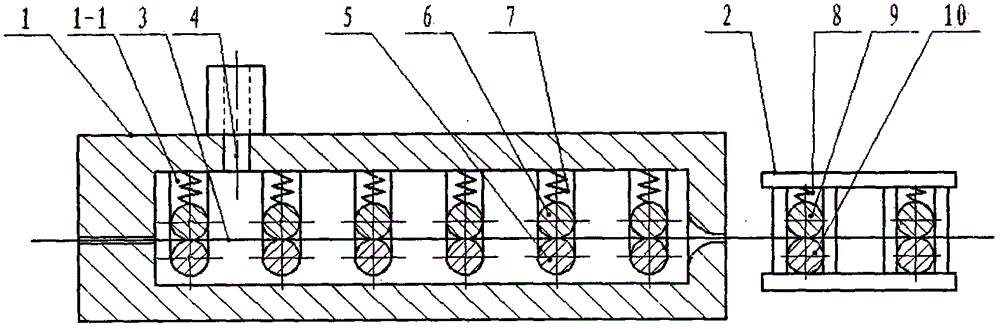

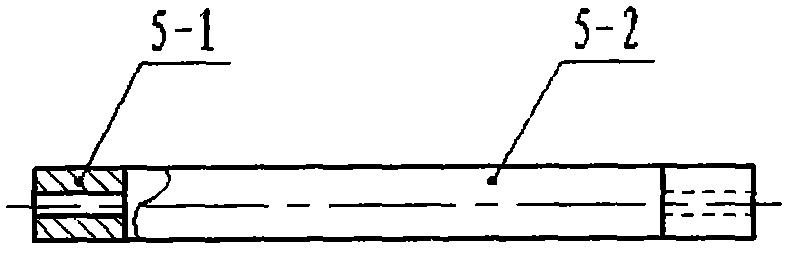

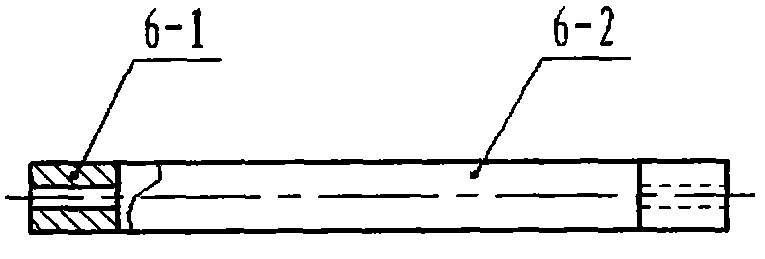

[0030] Such as figure 1 and figure 2 As shown, the following device is used for impregnating natural plant fibers with molten resin: comprising a melt impregnation mold 1 and a cooling roll pressing device 2, wherein the melt impregnation mold 1 includes a mold cavity, a material inlet and 4 to 8 parts located in the mold cavity A pair of dipping rollers, the pair of dipping rollers is installed in the U-shaped groove 1-1 of the mould, each pair of dipping rollers is composed of an upper dipping roller 6, a lower dipping roller 5 and a dipping roller spring 7, and the upper dipping roller 6 is composed of an upper dipping roller The fixed circle 6-1 and the upper impregnated roller shaft 6-2 are composed, the lower impregnated roller is composed of the lower impregnated roller fixed circle 5-1 and the lower impregnated roller shaft 5-2, and the upper impregnated roller 6 and the lower impregnated roller 5 are cylinders Shaped, installed in the molten impregnation mold 1 by m...

Embodiment 2

[0039] The device used in this embodiment is the same as in Embodiment 1.

[0040] Combing the continuous jute fibers into strips to obtain continuous jute fiber strips;

[0041] Heat and melt the impregnation mold at 1 to 200°C and keep it warm for a period of time;

[0042] Open the melting impregnation mold 1, the continuous jute fiber strip is passed between several pairs of dipping rolls 5 and the upper dipping roll 6, the dipping roll spring 7 makes the upper and lower dipping rolls have a certain pressure to improve the friction between the fibers, thereby Improving the traction strength of the natural fiber strips, while adding the plasticized low-density polyethylene molten resin from the feed port 4 to the melting impregnation mold 1, so that the continuous natural fiber strips and the thermoplastic resin melt are melt-impregnated;

[0043] The continuous jute fiber strip soaked and wrapped by the low-density polyethylene molten resin passes between the upper press ...

Embodiment 3

[0046] The device used in this embodiment is the same as in Embodiment 1.

[0047] Combing the continuous ramie fibers into strips to obtain continuous ramie fiber strips;

[0048] Heat and melt the impregnation mold at 1 to 210°C and keep it warm for a period of time;

[0049] Open the melting impregnation mold 1, pass the continuous ramie fiber strip between several pairs of dipping rollers 5 and 6, and the dipping roller spring 7 makes the upper and lower dipping rollers have a certain pressure to improve the friction between the fibers, thereby Improving the traction strength of the natural fiber strips, while adding the plasticized high-density polyethylene molten resin from the feed port 4 to the molten impregnation mold 1, so that the continuous natural fiber strips and the thermoplastic resin melt are melt-impregnated;

[0050] The continuous ramie fiber strip soaked and wrapped by the high-density polyethylene molten resin passes between the upper pressure roller 9 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com