Plastic pipe enhanced by continuous fiber winding

A plastic pipe, winding and strengthening technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as technical defects, limitations of use conditions, economic performance problems, etc., to achieve low cost, light weight, high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

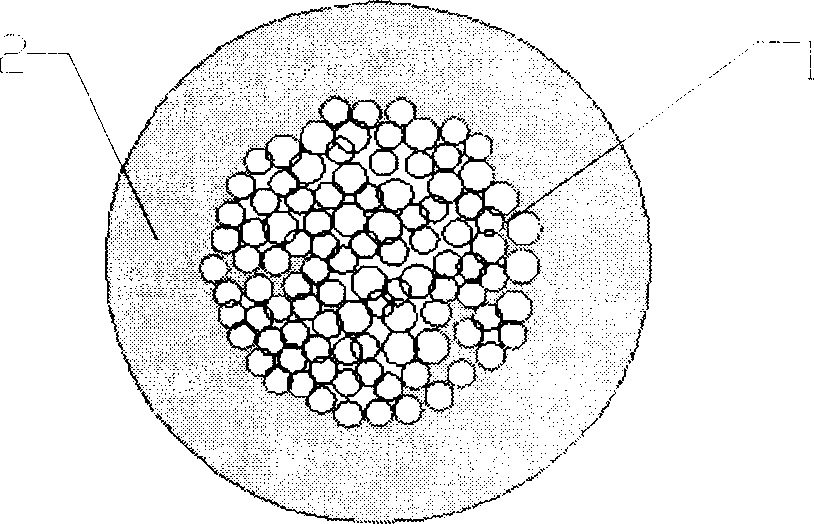

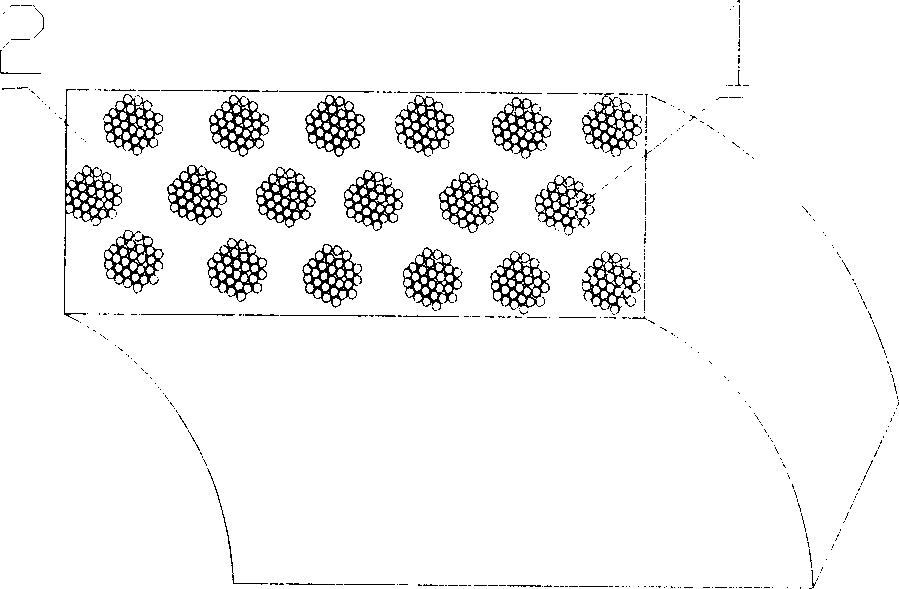

[0018] The long glass fiber is extruded through the wire coating machine head into such as figure 1 As shown in the composite wire, glass fiber 1 is alkali-free E glass fiber with a diameter of 0.013mm, the tow is made of 2000 monofilaments, and the surface is treated with a silane coupling agent, and the glass fiber coating material 2 is ethylene vinyl acetate copolymer (EVA18 / 3), the coating thickness is 0.2mm. The tensile strength of the coated wire was 280MPa. Pre-coat the bottom layer of high-density polyethylene on a stainless steel drum with a diameter of 1000mm, and then heat the surface with a heating source, wind the EVA-coated glass fiber wire on this layer of pipe, and then cover it with a layer of high-density polyethylene material (PE80 grade), repeat 4 times to reach a wall thickness of 40mm.

[0019] The inner diameter of the obtained pipe is 1000mm, the wall thickness is 40mm, and the pressure test pressure is 3.0MPa. According to the stress calculation, th...

Embodiment 2

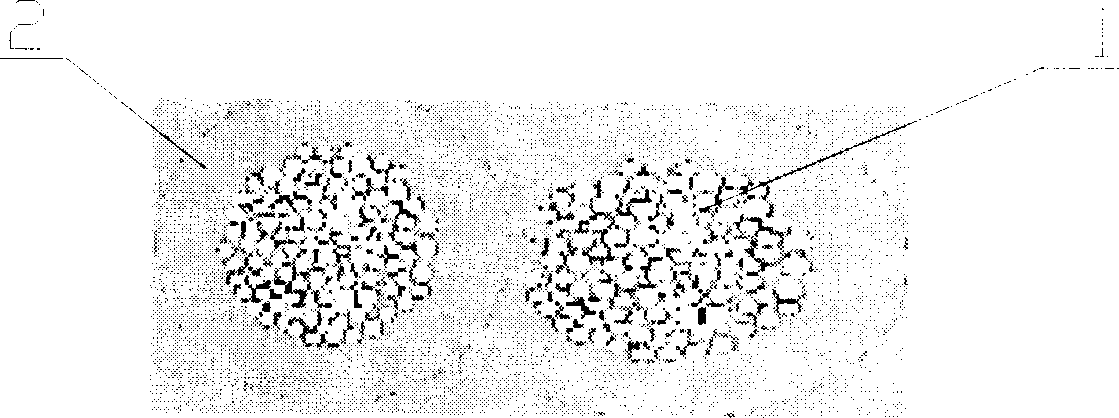

[0021] The long glass fiber is extruded through the wire coating machine head into such as figure 2 In the composite wire shown, the glass fiber 1 is alkali-free E glass fiber with a diameter of 0.013mm. Covering thickness is 2.0mm. The coated wire is directly wound on a stainless steel drum with a diameter of 1000mm, and then the surface is heated with a heating source, and then covered layer by layer, repeated several times until the wall thickness reaches 40mm.

[0022] The inner diameter of the obtained pipe is 1000mm, the wall thickness is 40mm, and the pressure test pressure is 3.0MPa. According to the stress calculation, the material grade is PE250.

Embodiment 3

[0024] The long glass fiber is extruded through the wire coating machine head into such as figure 1 As shown in the composite wire, the glass fiber 1 is alkali-free E glass fiber with a diameter of 0.013mm, the tow is made of 2000 monofilaments and strands, the surface is treated with a silane coupling agent, and the glass fiber coating material 2 is ethylene acrylic acid copolymer EAA , Coating thickness is 0.2mm. The tensile strength of the coated wire was 280 MPa. Pre-coat the bottom layer of high-density polyethylene on a stainless steel drum with a diameter of 1000mm, and then heat the surface with a heating source, wind the glass fiber wire coated with EAA on this layer of tubing, and then cover with a layer of high-density polyethylene Material HDPE6100M, repeated winding until the wall thickness reaches 40mm.

[0025] The inner diameter of the obtained pipe is 1000mm, the wall thickness is 40mm, and the pressure test pressure is 3.0MPa. According to the stress calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com