Production equipment and method for long fiber reinforced thermoplastic

A technology to strengthen thermoplastic and long fibers, applied in the direction of coating, can solve the problems of not maximizing the infiltration effect, limited work efficiency, limited monofilament spreading, etc., to achieve good impregnation effect, not easy to break, continuous production capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the technical scheme of this method is described in detail.

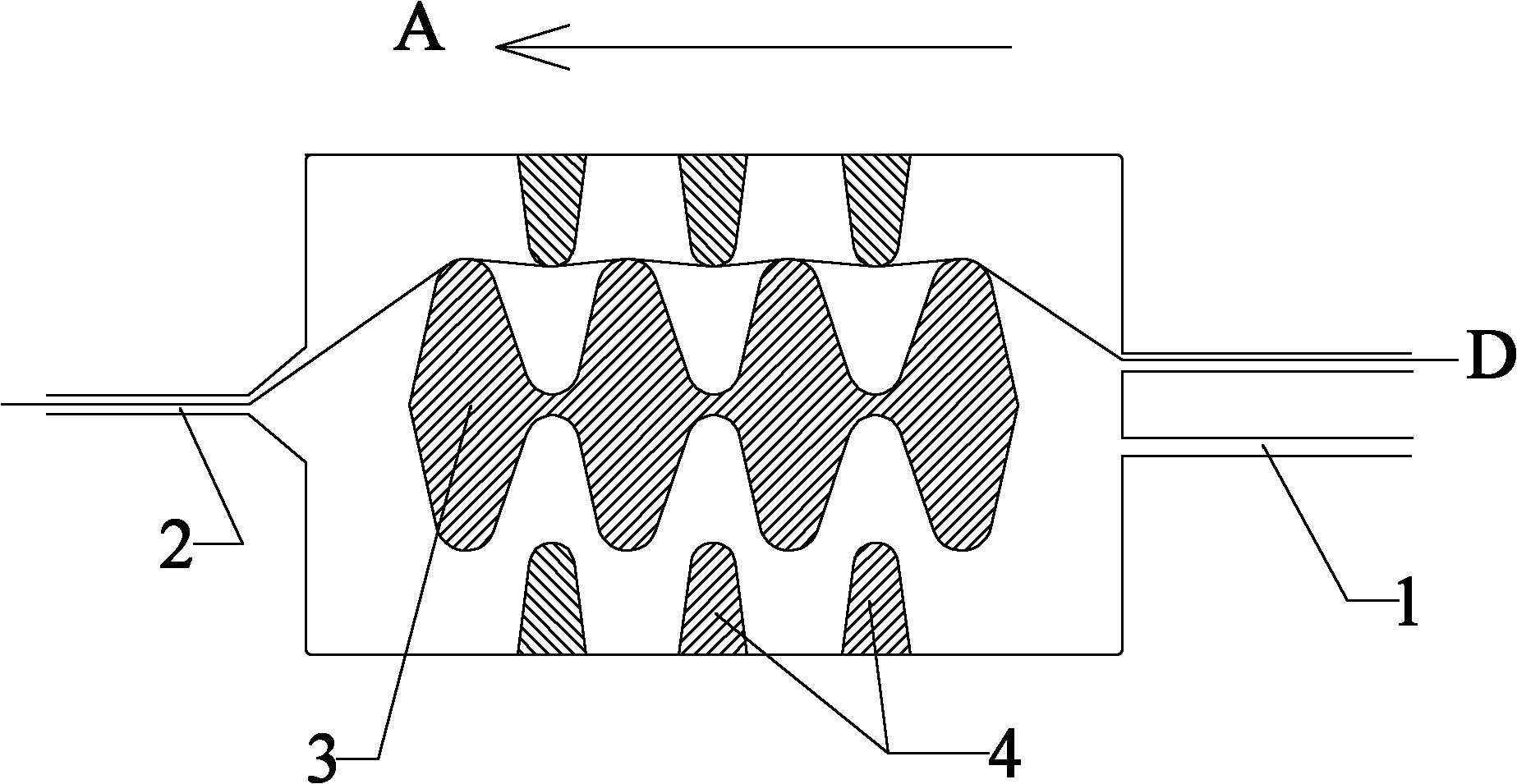

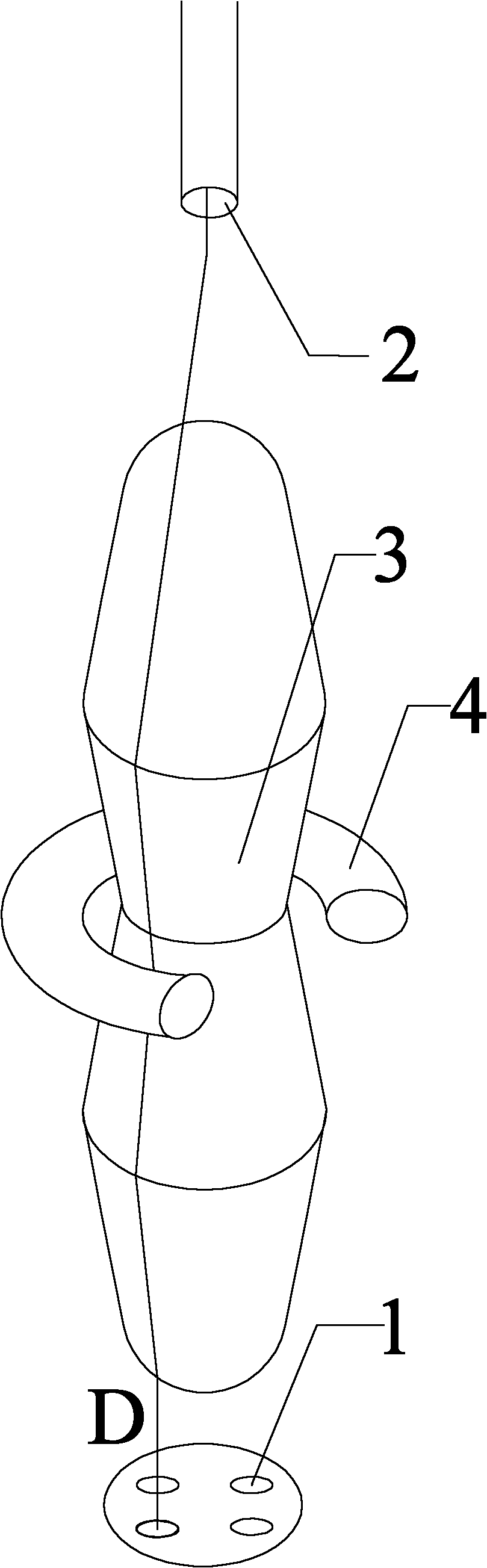

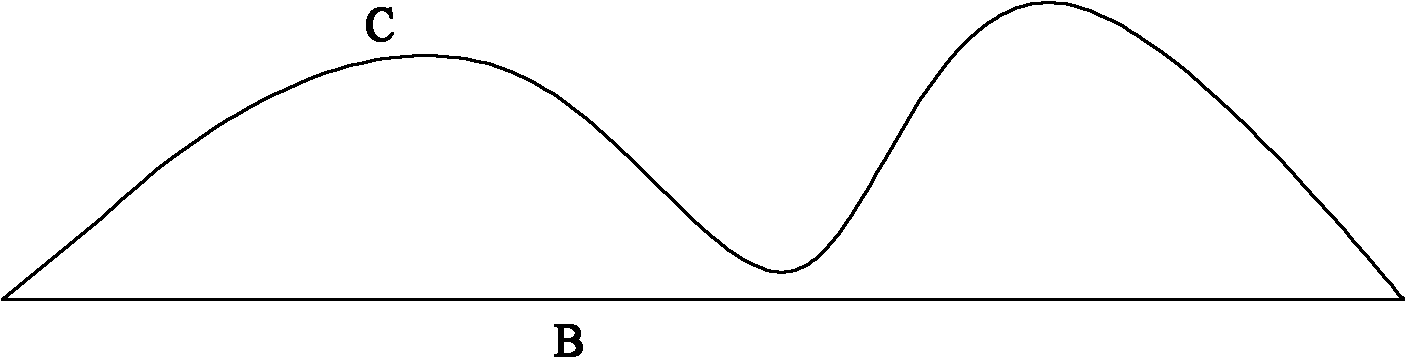

[0039] figure 1 It is a structural schematic diagram of a preferred solution of the raw yarn dispersion structure of the present invention; figure 2 It is a schematic diagram of the three-dimensional structure of another preferred solution of the raw yarn dispersion structure of the present invention; image 3 It is a schematic diagram of the positional relationship between the curve and the straight line forming the core of the loose yarn of the present invention.

[0040] refer to figure 1 and figure 2 , the raw yarn dispersion structure in the present invention comprises more than two yarn feeding through holes 1 whose axes are parallel to each other, and the yarn feeding through holes 1 are distributed centrally symmetrically on a cross section perpendicular to the axial direction, including the axes and the yarn feeding through holes. The axis of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com